Robotics And Automation Engineering

1. The cutting speed is quick—twice as quick as competing items.

2. Extreme cutting accuracy. The system's repeated positioning accuracy is up to 100 um.

3, Can cut a 2 mm diameter circle with no obvious burrs or variations in the cutting effect. One small circle's cutting time can be managed in under two seconds.

4, The manipulator's 2.01-meter-long arm is optional.

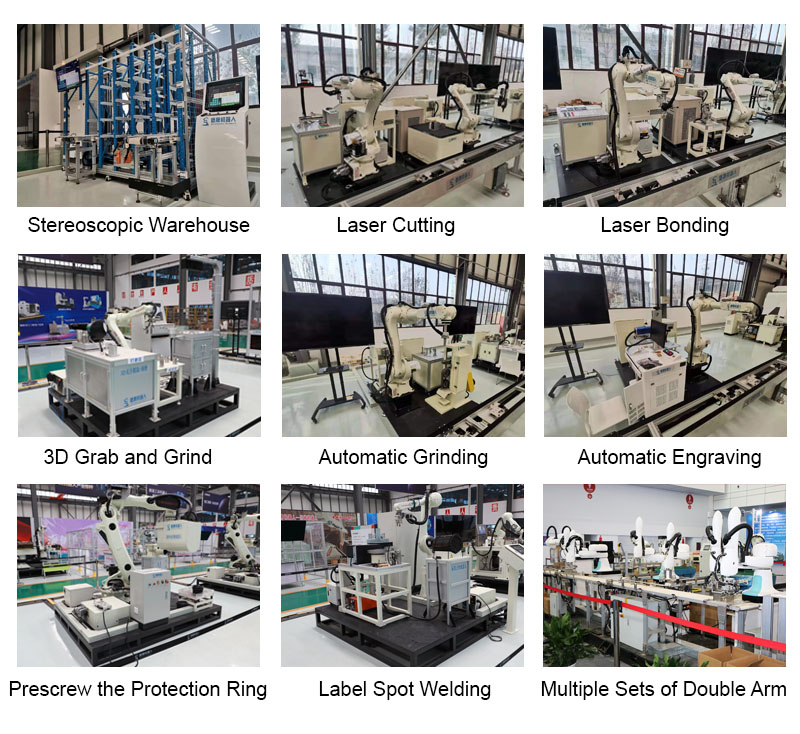

Robotics And Automation Engineering:

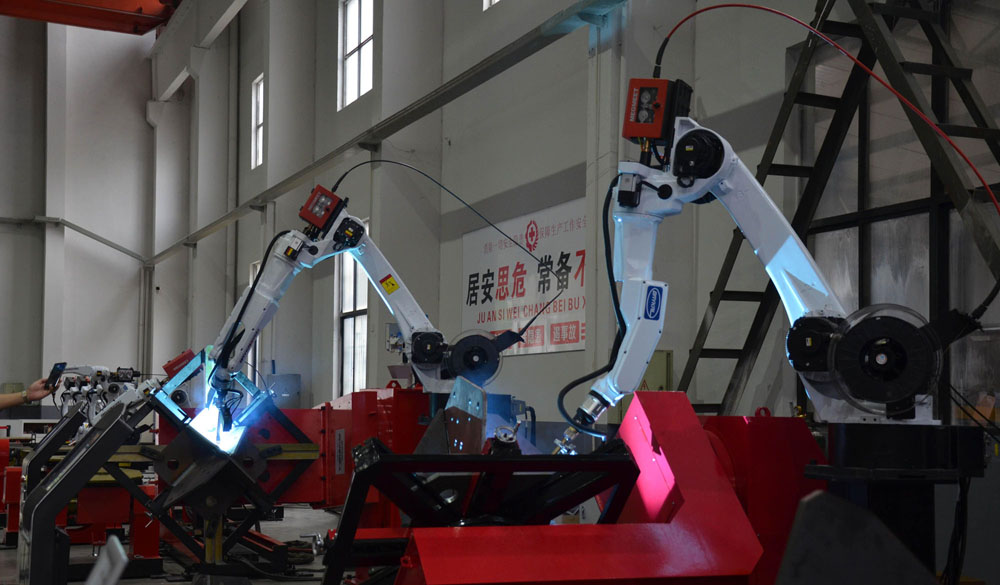

Three-dimensional fiber laser cutting machine,which belongs to the Robotics And Automation Engineering, such as unimate robot, articulated robot,manufacturing robots,is composed of special fiber laser cutting head, high precision capacitive tracking system,fiber laser and industrial robot system, to different thickness of metal plate multi-angle, multi-azimuth flexible cutting equipment. 3D robot laser cutting machine equipment is widely used in metal processing, machinery manufacturing and auto parts manufacturing and other 3D workpiece processing demand production.

