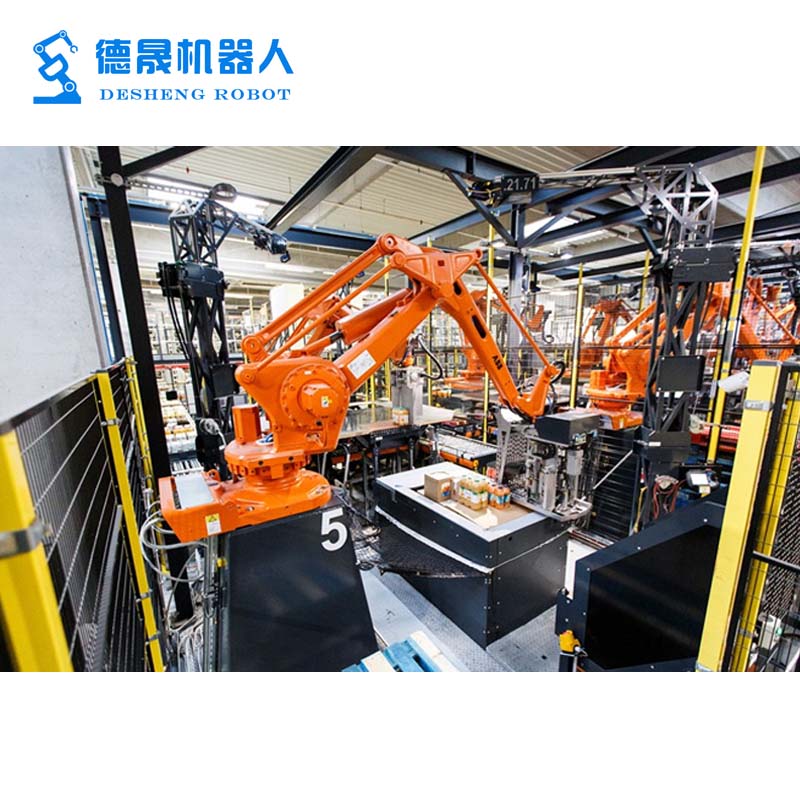

Unimate Robot Automation Assembly

Advantages of Unimate Robot Automation Assembly:

1. Improve production efficiency: Robots can work continuously without rest or downtime, which greatly increases productivity and reduces manual error rate.

2. Improve product quality: The working precision of the robot is high, and its program can be repeated, so it can produce high-quality products stably.

3. Improve the working environment: Robots can complete repetitive, dangerous or high-risk tasks, thus reducing human injuries and potential dangers.

4. Cost reduction: Robots can efficiently complete simple and complex tasks, improve work efficiency, reduce costs and improve profits.

5. Increase productivity: Robots can complete multiple production steps at the same time, thus increasing productivity, reducing production cycle and improving efficiency.

Unimate Robot Automation Assembly:

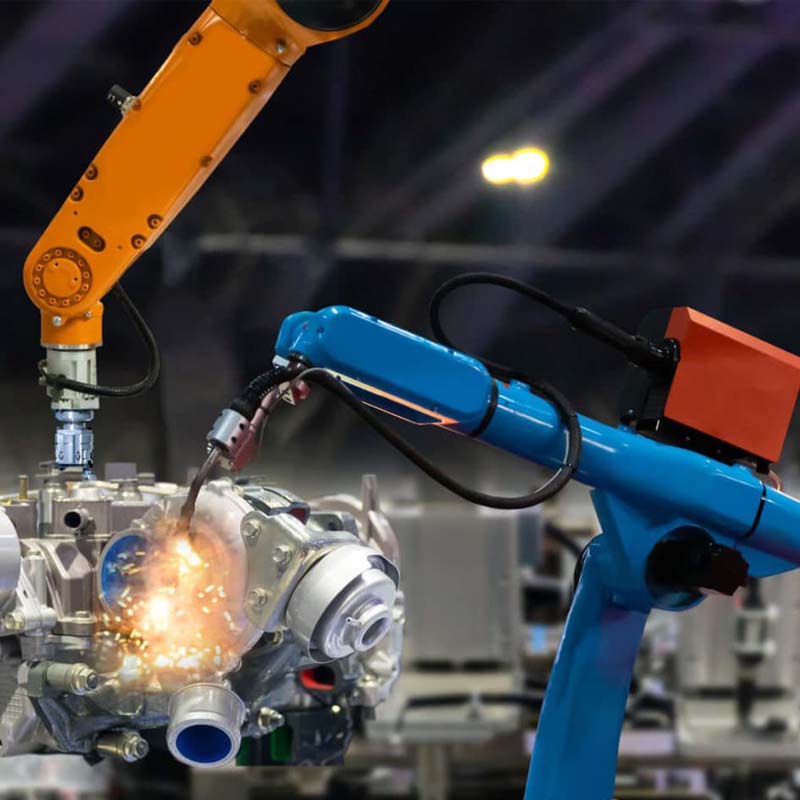

Unimate Robot Automation Assembly, Stick Shielded Metal Arc Welding, ASME Section 9 Brazing Procedures, and Victor Welding Cutting Torches are all important tools and processes used in modern manufacturing and fabrication. The Unimate Robot Automation Assembly is a versatile tool that can help streamline the manufacturing process, resulting in higher efficiency and better product quality. Stick Shielded Metal Arc Welding, on the other hand, is a welding method that requires the use of a stick electrode to create an electrical arc that melts the metal and fills the joint. This method is known for producing exceptionally strong welds, making it a popular choice for heavy-duty industrial applications. ASME Section 9 Brazing Procedures are vital to ensuring the quality of welded joints in piping and pressure vessels. Finally, Victor Welding Cutting Torches allow for precise cutting of metal and are an essential tool in many fabrication applications. Together, these tools and processes make modern manufacturing possible and contribute to a wide range of industries.

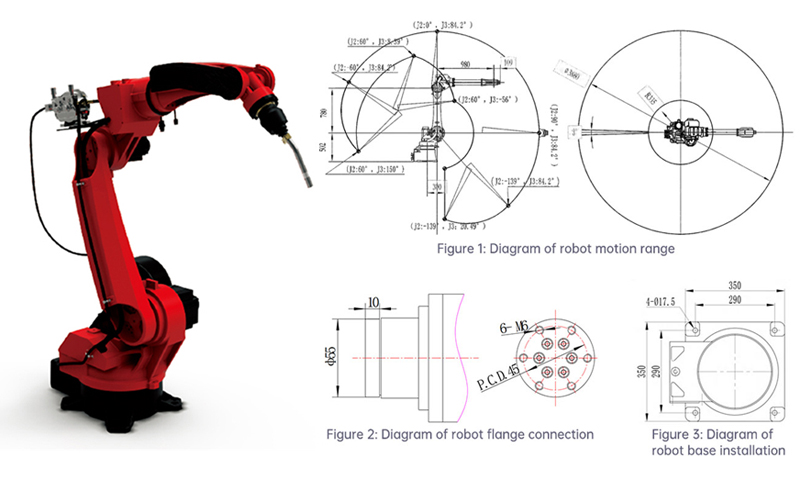

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

DIMENSIONAL DRAWINGS:

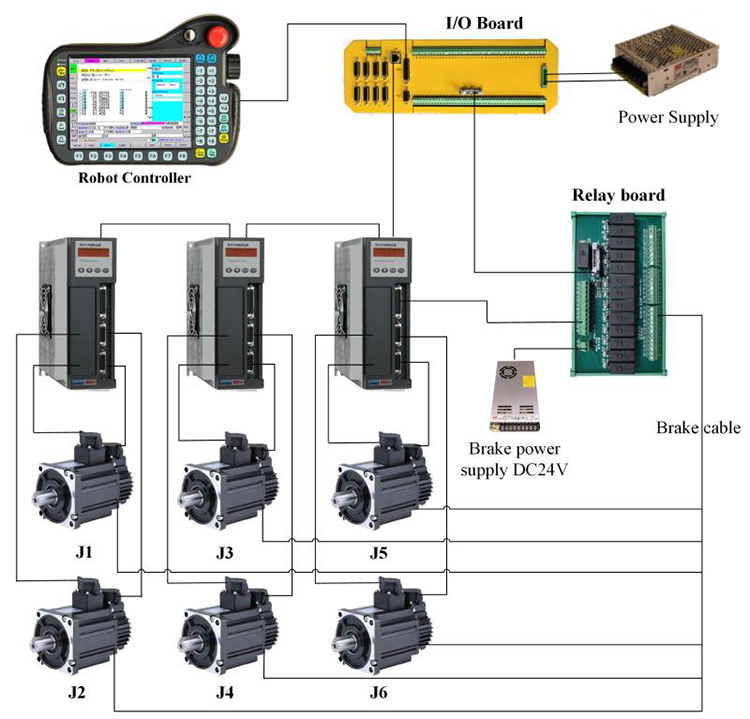

ROBOT CONTROLSYSTEM:

ADVANTAGE:

1,Unfastened Saving

May be operated 24 hours, effec-tively keep difficult paintings prices. in additionthe use of enterprise manipulator operation mode, computerized assembly line to save the internet page, sothat the complete plant planning more compact.

2,Immoderate Manufacturing General Overall Performance

Manipulator manufacturing of a producttime is regular within the identical manufacturing cycle, the output is normal product yield is excessive, immoderate manufacturing blessings.

3,Excessive Balance

Manufacturing operation, immoderate precision,immoderate stability,can assure person-nel,in choice to manual unstable operations.

4,Splendid Software Program Range

It's miles suitable for hardware device-ing, car add-ons,furni-ture add-ons, heating pipewelding embedded additives, and so on.

FEATRUES:

1,Help as hundreds as 12 axis control, realizes the control of out of doors axes (visiting axes and positioner).

2,Structural optimization set of guidelines suitable for the body manipulate of numerous kinds of shape.

3,Open shape for synchronization of global era and extension of abilties.

4,Software program software program abilities facilitate common revel in manage. approach skills make programming clean.

5,Modular setting of features appropriate for numerous applications. safety module guarantees comfy manufacturing of the robots.

6,Appropriate for a couple of increments; absolute servo. superior laptop bus connection guarantees reliability and practicability.

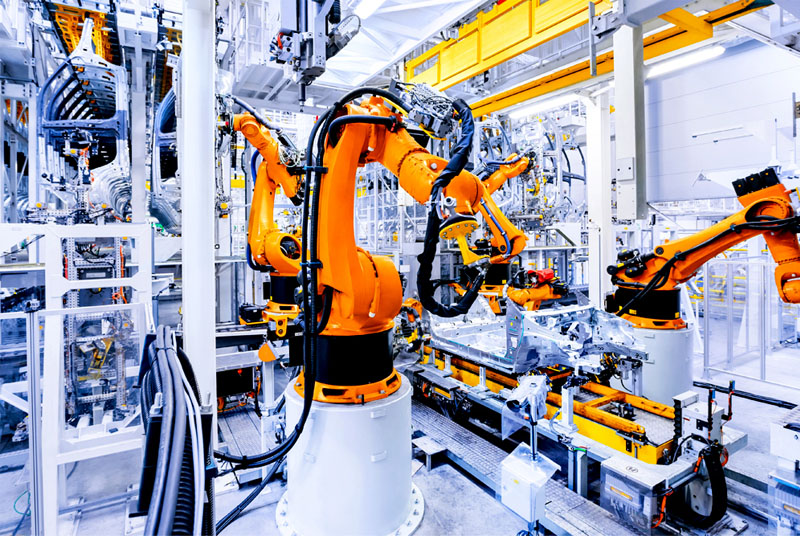

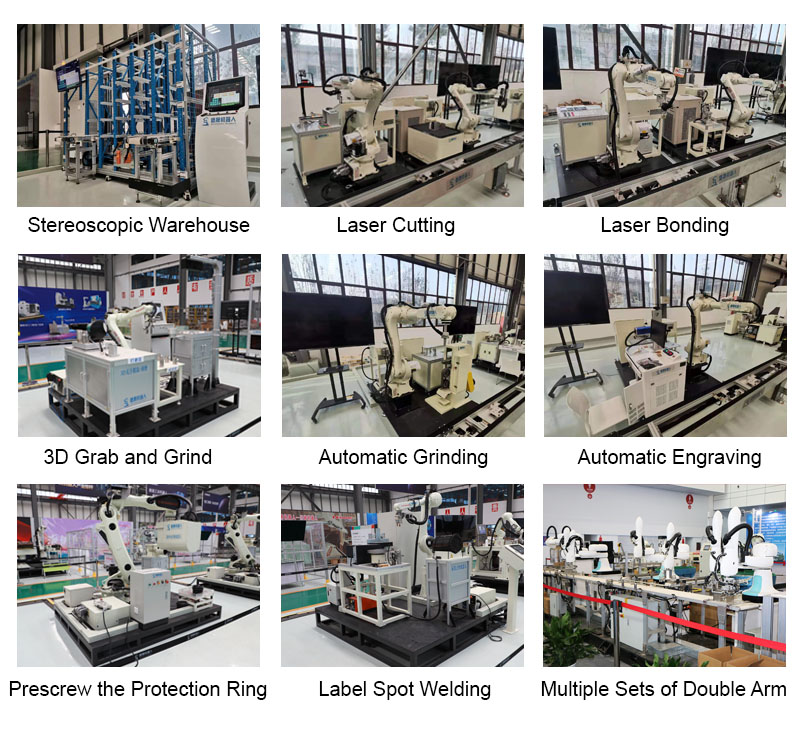

APPLICATIONS:

1, Production line, and vehicle factors production. the pocket ebook area requires coordination some of the positioner and welding robotic to gain automated welding, with seamless motion that meets the welding tune, speed, and gun feature necessities.

2, The welding robot manufacturing reduces manpower costs and improves ordinary performance through connecting workpiece conveying traces to shape a manufacturing line.

3, Vehicle elements manufacturing substantially advantages from welding robots, mainly inside the vehicle chassis welding tool, in which welding robotic modified in advance operations, improving every welding exquisite and operation time.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: