Robotics In Foundry Solution

Robotics In Foundry Solution:

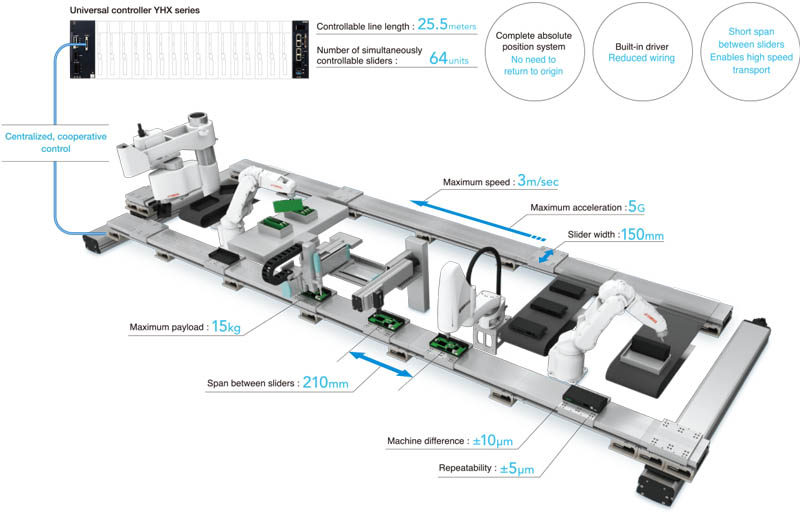

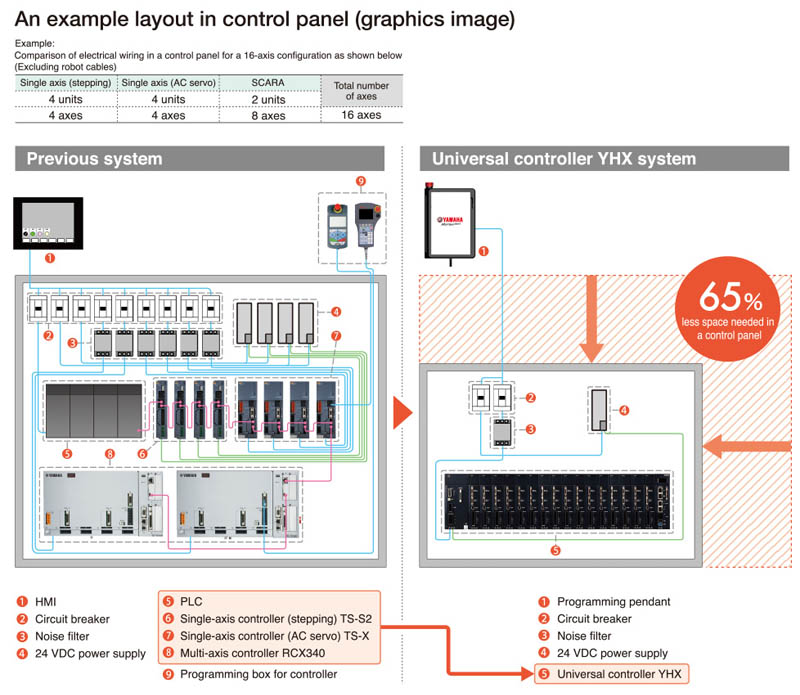

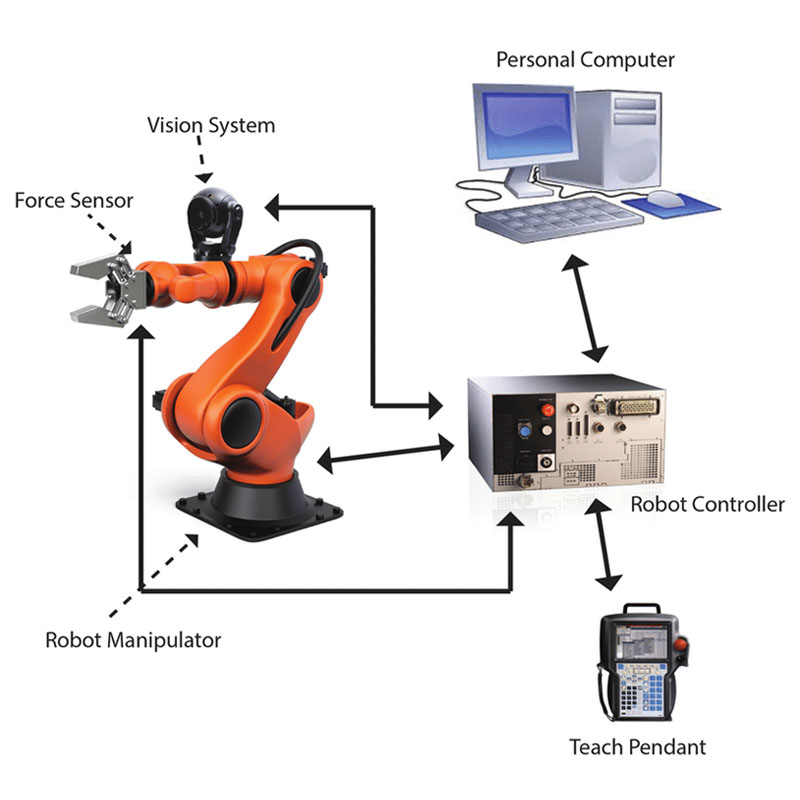

1,Increased efficiency: Robotics in foundries can greatly improve efficiency by automating tasks such as material handling, pouring, and finishing. Robots can work at a consistent pace without breaks or fatigue, leading to faster production and reduced cycle times.

2,Improved worker safety: Foundry operations can be dangerous, exposing workers to high temperatures, heavy equipment, and hazardous materials. Utilizing robots in the foundry industry can help minimize these risks by handling dangerous tasks, reducing the likelihood of accidents and injuries to human workers.

3,Enhanced precision and accuracy: Robots in foundries can perform tasks with a high level of precision and accuracy. They can precisely pour molten metal into molds, consistently handle and position parts, and perform intricate finishing tasks. This results in improved casting quality and reduces the risk of defects or inconsistencies.

Please Contact Us For Detailed Technical Parameters.

Robotics In Foundry Solution:

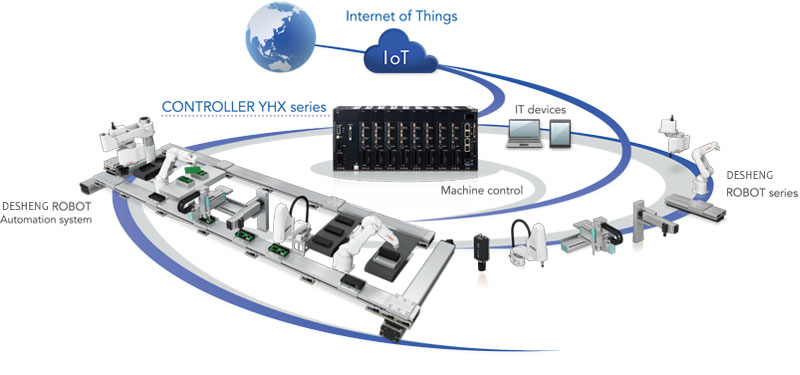

Robotics in foundry applications has revolutionized the manufacturing industry. Robotics In Foundry Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters.Robots are used for tasks such as casting, molding, and finishing, reducing human involvement and increasing efficiency and precision. They can withstand harsh conditions, including high temperatures and dust, ensuring consistent production quality. Robots also enhance safety by performing dangerous tasks, minimizing workplace injuries. In addition, they are programmable and can be customized to meet specific production requirements. This automation technology reduces operational costs and boosts productivity, making it an integral part of modern foundries.