Robotics For Foundry Solution

Robotics For Foundry Solution:

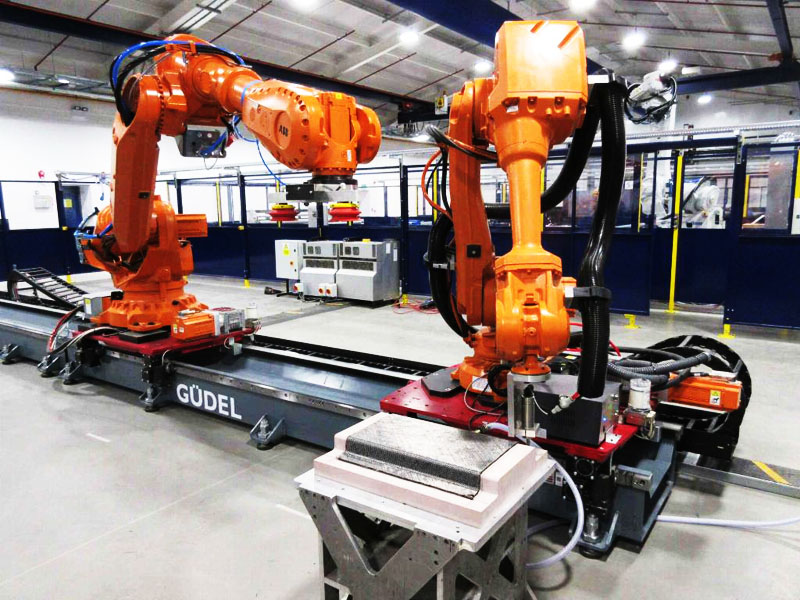

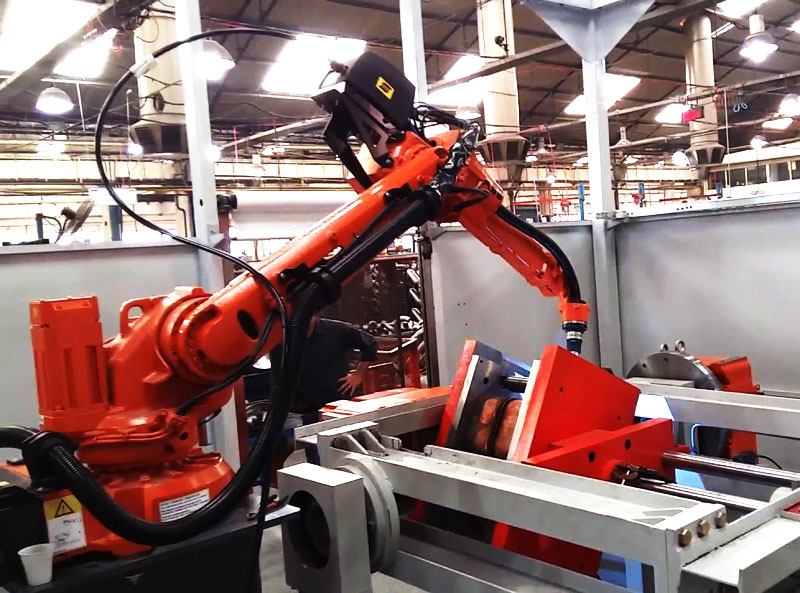

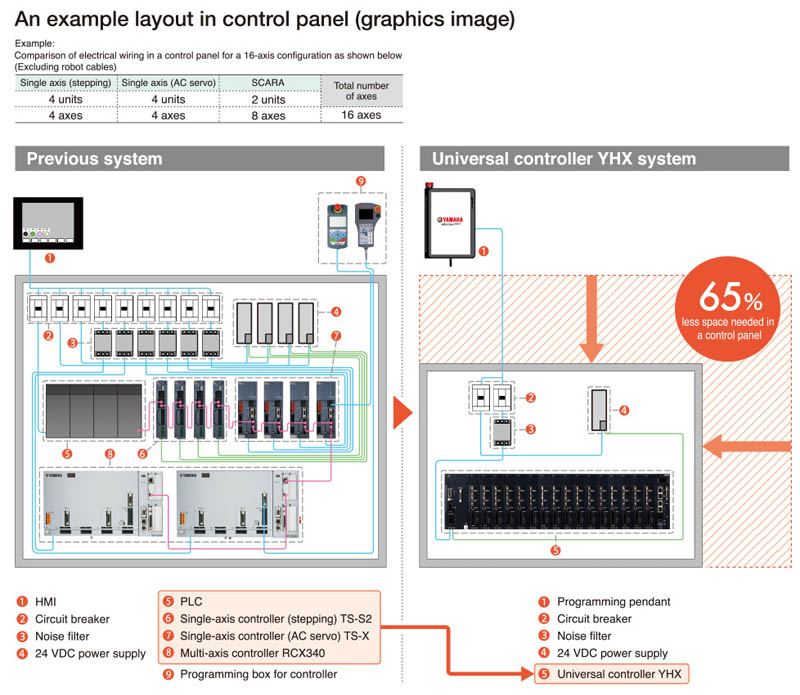

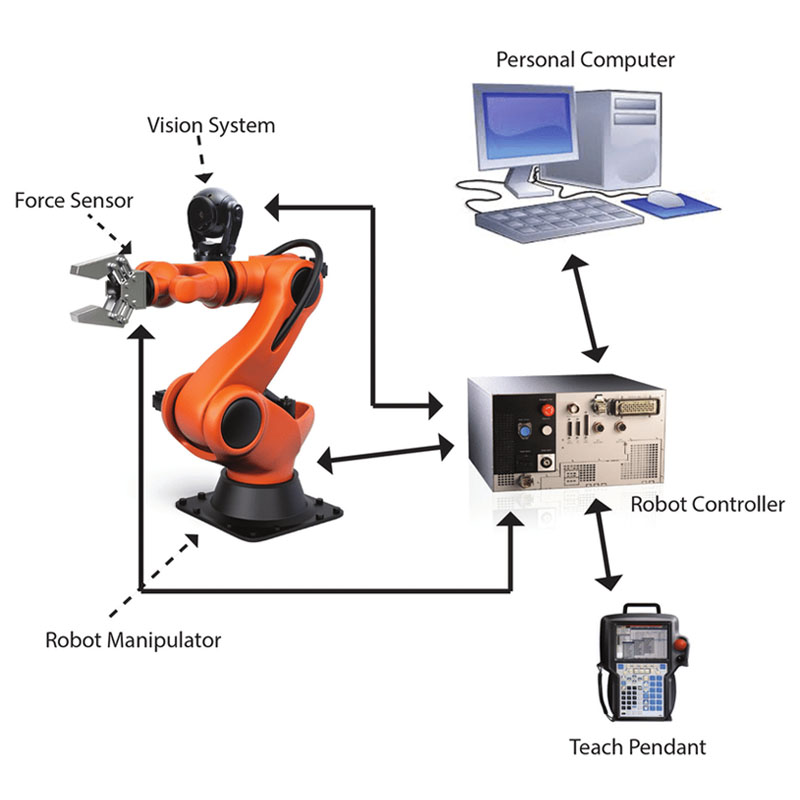

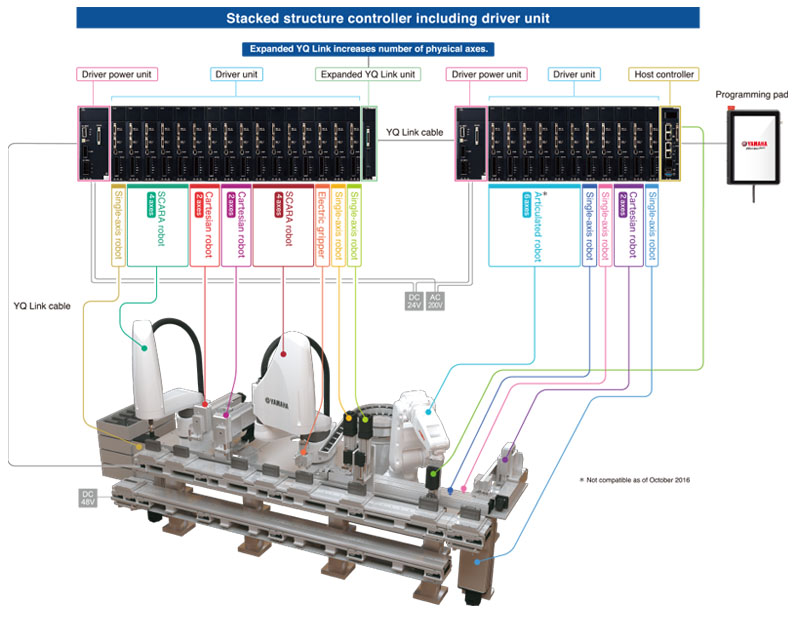

1,Increased efficiency and productivity: Robotics in foundry operations automate tasks like material handling and pouring, leading to faster production and reduced cycle times.

2,Improved safety: Robots handle hazardous tasks, reducing the risk to human workers in foundry environments.

3,Enhanced precision and quality control: Robots perform tasks with high accuracy, ensuring consistent quality in casting processes and reducing defects.

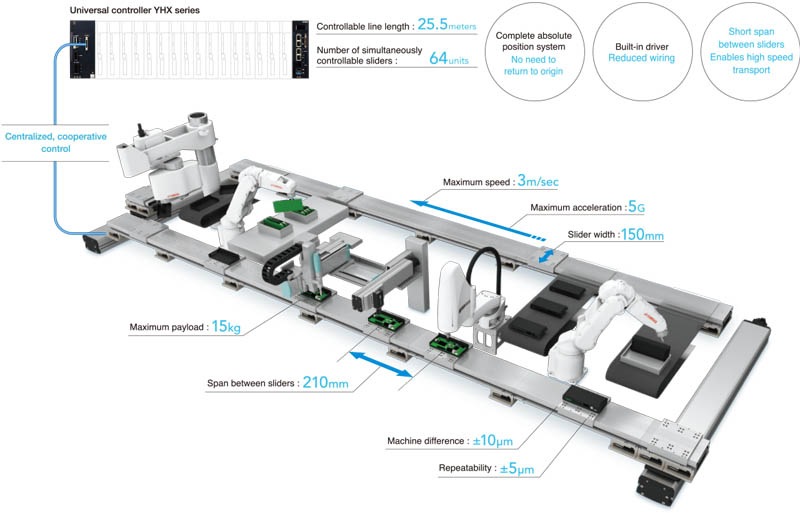

Please Contact Us For Detailed Technical Parameters.

Robotics For Foundry Solution:

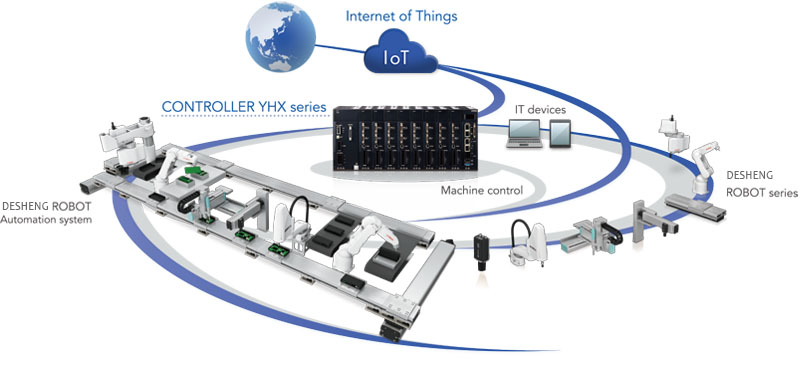

The future of robotics in the foundry industry looks promising. With advancements in technology, robots can perform tasks with higher precision and speed, increasing productivity and reducing errors. They can also work in hazardous environments, improving safety standards. The integration of AI and machine learning can further enhance their capabilities, enabling predictive maintenance and real-time decision making. Furthermore, the adoption of robotics can lead to significant cost savings in the long run. However, the transition requires substantial investment and workforce re-skilling. Despite these challenges, the benefits of robotics in foundry make it a worthwhile investment for the future.