Robotics And Manufacturing

Advantages of Robotics And Manufacturing:

1,Improved Efficiency: Robotics and manufacturing offer the advantage of improved efficiency in production processes. Robots can perform repetitive tasks with high speed and accuracy, resulting in faster production cycles and increased productivity. This efficiency allows manufacturers to meet higher demand and reduce production costs.

2,Enhanced Quality and Precision: Robotics enables manufacturers to achieve higher levels of quality and precision in their products. Robots are programmed to perform tasks with consistent accuracy, minimizing human errors and variation. This results in improved product quality, reduced waste, and higher customer satisfaction.

3,Increased Safety: Robotics and manufacturing also contribute to increased workplace safety. By automating hazardous or physically demanding tasks, robots help protect human workers from potential injuries and accidents. This creates a safer working environment and reduces the risk of occupational hazards.

Robotics And Manufacturing:

Robotics and manufacturing play a crucial role in modern industries. With the rise of automation, industrial robotics companies like Kuka Kr 150 have emerged as leaders in the field. Kuka Kr 150 offers high-performance industrial robots that are widely used in manufacturing processes.

These robots are equipped with advanced technology and can perform a range of tasks with precision and efficiency. From assembly line operations to material handling, Kuka Kr 150 robots excel in various applications.

Additionally, the availability of industrial robot parts further contributes to the success of robotics and manufacturing. These parts enable maintenance and repair of robots, ensuring their continuous operation. With access to quality robot parts from trusted manufacturers, industries can minimize downtime and keep production running smoothly.

Overall, the combination of robotics and manufacturing, along with the support of industrial robotics companies and the availability of robot parts, revolutionizes industrial processes. It enhances productivity, accuracy, and safety, making it an essential element in modern manufacturing operations.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

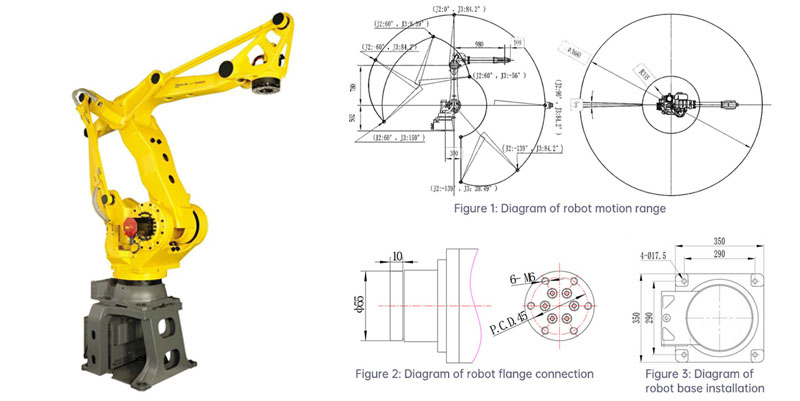

DIMENSIONAL DRAWINGS:

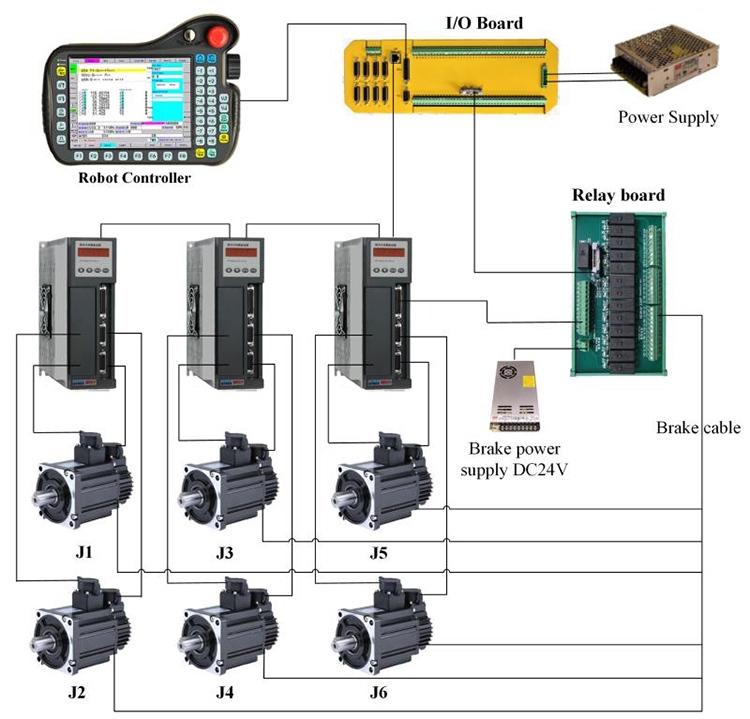

ROBOT CONTROLSYSTEM:

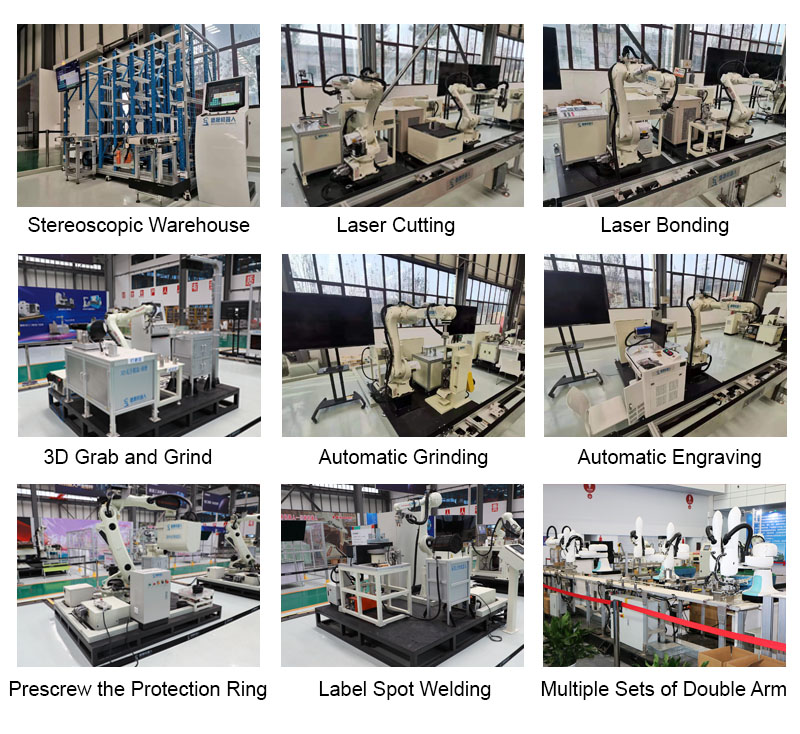

APPLICATIONS

1,Assembly and Production: Robotics is widely used in assembly and production processes across various industries. Robots can efficiently and accurately assemble components, perform intricate tasks, and handle repetitive tasks that would otherwise be time-consuming or prone to human error. This application of robotics in manufacturing leads to increased productivity and improved product quality.

2,Material Handling and Logistics: Another significant application of robotics in manufacturing is material handling and logistics. Robots can move heavy loads, palletize goods, and navigate complex warehouse environments with ease. By automating these tasks, manufacturers can streamline their supply chain, reduce errors, and improve efficiency in material handling and logistics operations.

3,Quality Control and Inspection: Robotics is also extensively used for quality control and inspection processes. Robots equipped with advanced sensors and vision systems can perform precise and consistent inspections, detecting defects or flaws in products. This application ensures that products meet quality standards and reduces the need for manual inspection, saving time and resources.

FEATURES:

1,Automation: One of the key characteristics of robotics and manufacturing is automation. Robotics allows for the automation of repetitive and mundane tasks, reducing the need for manual labor and increasing productivity. By automating processes such as assembly, material handling, and quality control, manufacturers can achieve higher efficiency, lower costs, and improved precision.

2,Flexibility and Adaptability: Robotics and manufacturing offer the advantage of flexibility and adaptability. Robots can be easily programmed and reprogrammed to perform different tasks, making them suitable for various applications and industries. This flexibility allows manufacturers to quickly respond to market changes, reconfigure production lines, and optimize processes based on demand and product variations.

3,Integration with Technology: Robotics and manufacturing are characterized by their integration with advanced technologies. Robots can be equipped with sensors, vision systems, artificial intelligence, and machine learning algorithms, enabling them to perform complex tasks with accuracy. Additionally, robotics integrates with other technologies such as data analytics, Internet of Things (IoT), and cloud computing, creating smart factories and enabling real-time monitoring, predictive maintenance, and data-driven decision-making.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: