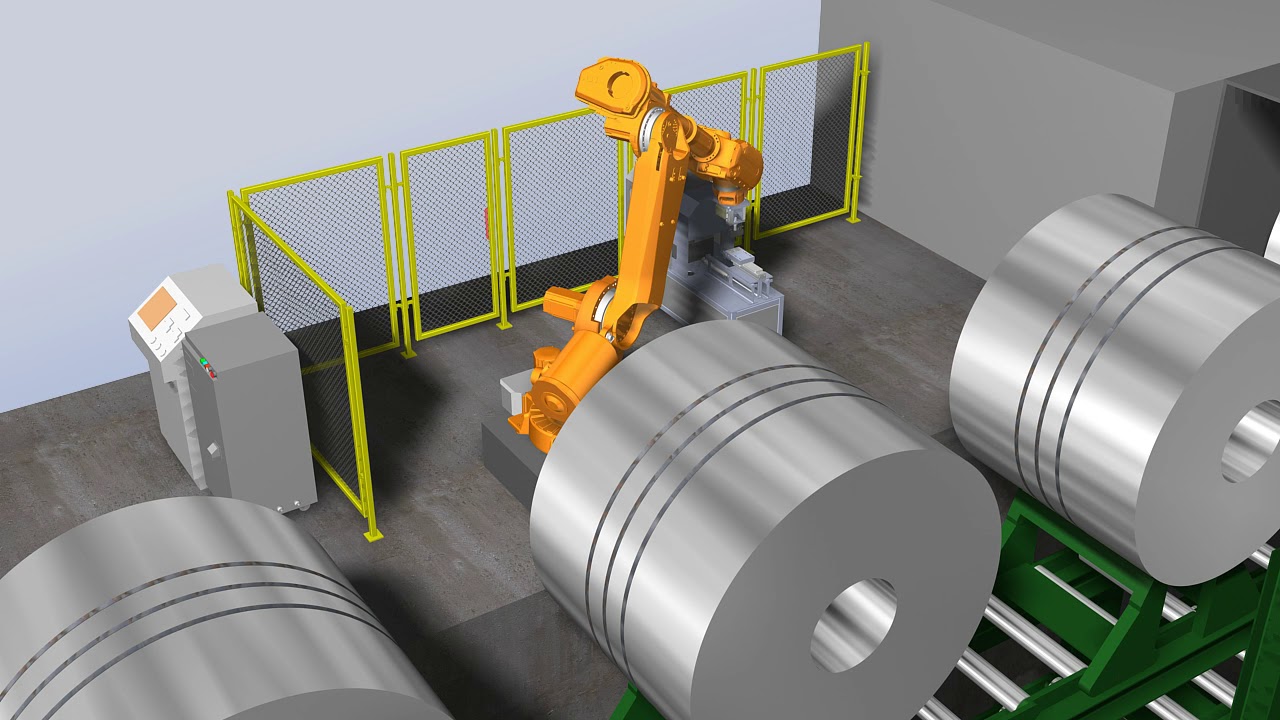

Robotic Handling Systems

Robotic Handling Systems

1,Increased Efficiency: Robotic Handling Systems can perform tasks quickly and accurately, improving overall efficiency in handling operations.

2,Cost Savings: By automating manual handling tasks, Robotic Handling Systems reduce labor costs and minimize errors or damage to products or materials.

3,Flexibility: These systems can be programmed to handle a wide range of products or materials, offering versatility and adaptability to changing production needs.

4,Improved Safety: Robotic Handling Systems minimize the risk of workplace accidents by reducing manual handling, lifting heavy loads, or exposure to hazardous materials.

5,Enhanced Consistency: With precise and consistent movements, these systems ensure uniformity in handling processes, leading to higher product quality and customer satisfaction.

Robotic Handling Systems

Robotic Handling Systems, Fanuc Industrial Robots, Assembly Line Robots, and Industrial Robotics Companies are essential components in modern manufacturing and logistics processes.

Robotic Handling Systems automate material handling tasks, improving efficiency and reducing labor costs. These systems can be tailored to meet specific handling requirements, ensuring versatility and adaptability.

Fanuc Industrial Robots provide advanced automation solutions with precise control and high-speed performance, offering solutions for a wide range of industrial applications.

Assembly Line Robots streamline production processes by automating assembly tasks, reducing cycle times, and ensuring consistent quality.

Industrial Robotics Companies provide a wide array of robotic solutions, from collaborative robots to advanced robotic systems, catering to the diverse needs of industries.

In conclusion, Robotic Handling Systems, Fanuc Industrial Robots, Assembly Line Robots, and Industrial Robotics Companies contribute to improved productivity, efficiency, and quality in manufacturing and logistics operations.