Advanced Robot Control Electronics

Advantages of Advanced Robot Control Electronics:

1,Enhanced Production Efficiency: Advanced robot control electronics can significantly improve production efficiency, reduce human error, and streamline manufacturing processes in the automobile manufacturing industry, leading to increased productivity and profitability.

2,Improved Quality Control: With advanced robot control electronics, it is easier to perform precise measurements and perform visual inspections, ensuring consistent product quality and reducing defects that could impact safety or reliability.

3,Reduced Costs: Implementing advanced robot control electronics can help cut costs by reducing the need for human labor, enhancing cost-efficiency and contributing towards better cost control.

4,Faster Time-to-Market: LS Automotive Technologies can leverage advanced robot control electronics to accelerate development cycles for new models and technologies, meeting industry demands and customer expectations with faster time-to-market.

Advanced Robot Control Electronics:

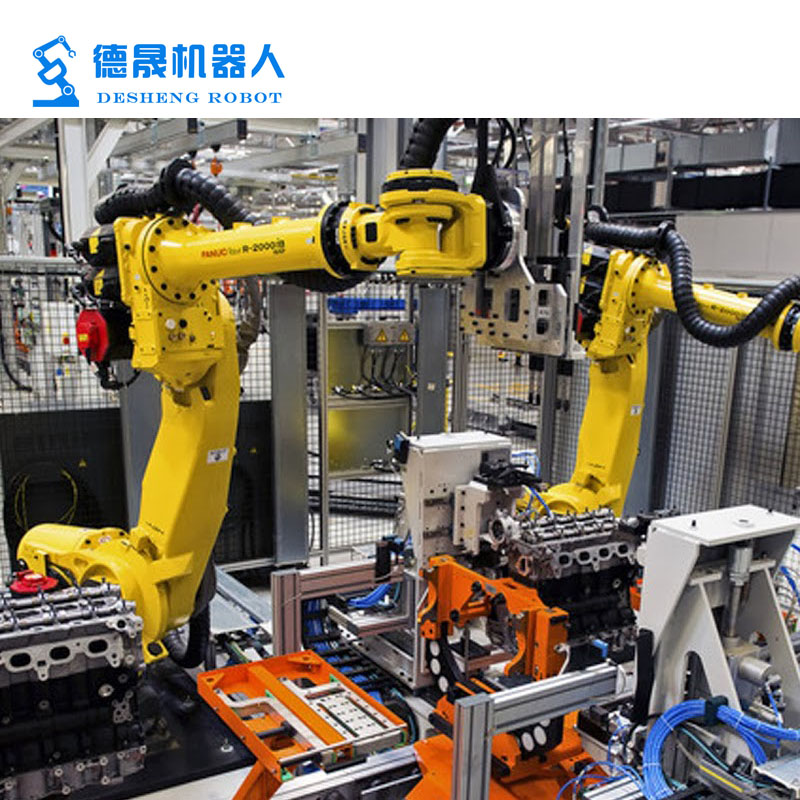

The implementation of Advanced Robot Control Electronics has become increasingly important in the Automobile Manufacturing Industry. LS Automotive Technologies is embracing this trend with open arms, utilizing advanced robot control electronics to improve production efficiency, reduce costs and accelerate the development cycles for new models and technologies. Meanwhile, British Car Companies are also adopting this technology to enhance their market position and improve manufacturing efficiency, producing innovative, high-quality vehicles at competitive prices. With the ability to streamline manufacturing processes, reduce human error, and perform precise measurements, advanced robot control electronics will continue to play an essential role in the evolution of the automotive industry.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

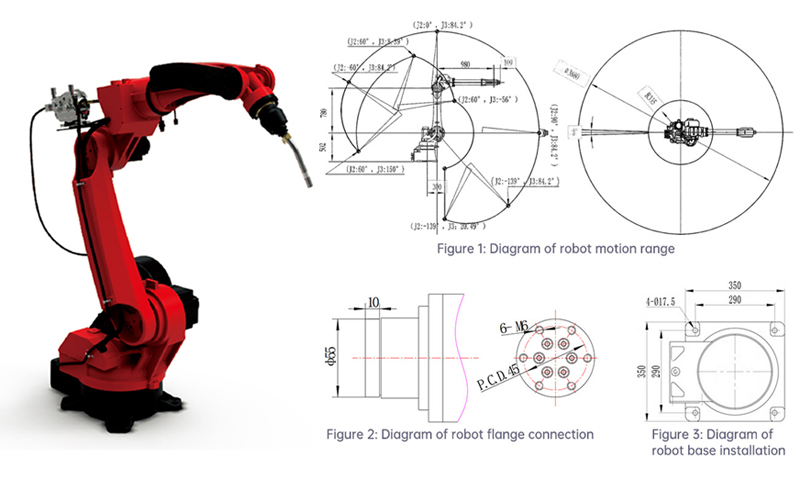

DIMENSIONAL DRAWINGS:

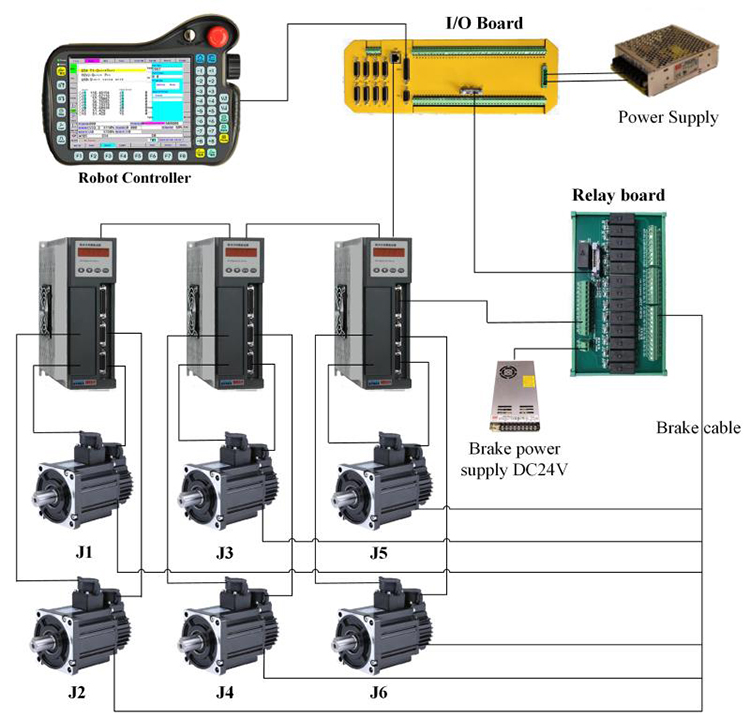

ROBOT CONTROLSYSTEM:

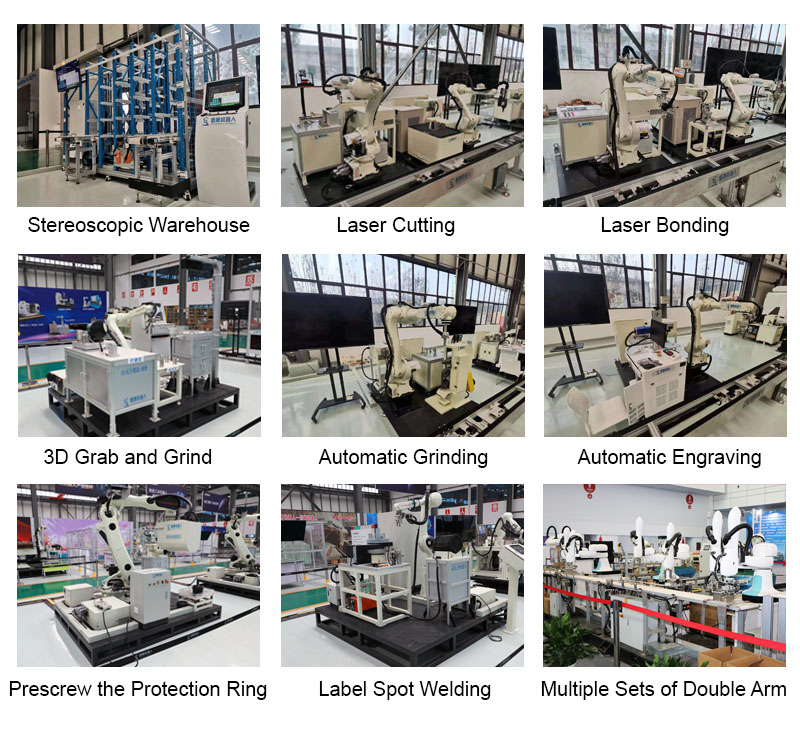

APPLICATIONS:

1,Manufacturing: in manufacturing, palletizing robots may be used to stack and flow heavy factors, completed merchandise and raw materials. in the vehicle industry, as an instance, they might region frames, engines, and different crucial additives to hurry up production and increase manufacturing performance.

2,Logistics and warehousing: within the logistics and warehousing industry, palletizing robots may be used to package deal, sort and arrange goods. for example, gadgets may be stacked through the usage of robots and moved to the proper vicinity steady with distinctive orders. this allows logistics corporations and storage centers to manipulate and pass massive volumes of goods more correctly and reduce human useful aid fees.

3,Meals and beverage business enterprise: palletizing robots are typically used in the food and beverage industry to stack and pass meals cans, bottles, packing containers and baggage. the robotic can quick and successfully p.c. those merchandise into boxes or pallets. this computerized approach can lessen the amount of exertions for employees, thereby developing manufacturing overall performance and decreasing human mistakes.

FEATURES:

1,Immoderate precision: palletizing robot may be operated in keeping with very particular preset parameters, as a result guaranteeing a excessive degree of accuracy in stacking and arranging items. the robotic's immoderate-precision operation nearly eliminates stacking problems because of human mistakes.

2,Programmable: palletizing robots for cargo stacking are programmable, because of this that they're capable of customise their manner of operation to in shape different sorts and sizes of shipment. this makes them more flexible and able to meet distinct stacking goals in a variety of industries.

3,Excessive protection: palletizing robots carry out with a excessive diploma of safety. through using advanced sensor era and tracking systems, the robot is able to avoid collision with any transferring individual or different barriers, consequently ensuring a high level of protection throughout use.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: