Automated Robotics In Logistics

Advantages of Automated Robotics In Logistics:

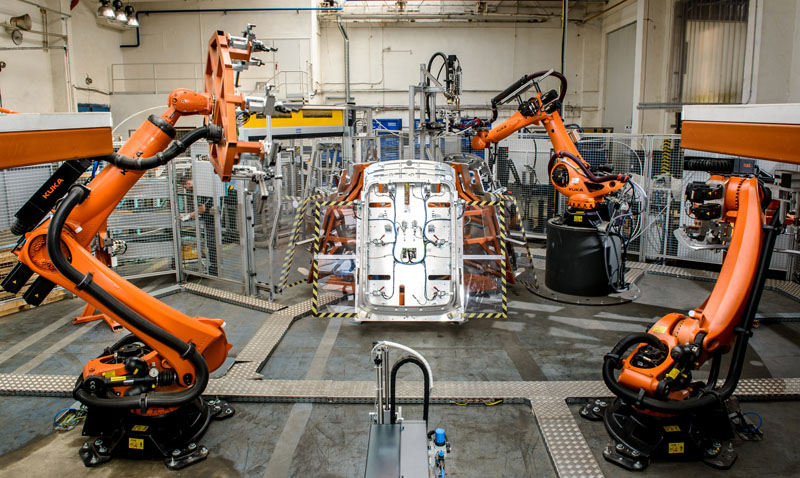

1,Increased Efficiency: Automated robots in logistics, such as auto assembly line robots, can increase efficiency by reducing the time and effort required for manual tasks. They can handle repetitive tasks more quickly and accurately, resulting in faster and more efficient operations. Automation assembly line product is an example of how automated robotics can increase efficiency in the logistics industry.

2,Improved Accuracy: With automated robotics, the chances of human error and mistakes are eliminated. This means that logistics companies can expect more accuracy in their operations, which can reduce costs, minimize downtime, and improve overall productivity. Automated assembly line example shows how automated robotics can improve accuracy in the logistics industry.

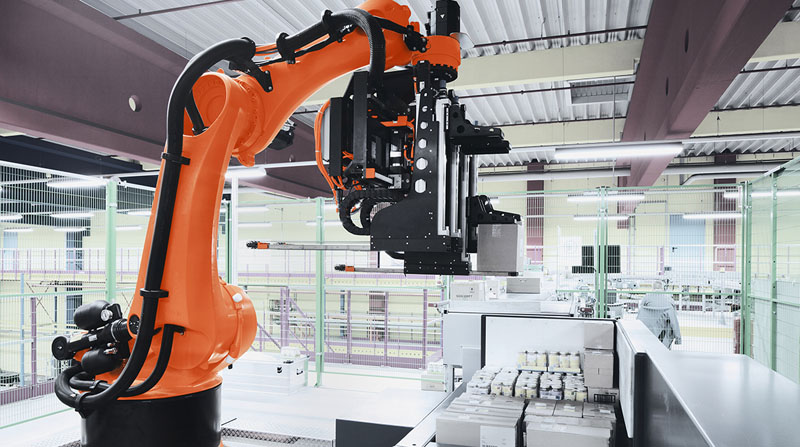

3,Enhanced Safety: Automated robots can handle the most dangerous and risky tasks, eliminating the risk of injury or harm to human workers. This can improve the safety and well-being of workers, as well as reduce insurance and liability costs for logistics companies. Automation assembly line product and automated assembly line example are just some examples of how automated robotics can enhance safety in the logistics industry.

Automated Robotics In Logistics:

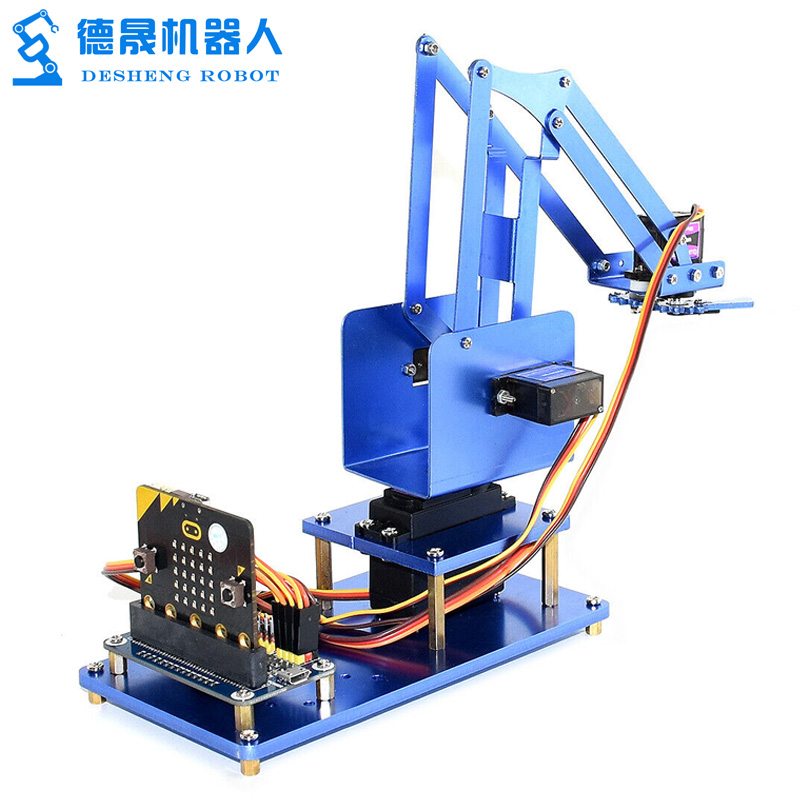

Automated robotics in logistics have made a significant impact in streamlining operations and optimizing efficiency in the supply chain industry. With the development of sophisticated robots and specialized software, logistics companies can now automate repetitive tasks such as picking, packing, and sorting. This ensures faster processing times, fewer errors, and a reduction in labor costs.

Auto assembly line robots are commonly used in the automotive manufacturing industry. These robots can perform tasks such as welding, painting, and assembly with precision and speed that is unmatched by human workers. Not only do these robots improve production efficiency, but they also enhance safety by taking on dangerous tasks.

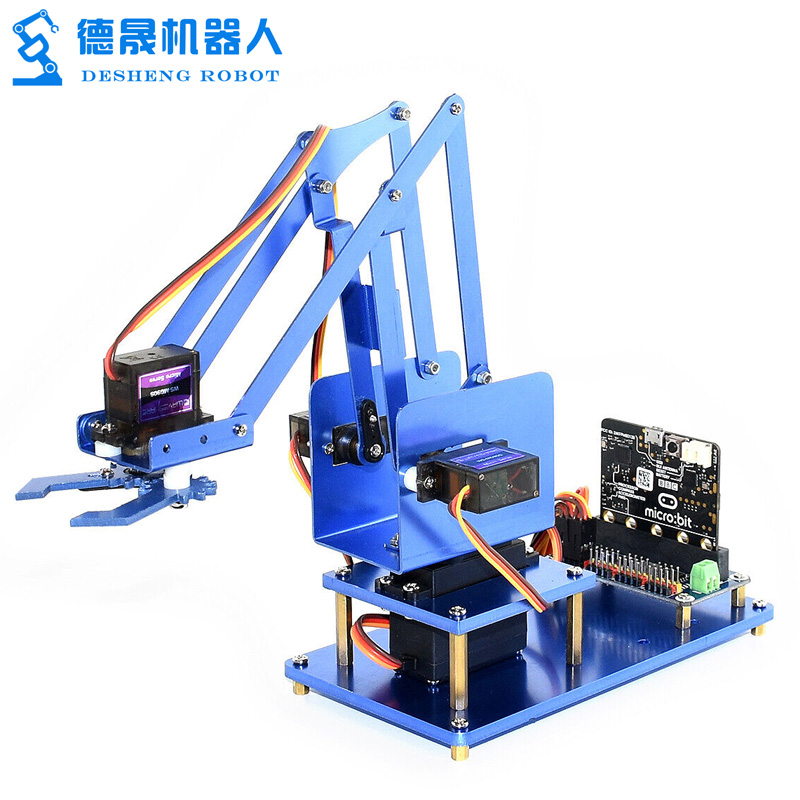

An excellent example of an automated assembly line is the production of smartphones. Smartphones involve the assembly of a large number of small components, which can be labor-intensive and time-consuming. Automation of this process has led to faster production times and reduced labor costs.

The benefits of automation in the assembly line are numerous, including increased productivity, improved quality control, and cost savings. With the use of automation, companies can increase production output while reducing the likelihood of human error. With continued advancements in technology, automation is likely to become even more prevalent in the assembly line and logistics industries.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

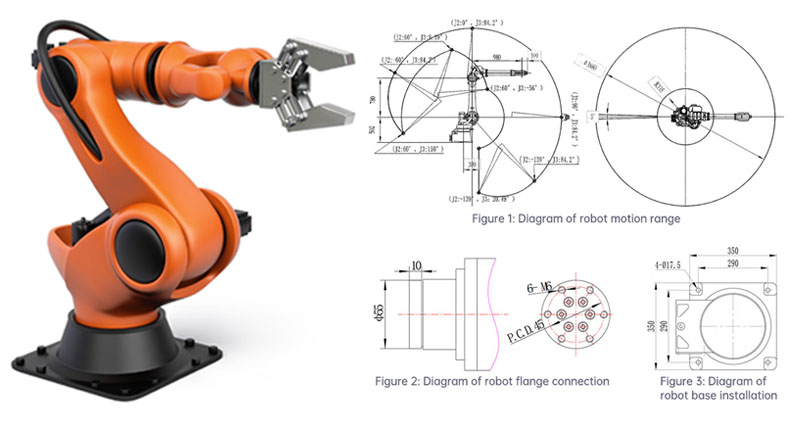

DIMENSIONAL DRAWINGS:

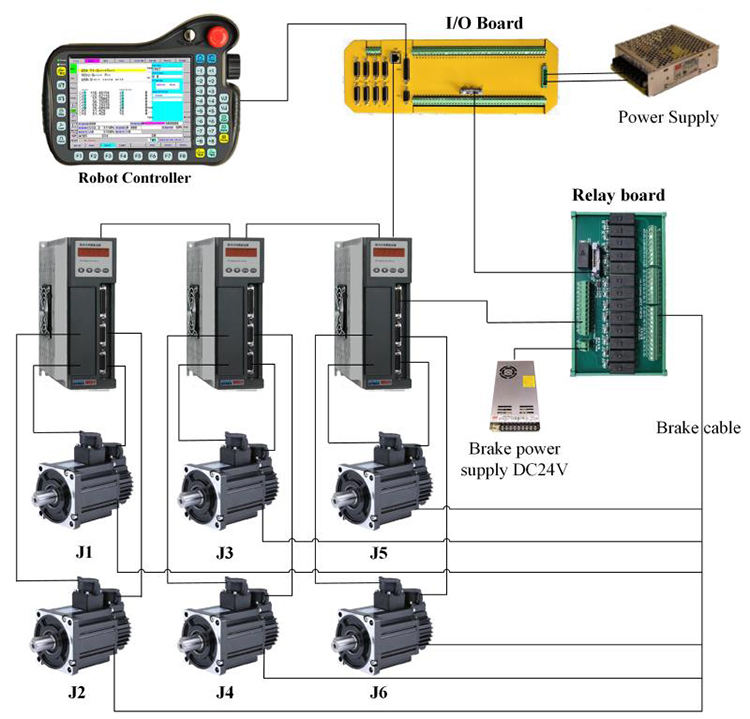

ROBOT CONTROLSYSTEM:

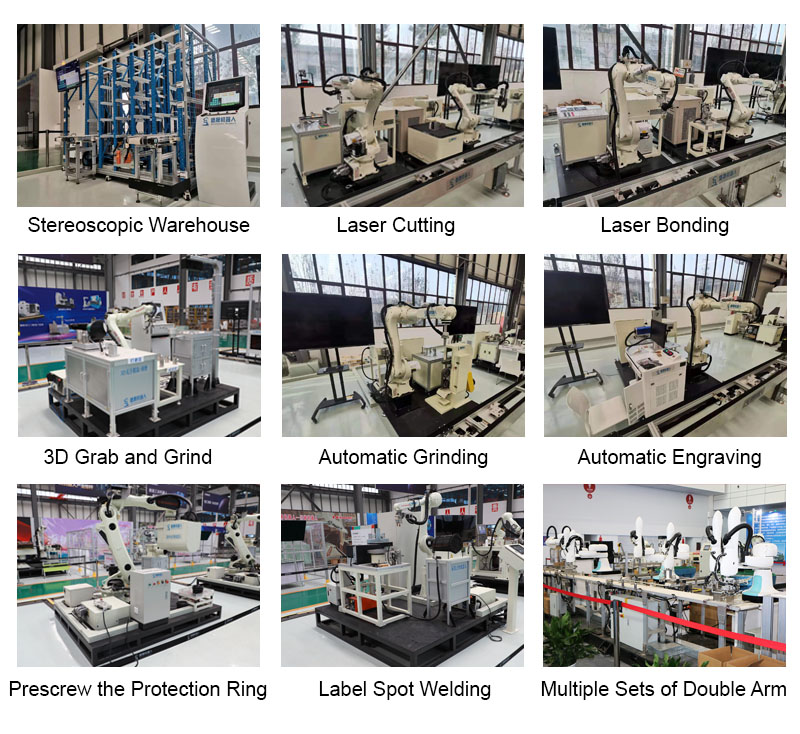

APPLICATIONS:

1,Picking and Packing: Automated robotics in logistics can be used to automate the picking and packing process in warehouses. This involves using robots to move around the warehouse and pick items from shelves, and then pack them into boxes or containers for shipment.

2,Inventory Management: Automated robotics in logistics can also be used to manage inventory levels in warehouses. This involves using robots equipped with scanners to track inventory levels, monitor expiration dates, and manage stock rotation to ensure optimal use of space.

3,Transportation: Automated robotics in logistics can be used to transport goods within a warehouse or between warehouses. This involves using automated guided vehicles (AGVs) to move goods around, reducing the need for human intervention and providing a more efficient and reliable transport system.

FEATURES:

1,Increased Efficiency: Automated robotics in logistics use advanced technologies such as machine learning and artificial intelligence to optimize warehouse operations. This leads to faster processing times, greater accuracy, and reduced labor costs.

2,Flexibility: Automated robotics in logistics can be customized to fit specific warehouse requirements. Robots can be programmed to perform a variety of tasks, making it easier to adapt to changes in inventory levels and demand.

3,Improved Safety: Automated robotics in logistics takes on many of the dangerous and strenuous tasks involved in warehouse operations, reducing the risk of accidents and injuries to human workers. Furthermore, with the ability to monitor and analyze events, automated systems can detect safety hazards at an early stage and take measures to prevent accidents.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: