Carbon Block Task Scheduling Robots

Advantages of Carbon Block Task Scheduling Robots:

1,Increased Efficiency: Carbon Block Task Scheduling Robots' advanced automation technology allows for increased efficiency in carbon block production. The robots use advanced algorithms to optimize task scheduling, reducing the time required for manual labor while improving throughput.

2,Enhanced Precision and Accuracy: The high-precision sensors and advanced programming of the Carbon Block Task Scheduling Robots ensure accurate measurement and positioning of carbon blocks, leading to improved product quality. By optimizing the scheduling process, the robots can further enhance precision by minimizing errors and waste.

3,Reduced Costs: The use of automation technology in Carbon Block Task Scheduling Robots reduces the cost of production. The robots require fewer resources than manual labor, leading to reduced operational costs, and improved profitability.

Carbon Block Task Scheduling Robots:

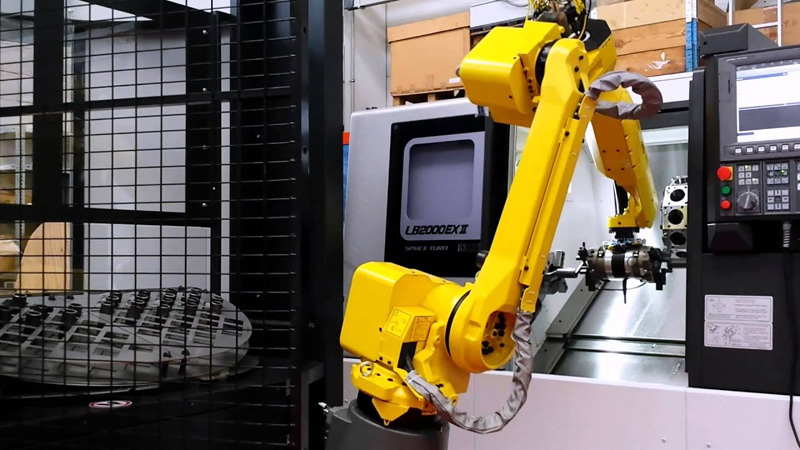

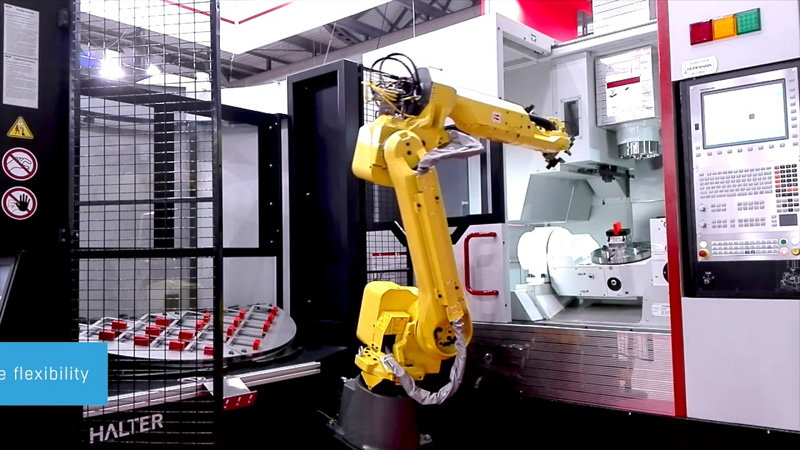

The use of robotics technology in carbon block manufacturing has continued to revolutionize manufacturing processes, with Carbon Block Task Scheduling Robots being a prime example. These robots use advanced scheduling algorithms and high-precision sensors to optimize carbon block production, enhancing efficiency, and reducing operational costs.

The implementation of manufacturing robots in industry is not exclusive to carbon block manufacturing, as Japanese robotics companies continue to revolutionize the manufacturing industry. These companies have developed innovative technology in material handling robots, increasing production speed, reducing waste and enhancing safety in the workplace.

Overall, the implementation of Carbon Block Task Scheduling Robots and other manufacturing robots in different industries indicates the growing acceptance of robotics technology. Improvements in robotics technology will continue to transform various sectors, with exciting advancements expected in the coming years. As the technology advances, the use of automation in manufacturing processes is expected to become even more advanced and sophisticated.

PARAMETERS:

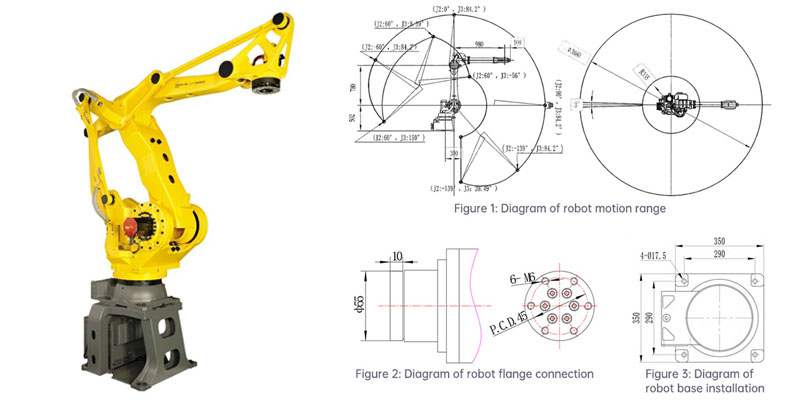

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

DIMENSIONAL DRAWINGS:

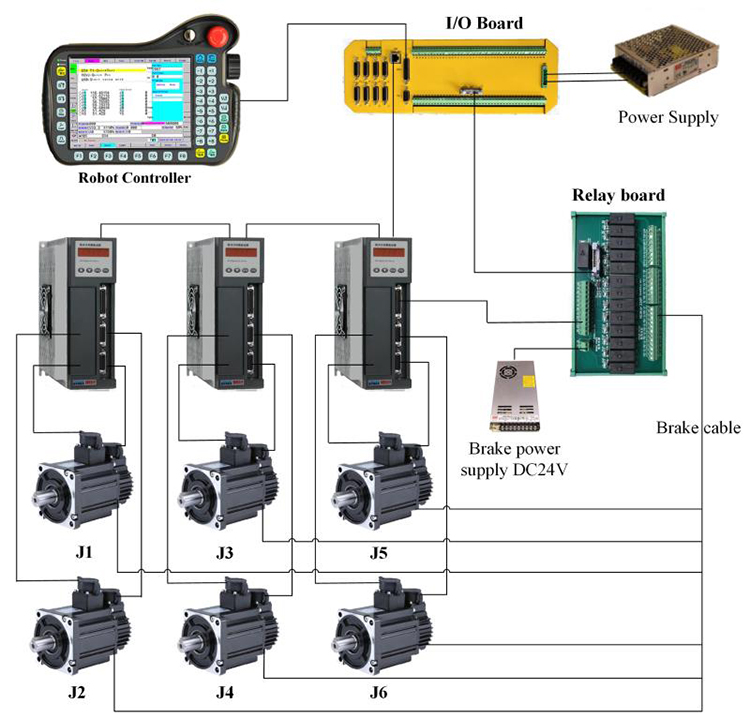

ROBOT CONTROLSYSTEM:

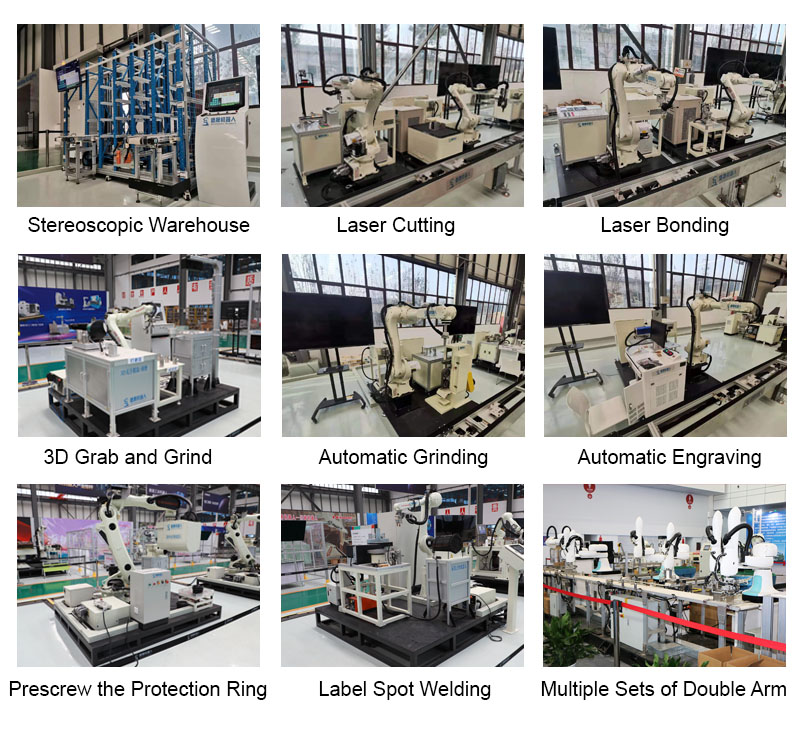

APPLICATIONS:

1,Mining industry: Carbon Block Task Scheduling Robots can be used in the mining industry to schedule the deployment of vehicles and machinery used in the mining process. The robots can be programmed to optimize the allocation of resources, ensuring that carbon blocks are used effectively and efficiently in the mining process.

2,Energy industry: Carbon Block Task Scheduling Robots can also be used in the energy industry to schedule the deployment of carbon capture equipment. The robots can be programmed to schedule the collection and allocation of carbon blocks from different sources, ensuring that the equipment is always available when needed.

3,Waste management: Carbon Block Task Scheduling Robots can be used in waste management operations where carbon blocks are used to treat or remove pollutants from wastewater or hazardous waste streams. The robots can be programmed to schedule the allocation of carbon blocks, optimizing the use of resources and reducing waste.

FEATURES:

1,Efficient resource allocation: Carbon Block Task Scheduling Robots are designed to optimize the allocation of carbon blocks and other resources. This helps reduce waste, improve efficiency, and ensure that tasks are completed on time and within budget.

2,Real-time monitoring: The robots are equipped with sensors and monitoring devices that allow them to collect data in real-time. This data can be used to optimize schedules and adjust processes as needed, ensuring that resources are being used effectively and efficiently.

3,Increased productivity: Carbon Block Task Scheduling Robots can automate the task scheduling process, freeing up human workers to focus on other tasks. This helps improve productivity and can lead to cost savings for companies.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: