Automobile Manufacturing Robots

Automobile Manufacturing Robots:

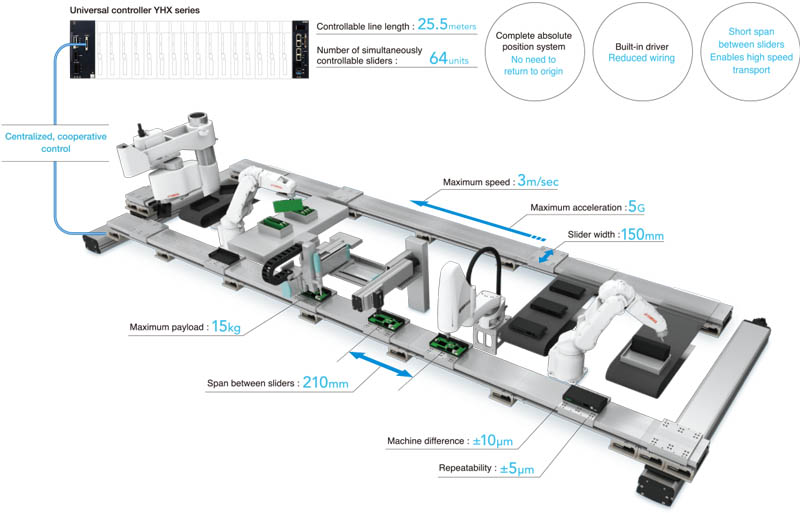

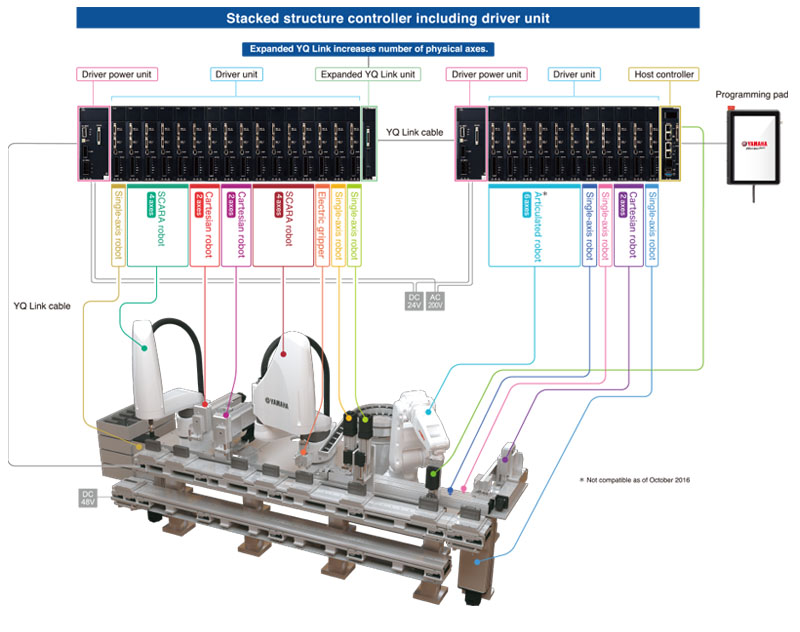

1,Increased production efficiency: Automobile manufacturing robots are programmed to perform tasks with speed and accuracy, resulting in higher production rates. They can work continuously without fatigue, minimizing downtime and maximizing output.

2,Improved product quality: Robots are capable of performing tasks with precision, ensuring consistent quality in the manufacturing process. They eliminate human errors and variations, resulting in uniformity and fewer defects in the final products.

3,Enhanced worker safety: Robots take over hazardous and strenuous tasks, reducing the risk of injuries for human workers. They are equipped with safety features such as sensors and protective barriers, ensuring a safer working environment. This not only protects workers but also results in reduced worker compensation claims and associated costs.

Automobile Manufacturing Robots:

Automobile Manufacturing Robots, such as the Kuka PRC Robots in Architecture, have gained widespread attention due to their numerous advantages. One key aspect is the degree of freedom in robotics, which enables these robots to perform complex tasks with precision. Additionally, these robots contribute to environmental sustainability, as seen in the rising trend of Green Energy Robotics. They are designed to be energy-efficient, reducing energy consumption and carbon emissions. With their advanced capabilities, these robots revolutionize the automobile manufacturing industry, enhancing production efficiency and product quality while ensuring worker safety. As technology continues to advance, we can expect further developments in this field, with a focus on increasing automation and reducing environmental impacts.