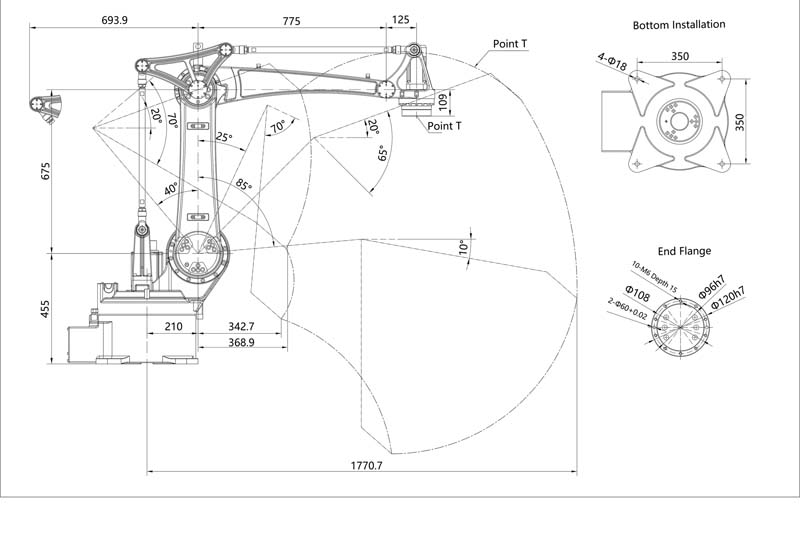

Parameter:

Name | Robotics And Automation Engineering | |||||

Type | Vertical joint 6 degrees | |||||

The main purpose | Weld | |||||

Specification | BR20iA-18 | |||||

Max load weight | 6KG | |||||

Position repeatability | 0.08mm | |||||

Battery capacity | 3KVA | |||||

Body weight | 200KG | |||||

Maximum reach | 1945mm | |||||

Conditions | 0-45°C, 20-80%RH (no condensation) | |||||

Protection class | Equivalent to IP65 | |||||

Installation | Ground, hoisting side mounting | |||||

basic axis | J1 | ±175° |

Max speed | basic axis | J1 | 172.1°/s |

J2 | +85° -150° | J2 | 138.8°/s | |||

J3 | +80° | J3 | 259.3°/s | |||

arm axis | J4 | ±150° | arm axis | J4 | 294.1°/s | |

J5 | +130° -105° | J5 | 294.1°/s | |||

J6 | ±220° | J6 | 426.7°/s | |||

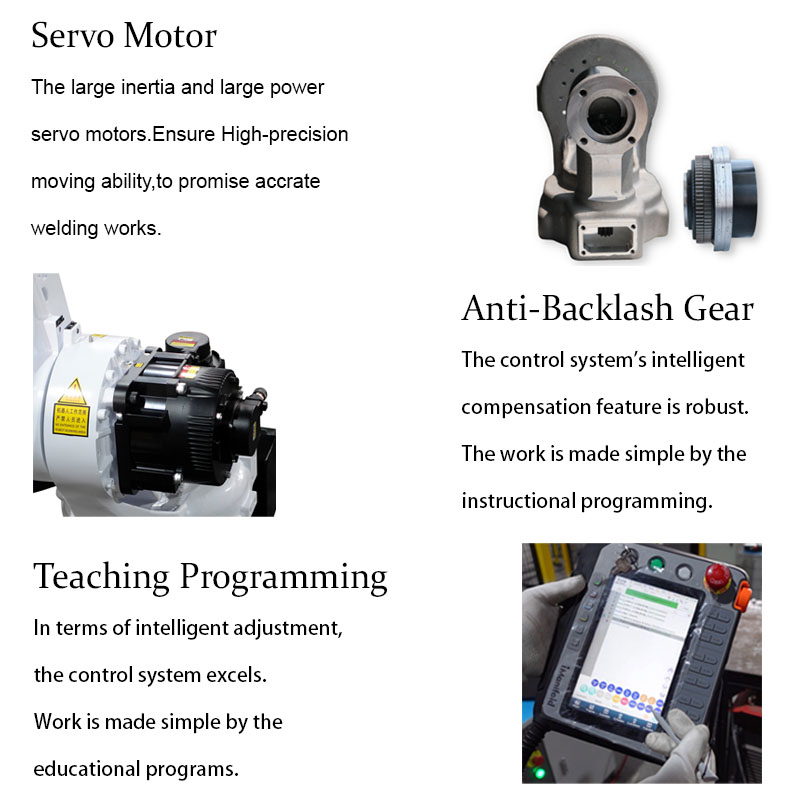

Details:

Features:

Its tremendous degree of flexibility is mostly seen in two ways:

1, Strong adaptability to the material, laser cutting machine through the numerical control program can basically cut any plate.

2, The processing path is controlled by the program, if the processing object changes, you only need to modify the program, which is particularly obvious when the parts are trimming and cutting holes.

Applications:

It is widely used in automobile and motorcycle industry, including electric bicycle and helmet field: for example, cutting hole, trimming edge of body covering parts, cutting steering wheel hole, body windscreen, roof cover bracket hole, airbag parts, hydraulic forming parts, etc. Three-dimensional laser cutting is also very useful in the processing of body assembly, such as open luggage rack with fixed hole, top cover slide rail hole, antenna installation hole, modify wheel fender shape, etc.

After-Sales Service:

1,12 months for main parts(engine,axle,body and beam,etc).

2,24/7 technical support through phone, Whatsapp, or email.

3,Lifelong Parts Supports.

4,Engineer available service oversea.

Packing & Shipping:

We typically use bulk cargo, flat rack, containers, and Roro ships for shipping.

Depending on how many things there are, we will arrange the most affordable form of transportation.

Before shipping, all trailers will receive a wax polishing.Every sale we close aims to have a 100% client satisfaction rate.

Delivery period: 10–20 working days following confirmation of payment receipt (depending on actual quantity).

Packing:Standard export packaging is available, as is custom packing upon request.

Professional goods shipping forwarder.

Production Process:

Certifications:

Customer Visit:

Cooperation Partner:

Exhibition:

More Products: