Robot In Foundry Solution

Robot In Foundry Solution:

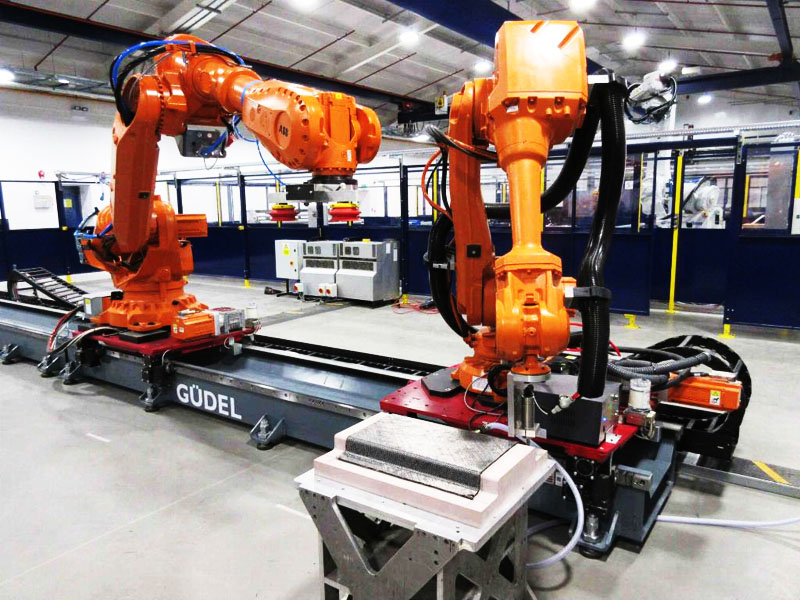

1,Increased productivity: Robots in foundry operations can work continuously and at a consistent pace, resulting in improved production rates and reduced cycle times. They can handle repetitive tasks efficiently, freeing up human workers for more complex or skilled work.

2,Improved worker safety: Foundry environments can be hazardous, with high temperatures and exposure to molten metal. Robots can handle dangerous tasks and operate in these harsh conditions, reducing the risk of accidents and injuries to human workers.

3,Enhanced precision and quality control: Robots in foundries can perform tasks with high precision and accuracy. They can precisely pour molten metal, manipulate molds, and perform intricate finishing operations. This helps to ensure consistent quality in casting processes, reducing defects and scrap.

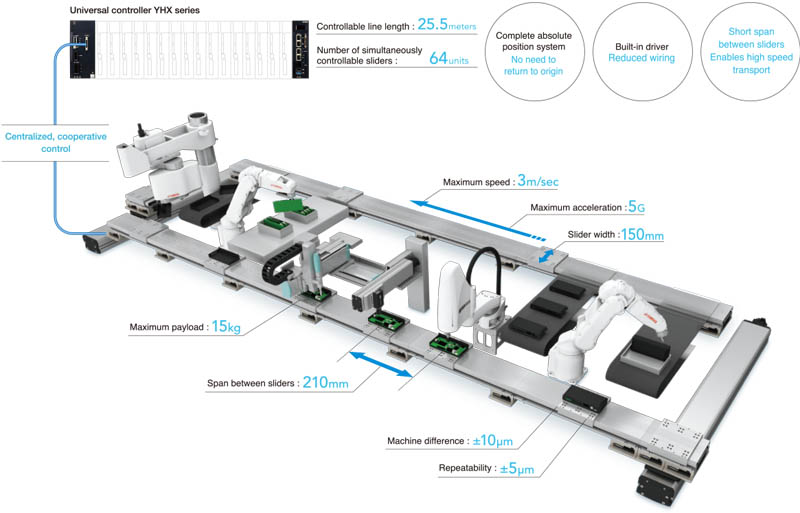

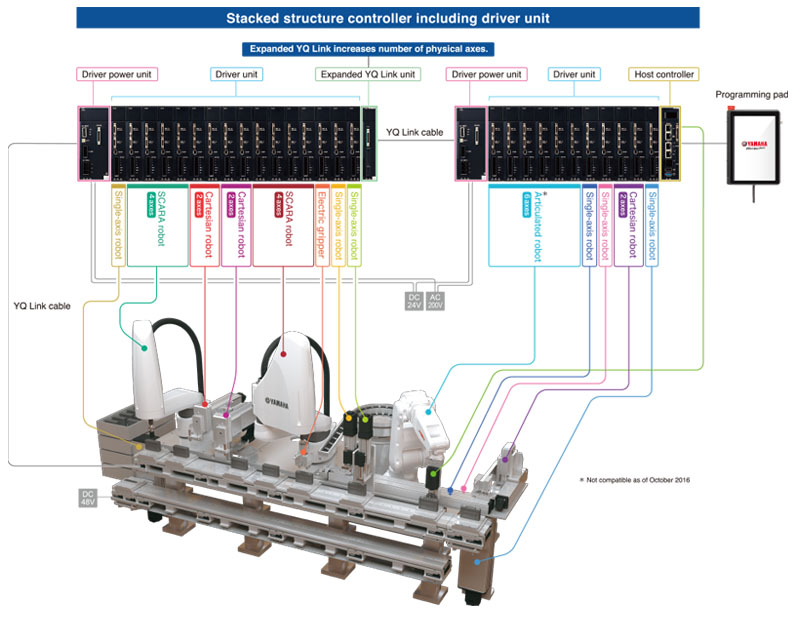

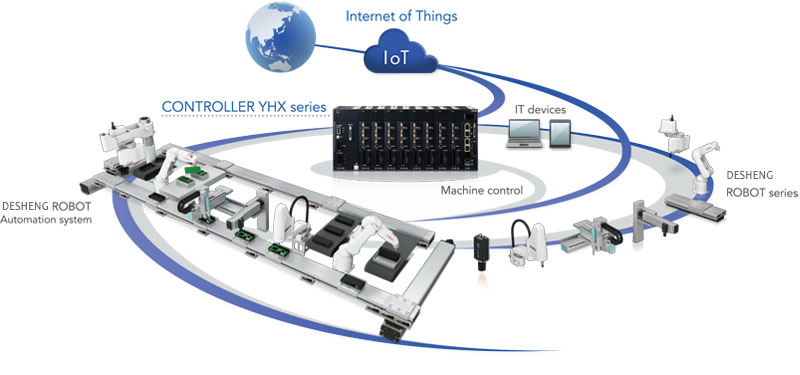

Please Contact Us For Detailed Technical Parameters.

Robot In Foundry Solution:

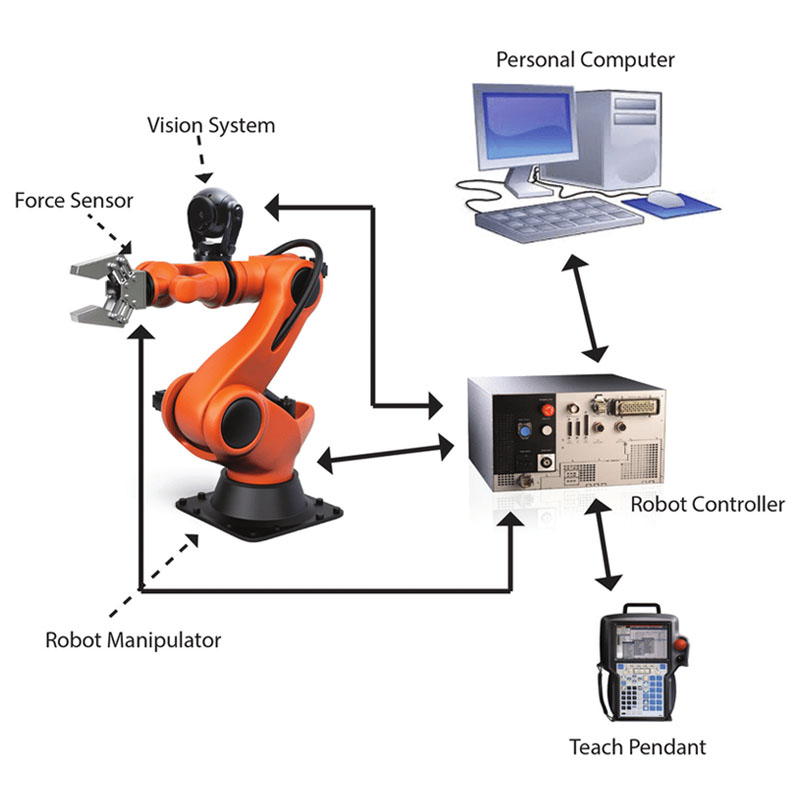

Robots in a foundry are used to automate tasks such as pouring, casting, and finishing. To use them, first, program the robot with the specific task it needs to perform. This could be done using a software interface provided by the robot manufacturer. Then, position the robot in the correct place in the production line. Ensure safety measures are in place to protect human workers. Monitor the robot's performance regularly and make necessary adjustments to its programming. Regular maintenance is also key to ensure the robot's longevity and efficiency. Remember, proper training is required to operate these robots safely and effectively.