Industrial Robotics Solutions

Industrial Robotics Solutions:

1,Increased productivity: Industrial robots can perform tasks faster and more efficiently than human workers, leading to higher production rates and improved overall productivity.

2,Enhanced precision and accuracy: Robots are engineered to perform repetitive actions with consistent precision, resulting in high-quality and accurate outputs. This reduces errors and improves product consistency.

3,Improved worker safety: By automating hazardous or physically demanding tasks, industrial robots help create a safer work environment for human workers, reducing the risk of injuries and ensuring their well-being.

Industrial Robotics Solutions:

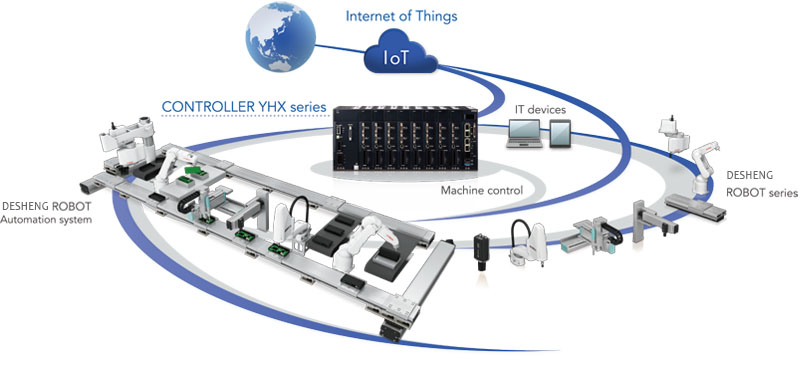

Industrial Robotics Solutions, including automotive robotics companies and robotics pharmaceutical automation, are revolutionizing various industries. One emerging technology in this field is the AGV (Automated Guided Vehicle) and AMR (Autonomous Mobile Robot). These robots are designed to autonomously navigate and transport materials, optimizing efficiency in production and logistics processes. Automotive robotics companies use these solutions to automate manufacturing tasks, improving productivity and ensuring consistency. Robotics pharmaceutical automation streamlines pharmaceutical production, from sorting and packaging to quality control, ensuring accuracy and reducing human errors. With the integration of AGVs and AMRs, industries benefit from increased efficiency, reduced labor costs, and improved safety. Industrial robotics solutions continue to drive innovation and transform businesses, revolutionizing the way tasks are performed in various sectors.

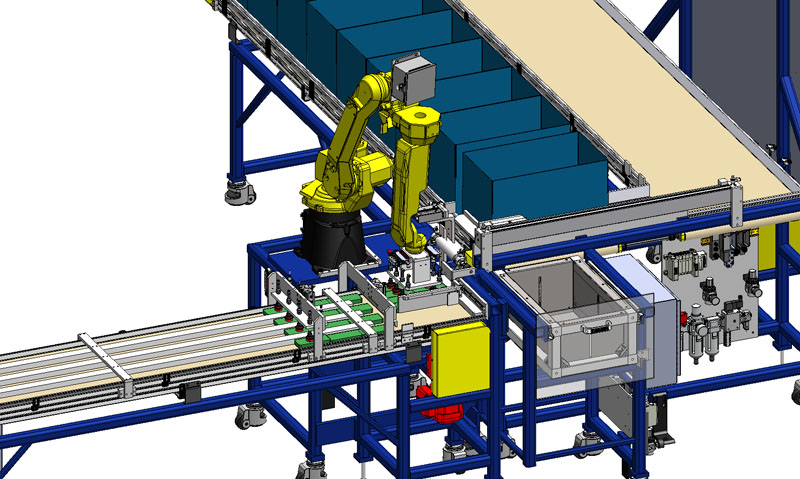

SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

Robot Arm | Japanese Brand Robot | Fanuc | Kawasaki | |

German Brand Robot | KUKA | |||

Switzerland Brand Robot | ||||

Main Performance | Speed Capacity | 8s Per Cycle | Adjust according to products and | |

Weight | About 8000kg | |||

Applicable Product | Cartons,Cases,Bags, | Containers,Bottles,Cans,Buckets etc | ||

Power and Air | Compressed Air | 7bar | ||

Electric Power | 17-25 Kw | |||

Voltage | 380v | 3 Phases | ||

PLC | Siemens | |||

Frequency Converter | Danfoss | |||

Photoelectric Sensor | Sick | |||

Servo Motor | Panasonic | |||

Pneumatic Component | SMC | |||

Low-voltage Apparatus | Schneider | |||

Touch Screen | SchneiderlSiemens | |||

Driving Motor | SEW | |||

SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

Robot Arm | Japanese Brand Robot | Fanuc | Kawasaki | |

German Brand Robot | KUKA | |||

Switzerland Brand Robot | ABB | |||

Main Performance | Speed Capacity | 8s Per Cycle | Adjust according to products and | |

Weight | About 8000kg | |||

Applicable Product | Cartons,Cases,Bags, | Containers,Bottles,Cans,Buckets etc | ||

Power and Air | Compressed Air | 7bar | ||

Electric Power | 17-25 Kw | |||

Voltage | 380v | 3 Phases | ||

PLC | Siemens | |||

Frequency Converter | Danfoss | |||

Photoelectric Sensor | Sick | |||

Servo Motor | Panasonic | |||

Pneumatic Component | SMC | |||

Low-voltage Apparatus | Schneider | |||

Touch Screen | SchneiderlSiemens | |||

Driving Motor | SEW | |||