Robotics Technology And Flexible Automation Solution

Advantages of Robotics Technology And Flexible Automation Solution:

1,Increased Productivity: Robotics technology and flexible automation have the advantage of significantly increasing productivity in various industries. Robots can work at a faster pace and with consistent accuracy compared to human workers. With the ability to handle repetitive tasks and work continuously, robots can achieve higher production output and reduce cycle times, leading to improved overall productivity.

2,Enhanced Efficiency: The integration of robotics technology and flexible automation improves efficiency in manufacturing processes. Robots can perform tasks with precision and reliability, minimizing errors and rework. They can also operate 24/7, eliminating the need for breaks and shift changes. This increased efficiency translates to reduced downtime, optimized resource utilization, and streamlined workflow, resulting in cost savings and improved resource productivity.

3,Improved Safety: Robotics technology contributes to improved safety in the workplace. By automating hazardous or physically demanding tasks, robots reduce the risk of accidents and injuries to human workers. They can handle heavy loads, work in confined spaces, and operate in dangerous environments, ensuring the safety and well-being of employees. This advantage creates a safer work environment and reduces the potential liability for companies.

Please Contact Us For Detailed Technical Parameters.

Robotics Technology And Flexible Automation Solution:

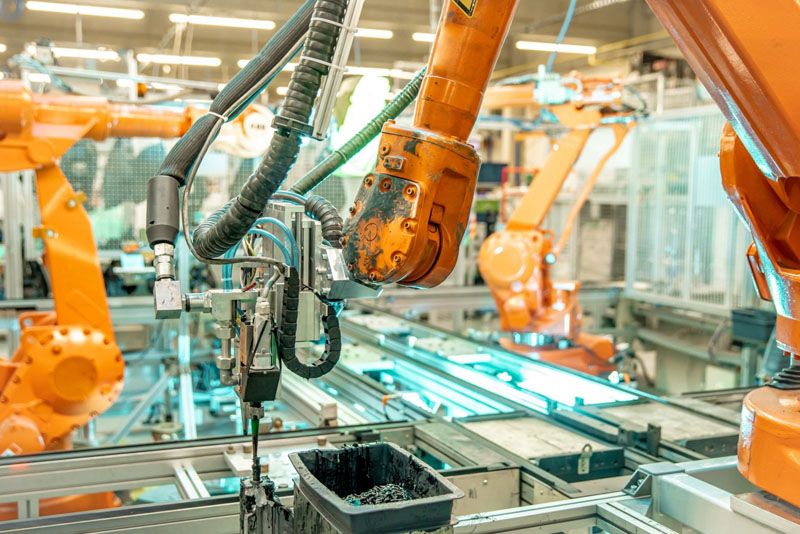

Robotics technology and flexible automation have revolutionized various industries. Robotics Technology And Flexible Automation Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters.Fanuc industrial robots, known for their precision and reliability, have become popular choices for businesses seeking to automate their processes. These robots excel in tasks such as welding, assembly, and material handling, helping businesses increase efficiency and reduce production costs.

One industry that has greatly benefited from robotics is the pharmaceutical industry. Robotics in the pharmaceutical industry has enabled accurate and efficient drug manufacturing, packaging, and labeling processes. These robots ensure precise dosage measurements, reduce the risk of contamination, and enhance overall quality control, leading to safer medications for patients.

Another noteworthy development in robotics is the Mecademic robot arm. With its compact size and high precision, the Mecademic robot arm is suitable for delicate tasks in industries like electronics and research laboratories. Its flexibility and ease of integration make it an ideal choice for applications that require precise movements in confined spaces.

In conclusion, robotics technology, exemplified by Fanuc industrial robots, is transforming diverse industries. Robotics in the pharmaceutical industry and the emergence of innovative robot arms such as Mecademic are paving the way for enhanced productivity, quality, and efficiency. As technology continues to advance, we can expect even more groundbreaking applications of robotics in various sectors.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

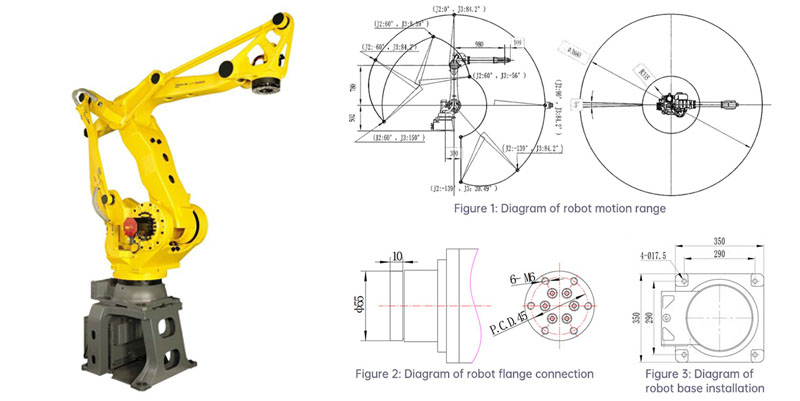

DIMENSIONAL DRAWINGS:

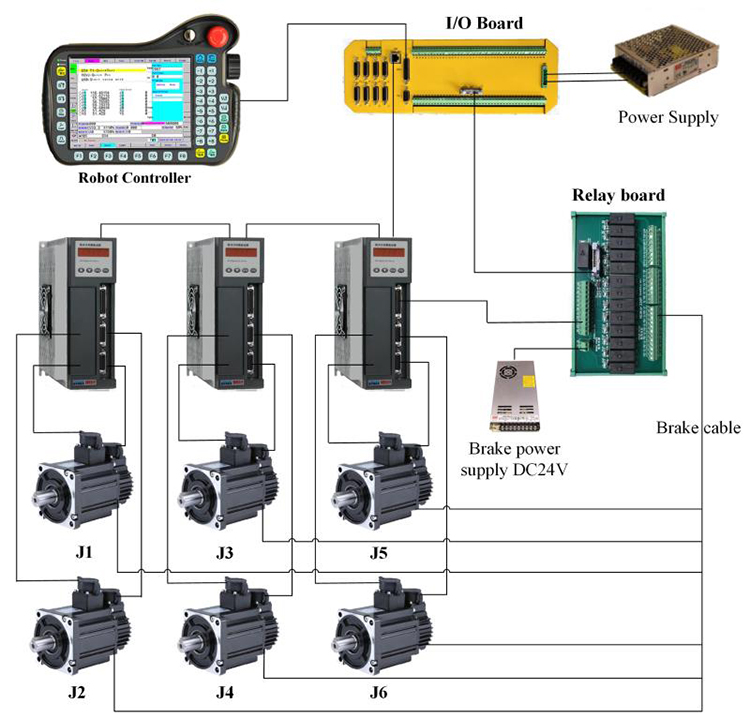

ROBOT CONTROLSYSTEM:

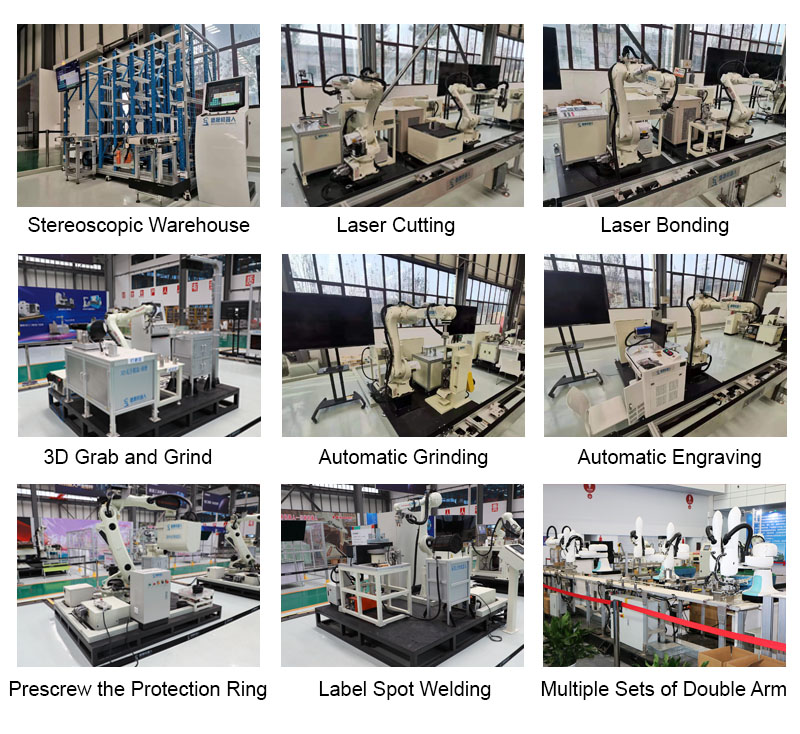

APPLICATIONS:

1,Industrial Manufacturing: Robotics technology and flexible automation have revolutionized the manufacturing industry by streamlining production processes and improving efficiency. Robots can perform repetitive tasks with precision and speed, such as assembly, welding, painting, and material handling. Flexible automation allows for quick reprogramming and adaptation to different product lines, enabling manufacturers to respond to changing market demands effectively.

2,Healthcare: Robotics technology has found widespread application in the healthcare sector. Surgical robots assist surgeons in performing complex procedures with enhanced precision and minimal invasiveness, leading to faster recovery times for patients. Robotic exoskeletons help individuals with mobility impairments regain movement and independence. Additionally, robots automate repetitive tasks in hospitals, such as medication delivery, inventory management, and patient care, freeing up healthcare professionals to focus on more critical and complex tasks.

3,Logistics and e-commerce: With the rise of e-commerce and the increasing demand for timely and accurate order fulfillment, robotics technology and flexible automation have become crucial in the logistics industry. Autonomous robots can navigate warehouses, pick and pack items, and optimize inventory storage, significantly improving efficiency and reducing order processing times. These technologies enable warehouses to operate 24/7, handle large volumes of orders, and adapt quickly to peaks in demand, ensuring faster and more reliable delivery to customers.

FEATURES:

1,Increased efficiency: Robotics technology and flexible automation systems are designed to streamline and optimize production processes. By using advanced robotics, companies are able to perform tasks more quickly and with a higher level of accuracy, resulting in improved productivity and operational efficiency.

2,Flexibility: One of the key advantages of robotics technology and flexible automation is their ability to adapt to changing production needs. These systems can be easily programmed and reprogrammed to perform different tasks and handle different products, allowing for greater flexibility in manufacturing processes.

3,Improved safety: Robotics technology and flexible automation systems can help improve workplace safety by taking over hazardous or repetitive tasks that may pose a risk to human workers. By automating these tasks, companies can reduce the likelihood of accidents and injuries, creating a safer working environment.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: