Carbon Block Cleaning System

Advantages of Carbon Block Cleaning System:

1,Enhanced Efficiency: The Carbon Block Cleaning System's advanced automation technology allows for enhanced efficiency in the cleaning of carbon blocks. The use of automated equipment improves the speed and accuracy of the cleaning process, reducing the time required for manual cleaning while maximizing output.

2,Improved Quality: The automated process of the Carbon Block Cleaning System ensures consistent and thorough cleaning of carbon blocks, leading to improved product quality. By ensuring that carbon blocks are free from residue and contaminants, the system contributes to the production of high-quality carbon products.

3,Enhanced Safety: The use of automated equipment in the Carbon Block Cleaning System promotes a safer working environment. The system's automated cleaning process reduces the need for human intervention, reducing the potential for workplace injuries while also improving throughput.

Carbon Block Cleaning System:

Robotics and automation engineering has revolutionized the way that we work and manufacture products. Industrial Robot applications have played a significant role in the success of many companies, enhancing productivity and consistency in manufacturing processes. One of the most important developments in industrial robots was the creation of the Unimate Robot by George Devol in 1956. This robot was the first Industrial robot ever produced, and it paved the way for modern automation techniques and revolutionized the industry. Today, industrial robots are used in a wide range of applications, from assembly line production to welding and material handling. Robotics and automation engineering continue to advance, with new technologies continuously being developed to make manufacturing processes more efficient, safe and sustainable.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

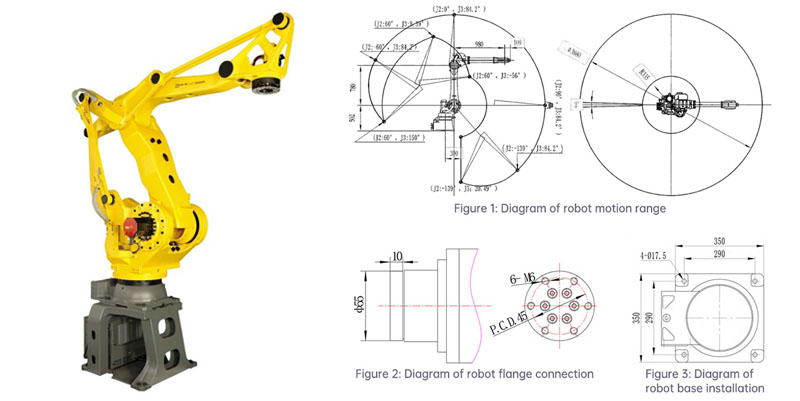

DIMENSIONAL DRAWINGS:

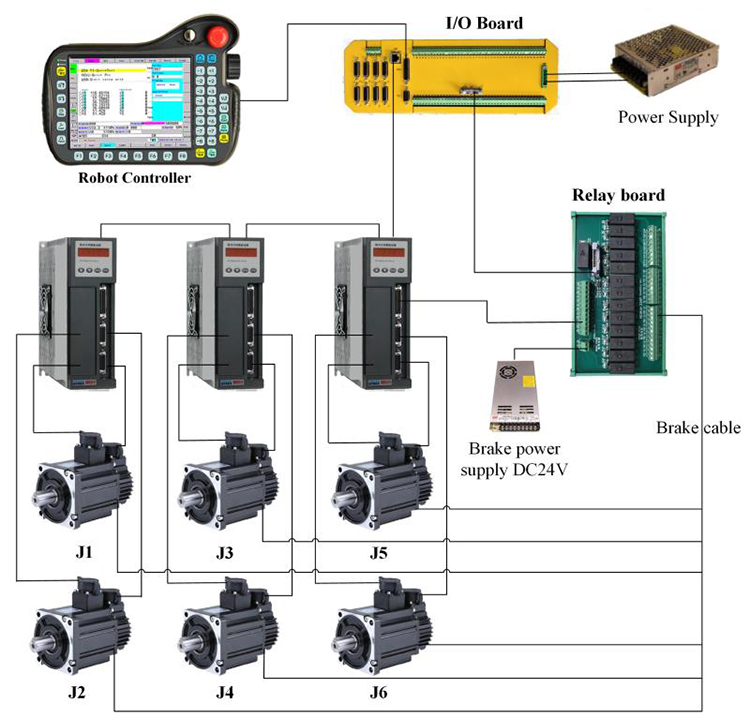

ROBOT CONTROLSYSTEM:

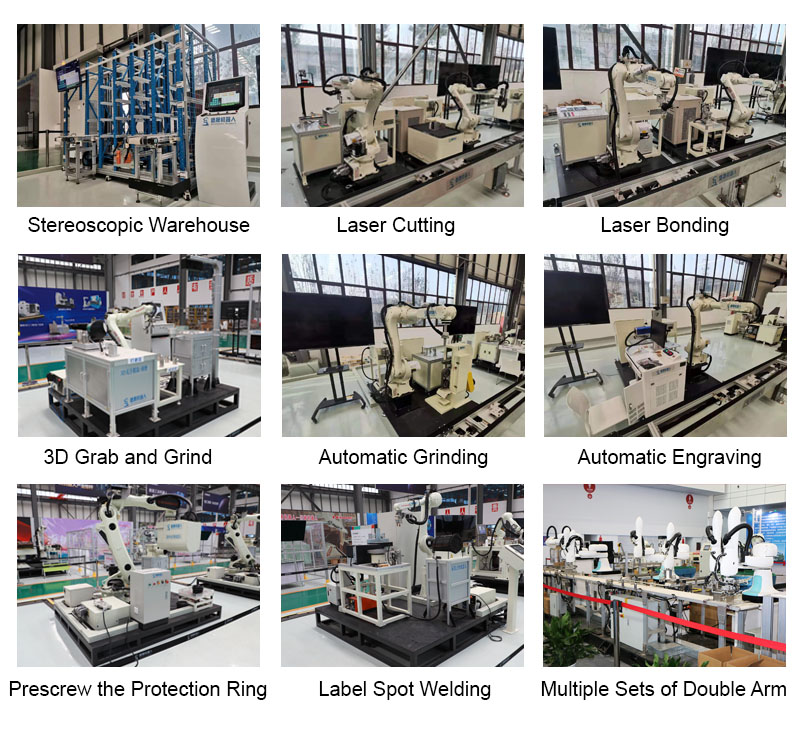

APPLICATIONS:

1,Water filtration systems: Carbon block cleaning system can be used in water filtration systems, where the carbon blocks are used to remove impurities and contaminants from the water. Over time, the carbon may become clogged or fouled, reducing its effectiveness. The carbon block cleaning system helps to maintain the performance of the filters and ensure consistent water quality.

2,Industrial processes: Carbon block cleaning system can be used in industrial processes that involve the use of activated carbon. For example, in the pharmaceutical industry, activated carbon is used to purify drugs and remove impurities. The carbon blocks may become saturated or contaminated and require cleaning to maintain their effectiveness.

3,Environmental remediation: The Carbon block cleaning system can be used in environmental remediation efforts where activated carbon is used to remove pollutants and contaminants from soil or water. The activated carbon may become fouled and require cleaning to maintain its ability to remove pollutants. The cleaning system helps to maintain the performance of the remediation process and ensure that the contaminants are being effectively removed from the environment.

FEATURES:

1,High efficiency: The Carbon Block Cleaning System is designed to clean carbon blocks quickly and efficiently, allowing them to be brought back into service as soon as possible. The cleaning process can take as little as a few minutes, allowing companies to minimize downtime and maximize productivity.

2,Cost-effective: The use of Carbon Block Cleaning System is more cost-effective than replacing carbon blocks entirely. The cleaning process can extend the lifespan of the blocks, reducing the need for frequent replacements and minimizing maintenance costs.

3,Environmentally friendly: The Carbon Block Cleaning System is an environmentally friendly solution that reduces waste and reduces the carbon footprint of companies. Instead of disposing of used carbon blocks and replacing them with new ones, the cleaning system allows companies to reuse their existing blocks, reducing the amount of waste generated and reducing the need for new materials.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: