Robotics In Foundry Solution

Robotics In Foundry Solution:

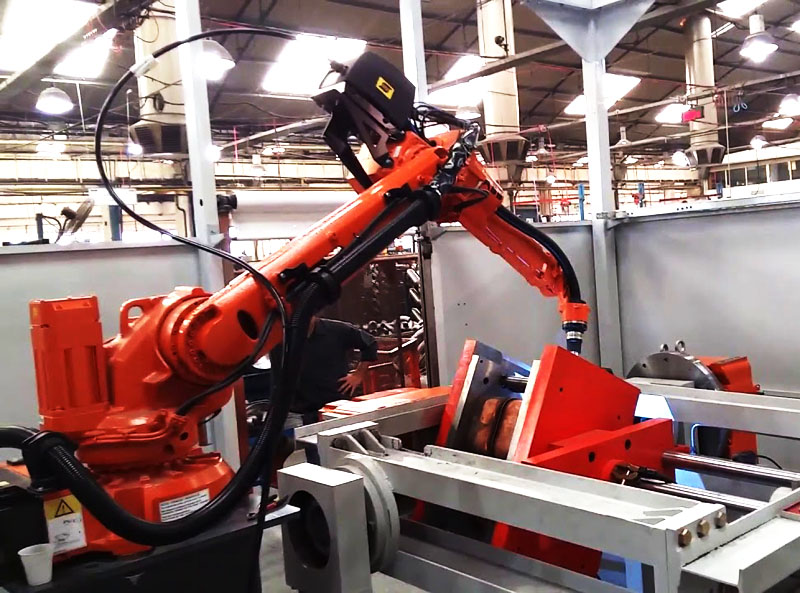

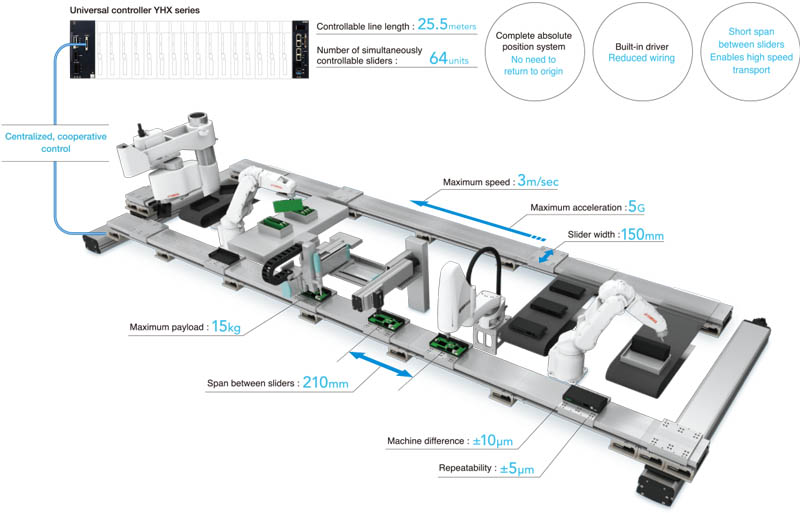

1,Increased productivity: Robotics in foundry operations can significantly increase productivity by automating repetitive and labor-intensive tasks. Robots can work continuously without breaks, resulting in improved production rates and reduced cycle times.

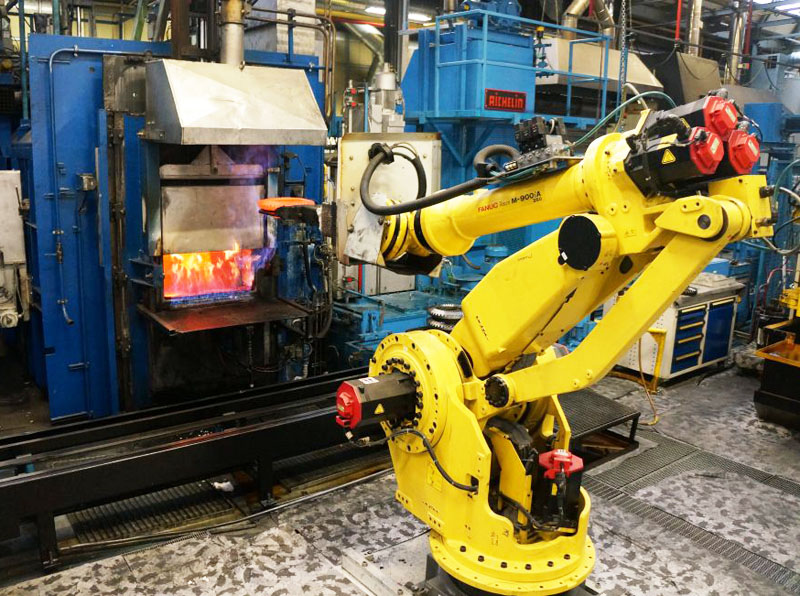

2,Improved worker safety: Foundry operations can be hazardous, with high temperatures and exposure to molten metal. Utilizing robots in foundries reduces the risk of accidents and injuries to human workers. Robots can handle tasks in dangerous environments, minimizing the need for human intervention in hazardous areas.

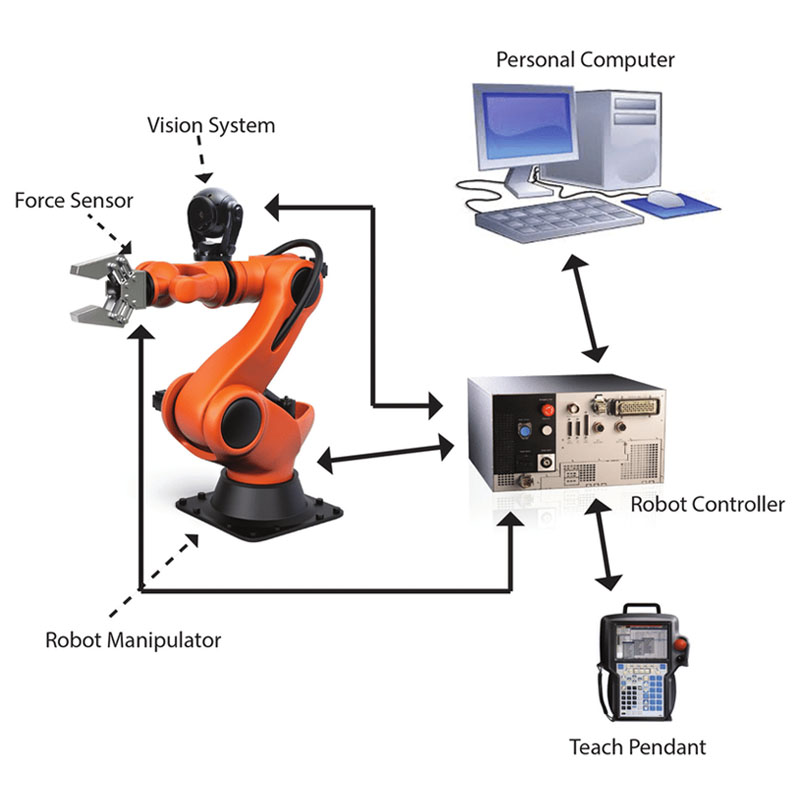

3,Enhanced accuracy and precision: Robots in foundries can perform tasks with high precision and accuracy, ensuring consistent quality in casting processes. They can consistently pour molten metal, manipulate and position molds, and perform precise finishing tasks. This improves casting quality and reduces the chances of defects or rework.

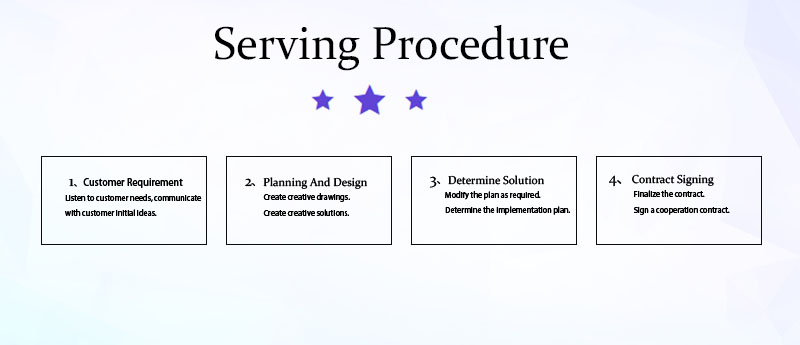

Please Contact Us For Detailed Technical Parameters.

Robotics In Foundry Solution:

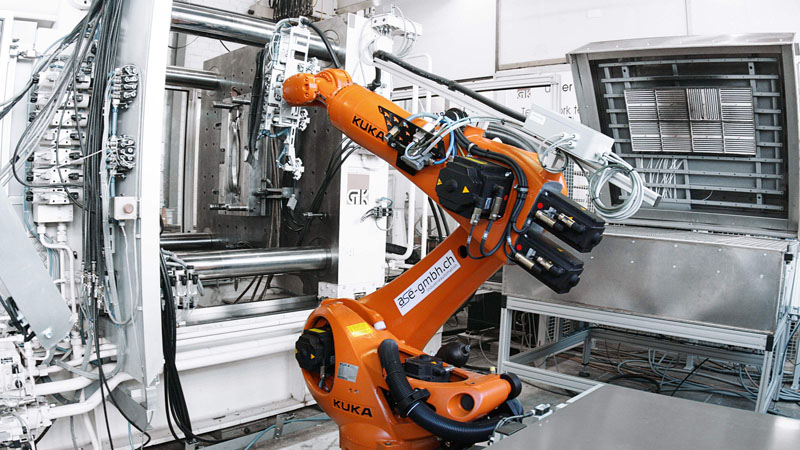

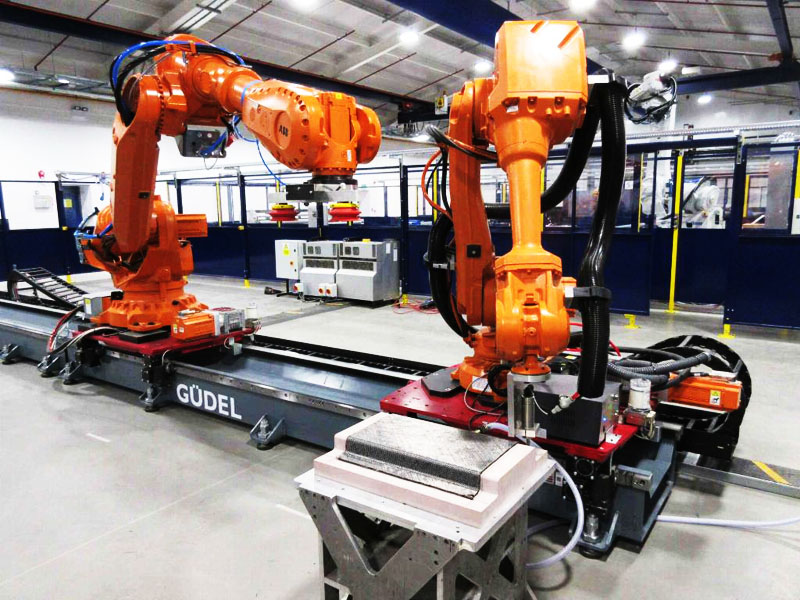

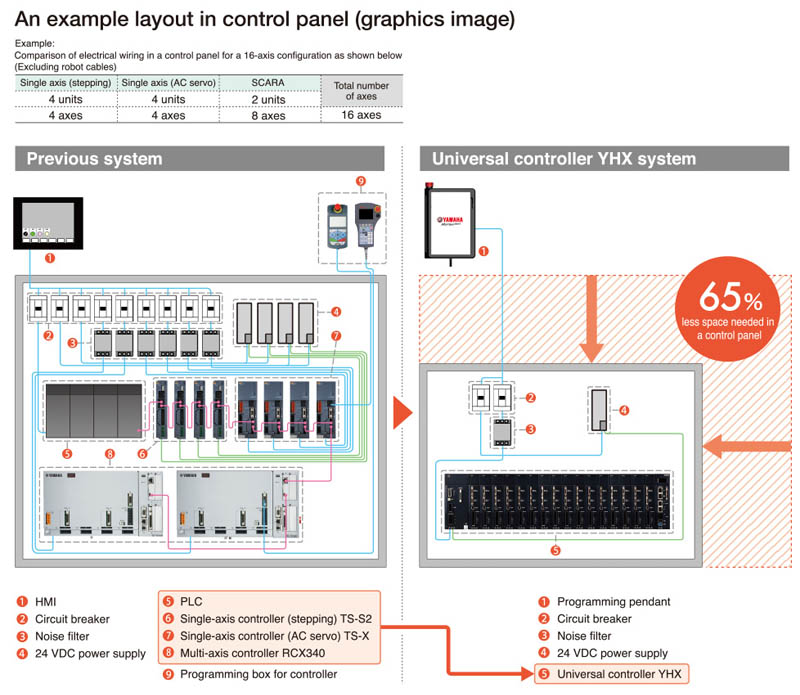

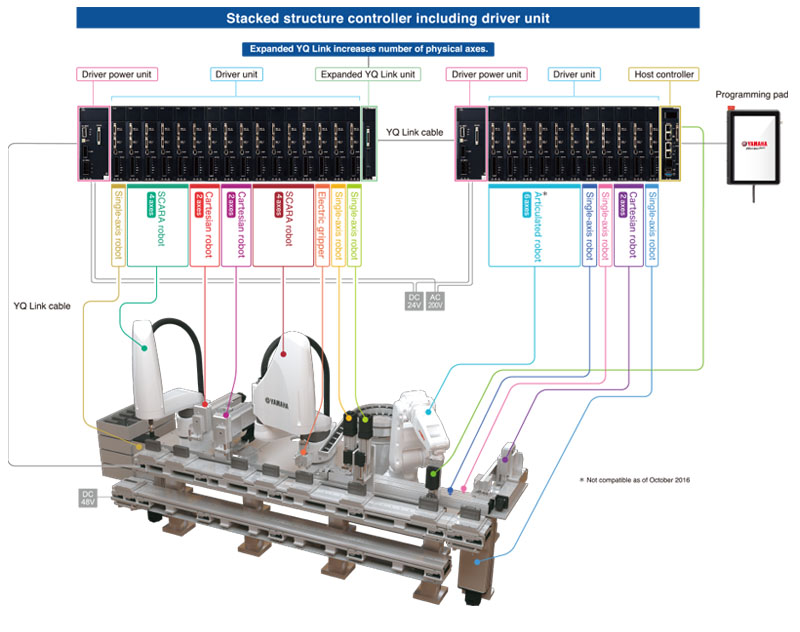

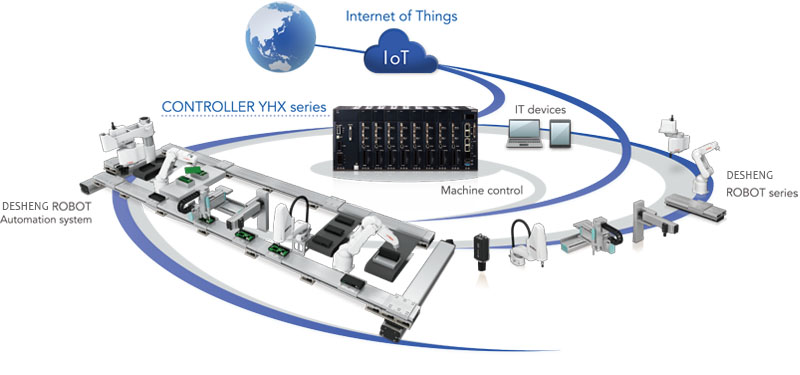

Robotics in foundry is characterized by automation, precision, and efficiency. Robotics In Foundry Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters. These robots are designed to handle high-temperature, high-risk tasks such as pouring molten metal, removing castings, and finishing operations. They are programmed to perform repetitive tasks with high accuracy, reducing human error and increasing productivity. Robotics in foundry also improves worker safety by performing dangerous tasks, reducing exposure to harmful environments. Furthermore, they are adaptable and can be reprogrammed for different tasks, providing flexibility in production. The use of robotics in foundry also leads to cost savings in the long run by reducing labor costs and increasing efficiency.