Robotic Process Automation Solution Tech

Robotic Process Automation Solution Tech:

1,Improved efficiency and productivity: RPA automates repetitive and rule-based tasks, enabling organizations to complete them faster and more accurately. This leads to increased efficiency and productivity by freeing up human workers to focus on more complex and strategic initiatives.

2,Error reduction and increased accuracy: RPA executes tasks with precision and consistency, minimizing the risk of human errors. By eliminating manual data entry and repetitive tasks, RPA technology ensures higher accuracy and reduces the need for rework or error correction.

3,Cost savings and resource optimization: By deploying RPA, organizations can achieve significant cost savings by reducing labor costs and improving operational efficiency. RPA can handle high volumes of work with minimal resources, allowing companies to allocate their workforce more effectively.

Please Contact Us For Detailed Technical Parameters.

Robotic Process Automation Solution Tech:

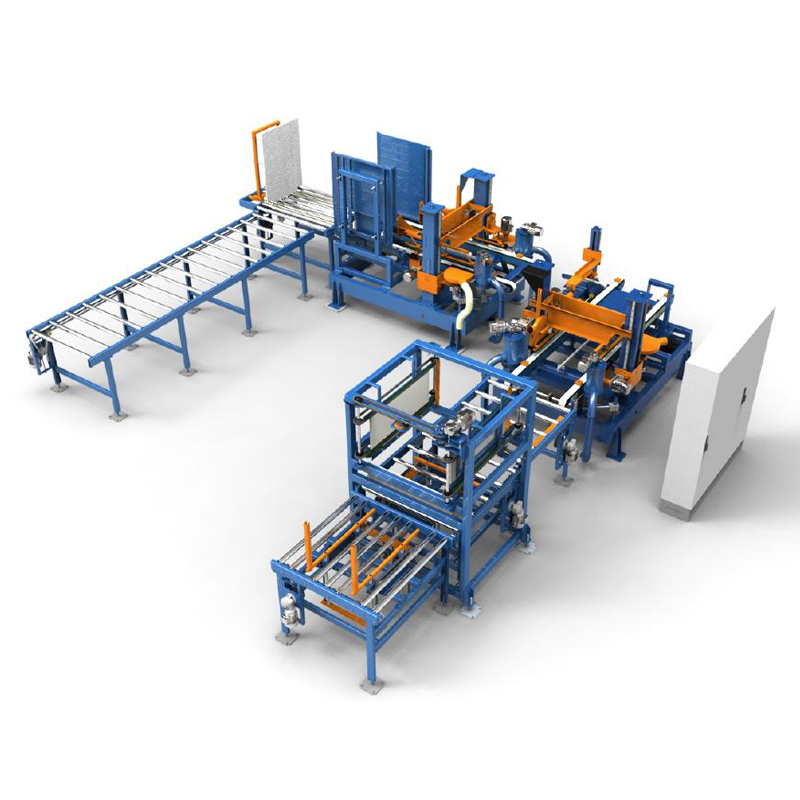

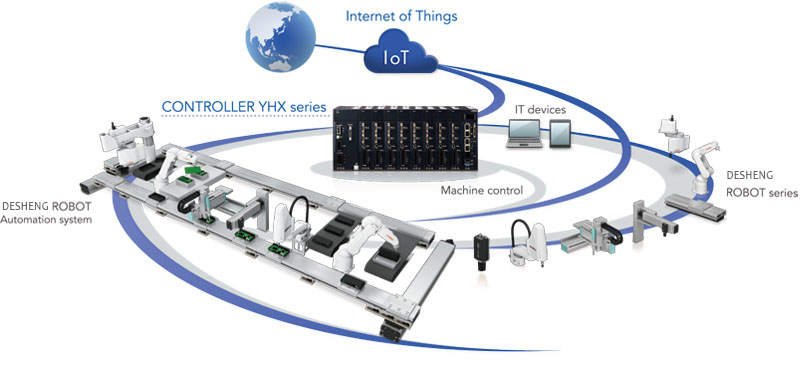

Robotic Process Automation (RPA) technology, together with industrial robotics solutions like palletizing robots for sale and Automated material handling robots, is revolutionizing various industries. Okibo Robot in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters.RPA technology automates repetitive tasks, streamlining processes and improving efficiency. Industrial robotics solutions, such as palletizing robots, automate the labor-intensive task of stacking and arranging pallets, optimizing productivity and reducing manual handling risks. Automated material handling robots offer efficient and accurate movement of materials, enhancing warehouse operations. By integrating RPA technology and industrial robotics solutions, businesses can experience increased productivity, reduced operational costs, and improved accuracy. These advanced technologies optimize workflows, minimize errors, and enhance overall performance. Embracing the power of Robotic Process Automation and industrial robotics solutions, companies can stay ahead in the rapidly changing and competitive market landscape.

| SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

| Robot Arm | Japanese Brand Robot | Fanuc | Kawasaki | |

| German Brand Robot | KUKA | |||

| Switzerland Brand Robot | ABB | |||

| Main Performance arameters | Speed Capacity | 8s Per Cycle | Adjust according to products and arrangement per layer | |

| Weight | About 8000kg | |||

| Applicable Product | Cartons,Cases,Bags, Pouch Bags | Containers,Bottles,Cans,Buckets etc | ||

| Power and Air Requirements | Compressed Air | 7bar | ||

| Electric Power | 17-25 Kw | |||

| Voltage | 380v | 3 Phases | ||

| PLC | Siemens | |||

| Frequency Converter | Danfoss | |||

| Photoelectric Sensor | Sick | |||

| Servo Motor | Panasonic | |||

| Pneumatic Component | SMC | |||

| Low-voltage Apparatus | Schneider | |||

| Touch Screen | SchneiderlSiemens | |||

| Driving Motor | SEW | |||

| SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

| Robot Arm | Japanese Brand Robot | Fanuc | Kawasaki | |

| German Brand Robot | KUKA | |||

| Switzerland Brand Robot | ABB | |||

| Main Performance arameters | Speed Capacity | 8s Per Cycle | Adjust according to products and arrangement per layer | |

| Weight | About 8000kg | |||

| Applicable Product | Cartons,Cases,Bags, Pouch Bags | Containers,Bottles,Cans,Buckets etc | ||

| Power and Air Requirements | Compressed Air | 7bar | ||

| Electric Power | 17-25 Kw | |||

| Voltage | 380v | 3 Phases | ||

| PLC | Siemens | |||

| Frequency Converter | Danfoss | |||

| Photoelectric Sensor | Sick | |||

| Servo Motor | Panasonic | |||

| Pneumatic Component | SMC | |||

| Low-voltage Apparatus | Schneider | |||

| Touch Screen | SchneiderlSiemens | |||

| Driving Motor | SEW | |||