It Robotic Automation

Advantages of It Robotic Automation:

1,Improved Efficiency: It Robotic Automation offers the advantage of improved efficiency in various industries. Robots can work at a faster pace and with consistent precision, reducing cycle times and increasing productivity. They can also perform repetitive tasks continuously without the need for breaks or rest, ensuring uninterrupted operations and optimized production output.

2,Enhanced Accuracy and Precision: Robotic automation ensures high levels of accuracy and precision in performing tasks. Robots are programmed to perform tasks with minimal errors, resulting in improved product quality and reduced rework. This advantage is particularly beneficial in industries where precision is crucial, such as manufacturing, where even small variations can have significant implications on the final product.

3,Increased Safety and Ergonomics: It Robotic Automation prioritizes safety by reducing human exposure to hazardous environments and minimizing the risk of physical injuries. Robots can handle heavy loads, work in confined spaces, and perform dangerous tasks, ensuring the safety and well-being of human workers. Additionally, automation eliminates monotonous and repetitive tasks, reducing the risk of strain and musculoskeletal injuries in workers.

It Robotic Automation:

It Robotic Automation, including assembly line robots, has become increasingly prevalent in various industries, including the construction industry. Industrial mobile robots have revolutionized how tasks are performed, bringing unprecedented efficiency and productivity.

Assembly line robots play a vital role in manufacturing. They can accurately perform repetitive tasks, such as picking and placing components, tightening screws, and performing quality inspections. This automation streamlines production, reduces errors, and increases output.

In the construction industry, robotics has also made significant progress. Robotics in construction bring several advantages, from improved safety and productivity to enhanced precision and cost savings. Industrial mobile robots are being used to execute tasks like bricklaying, concrete pouring, and demolition, providing accuracy and efficiency that surpass traditional methods.

Furthermore, robotics in the construction industry also offers a solution to challenges like labor shortages and worker safety. It reduces human involvement in hazardous activities and allows for continued operation in adverse conditions.

In conclusion, It Robotic Automation, including assembly line robots and industrial mobile robots, has transformed industries. Its impact on the construction industry, in particular, has brought efficiency, precision, and improved safety to various tasks. The integration of robotics promises to shape the future of construction and other industries, offering numerous benefits to companies and workers alike.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

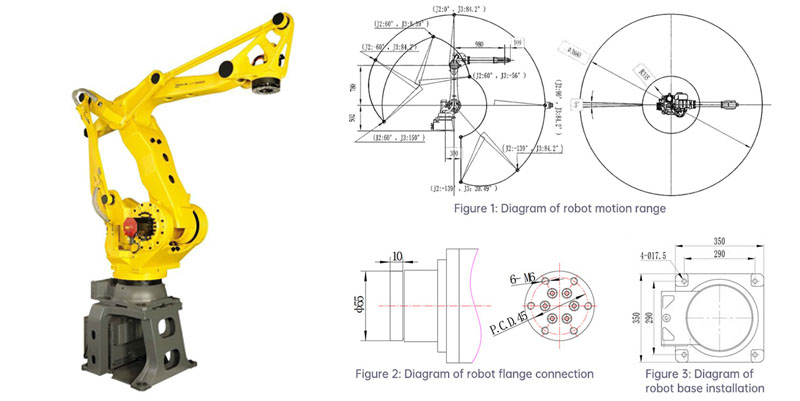

DIMENSIONAL DRAWINGS:

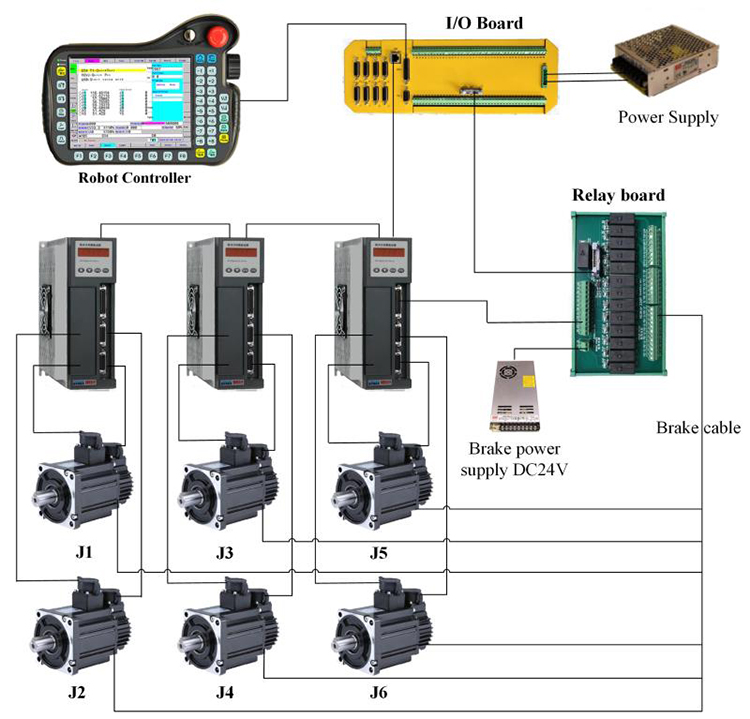

ROBOT CONTROLSYSTEM:

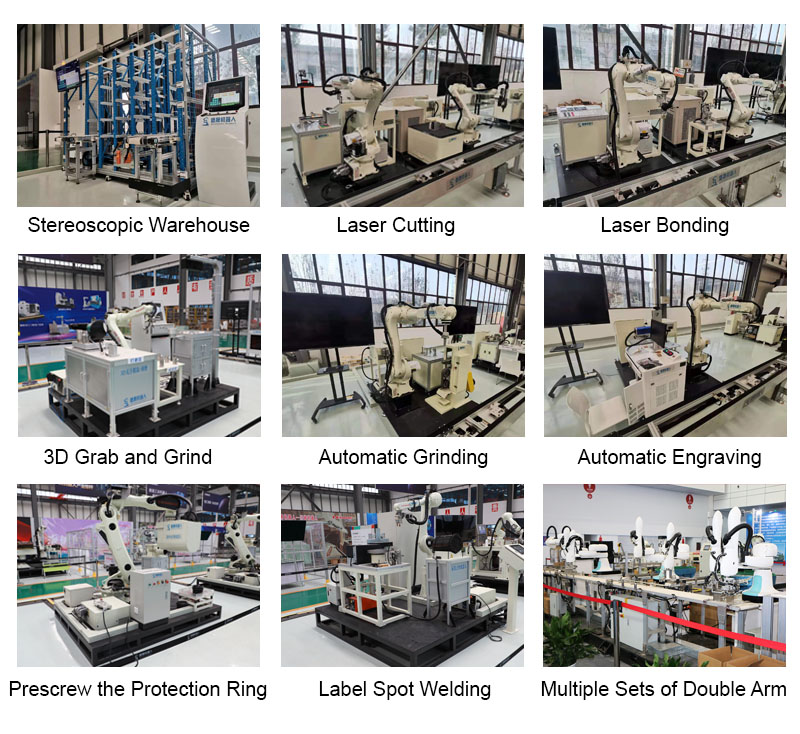

APPLICATIONS:

1,Manufacturing and Assembly: It Robotic Automation finds extensive application in manufacturing and assembly processes. Robots can perform a wide range of tasks, such as assembling components, handling materials, and packaging finished products. This automation streamlines production, increases efficiency, and improves product quality.

2,Logistics and Warehousing: It Robotic Automation is also widely used in logistics and warehousing operations. Robots can be deployed for material handling, sorting, and inventory management tasks. With the ability to navigate complex warehouse environments and interact with other systems, they optimize logistics processes, reduce errors, and enhance overall efficiency in supply chain management.

3,Healthcare and Medical Fields: It Robotic Automation is increasingly being adopted in healthcare and medical industries. Robots can assist in surgical procedures, perform tasks in laboratory settings, and provide support in patient care. With their precision and reliability, robotic automation improves patient outcomes, reduces human error, and enhances the overall quality of healthcare delivery.

FEATURES:

1,Versatility: One of the key characteristics of It Robotic Automation is its versatility. Robots can be programmed and configured to perform a wide range of tasks, making them adaptable to various industries and applications. Whether it's assembly line operations, material handling, or complex surgical procedures, robotics can be customized to meet specific requirements and perform tasks with precision.

2,Flexibility: It Robotic Automation offers flexibility in terms of operation and integration. Robots can be easily programmed and reprogrammed to adapt to changing production demands or process requirements. They can also integrate seamlessly with existing systems and equipment, allowing for efficient collaboration and communication. This flexibility enhances operational efficiency and enables manufacturers to optimize their processes and respond quickly to market changes.

3,Advanced Technology Integration: It Robotic Automation is characterized by its integration with advanced technologies. Robots can incorporate sensors, vision systems, artificial intelligence, and machine learning algorithms, enabling them to perform complex tasks with high levels of accuracy and efficiency. Integration with technologies such as data analytics and IoT further enhances their capabilities, allowing for real-time monitoring, predictive maintenance, and data-driven decision-making.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

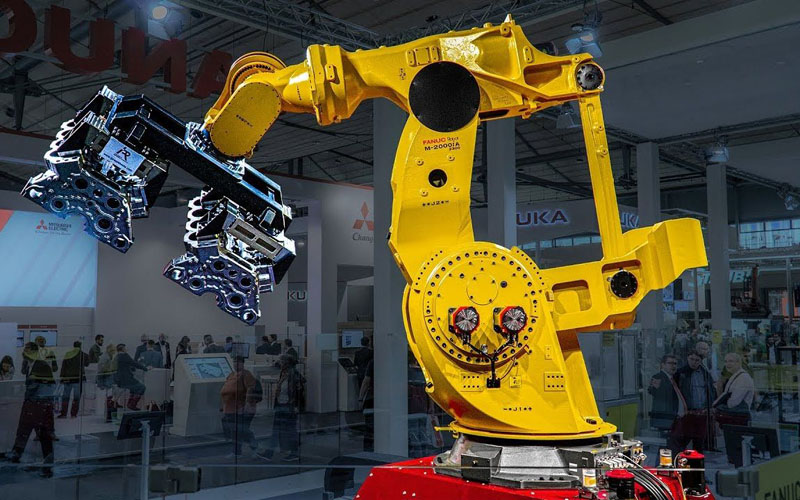

EXHIBITION:

MORE PRODUCTS:

CONTACT US: