Carbon Block Task Allocation Robots

Advantages of Carbon Block Task Allocation Robots:

1,Increased Efficiency: Carbon Block Task Allocation Robots' advanced automation technology allows for increased efficiency in carbon block production. The use of robots for task allocation streamlines the production process, reducing the time and resources required for manual labor while improving throughput.

2,Enhanced Precision and Accuracy: The high-precision sensors and advanced programming of the Carbon Block Task Allocation Robots ensure accurate measurement and positioning of carbon blocks, leading to improved product quality. The robots can also detect defects and inconsistencies, allowing for prompt adjustments in the production process.

3,Improved Safety: The innovative use of robots in the Carbon Block Task Allocation system promotes a safer work environment. The robots can perform tasks that would otherwise require human intervention, reducing the potential risks associated with manual production processes.

Carbon Block Task Allocation Robots:

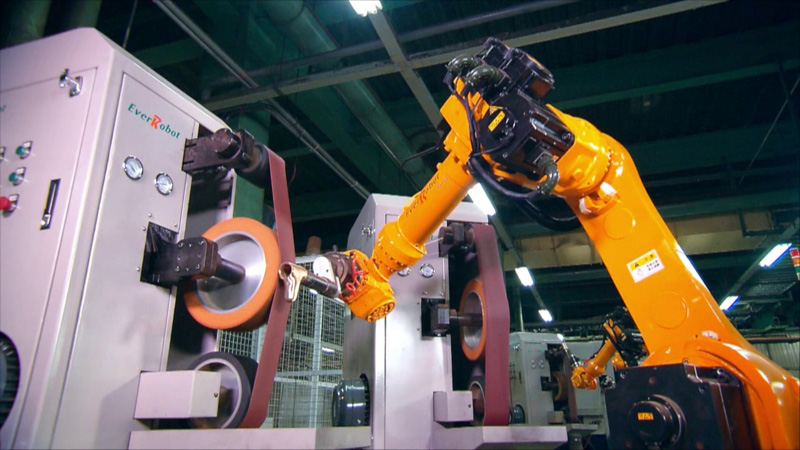

The use of robotics technology continues to evolve in many industries across the globe. One of the most innovative developments in this field is the use of Carbon Block Task Allocation Robots in carbon block production. These robots are equipped with high-precision sensors and advanced programming, ensuring accurate measurement and positioning of carbon blocks, and ultimately improving the quality of the end product.

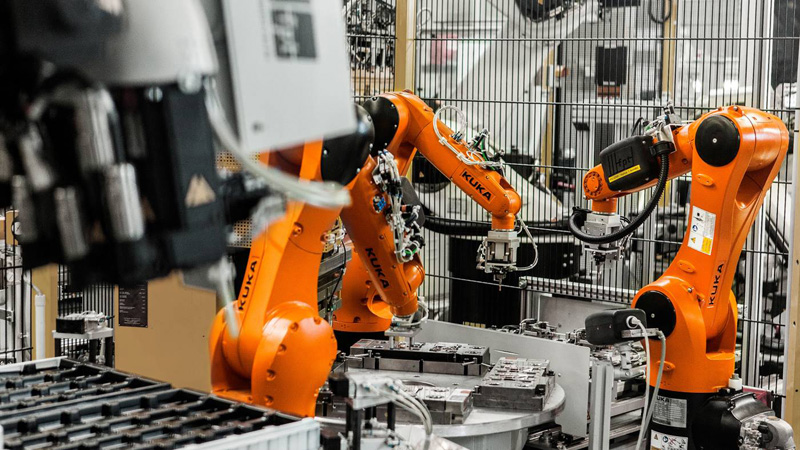

The Carbon Block Task Allocation Robots are an evolution of the Unimate Robot Arm, which was the first-ever industrial robot. Over the years, robotics technology has continued to advance, and today, robotics in logistics is becoming increasingly popular. For example, the Universal Robots UR5 is a collaborative robot used in many warehouses to help workers in packing and moving products.

In conclusion, the growing acceptance of robotics and automation technology in various sectors has revolutionized the way we work and produce products, with the carbon block task allocation robots becoming a valuable addition to many manufacturing processes. As technology continues to advance, the potential applications of robotics in other industries will only continue to grow.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

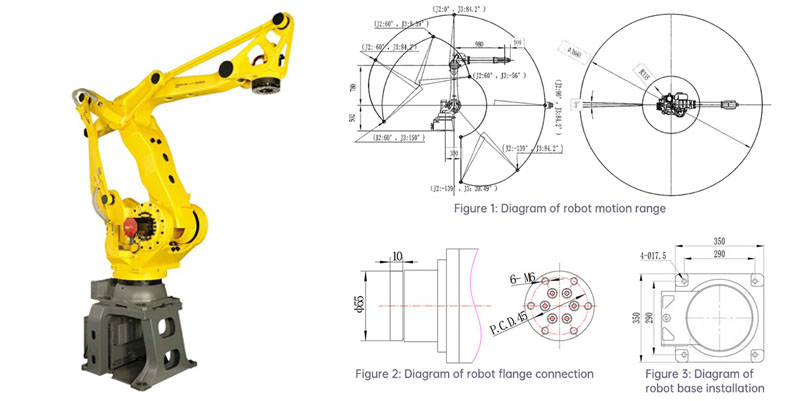

DIMENSIONAL DRAWINGS:

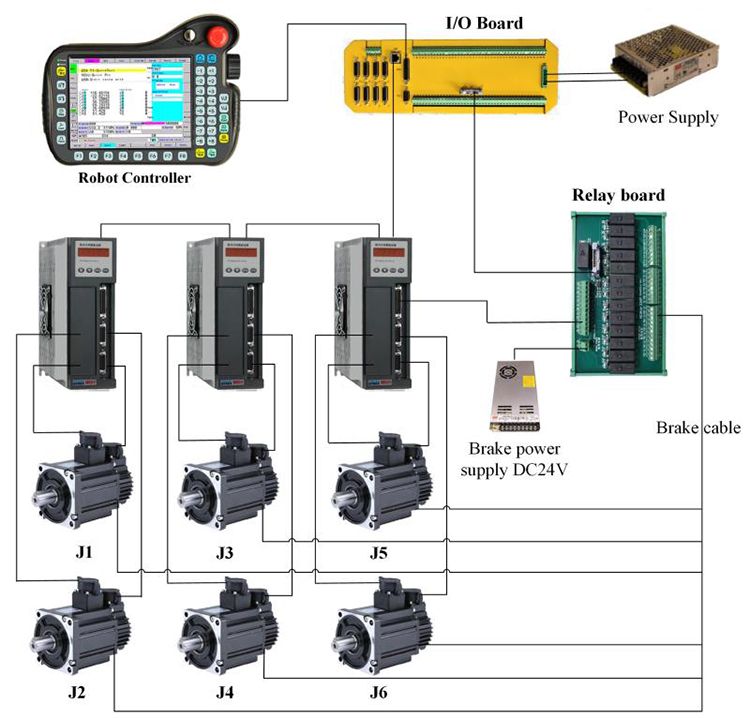

ROBOT CONTROLSYSTEM:

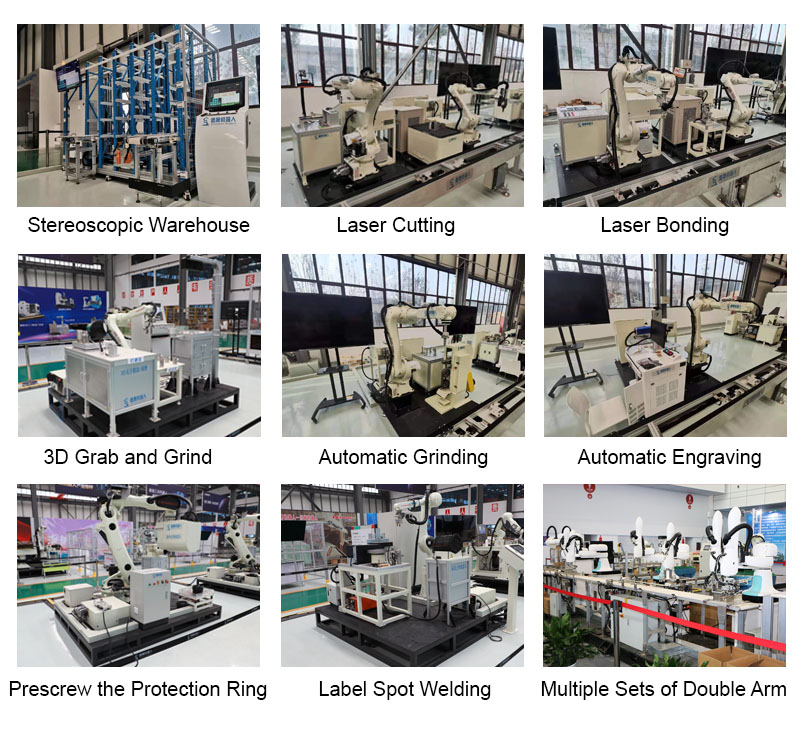

APPLICATIONS

1,Water treatment industry: Carbon Block Task Allocation Robots can be used in the water treatment industry where carbon blocks are used to remove impurities from water. The robots can be programmed to automatically allocate tasks such as the transportation of carbon blocks, cleaning, and maintenance of the filtration system, ensuring consistent and efficient operation.

2,Chemical industry: The robots can also be used in the chemical industry where carbon blocks are used in various industrial processes, such as adsorption, purification, and separation. The robots can be programmed to automatically perform tasks such as transporting, handling, and replacing carbon blocks, improving efficiency and safety in the workplace.

3,Environmental remediation: The robots can also be used in environmental remediation applications where carbon blocks are used to remove pollutants from soil or water. The robots can be programmed to allocate tasks such as the transportation and replacement of carbon blocks, ensuring efficient and consistent operation of the remediation process.

FEATURES:

1,Automation: The Carbon Block Task Allocation Robots can automate tasks that were previously performed manually, saving time and improving efficiency. The robots can be programmed to handle tasks such as transportation, cleaning, replacement, and maintenance, ensuring consistent operation of the filtration or industrial process.

2,Precision: The robots are designed to be precise and accurate, ensuring that the carbon blocks are properly placed and aligned in the filtration or industrial process. This precision can lead to improved filtration or purification performance and better product quality.

3,Safety: The use of Carbon Block Task Allocation Robots can also be safer than manual operation, as it reduces the risk of accidents and injuries. The robots can perform tasks such as heavy lifting and transportation, minimizing the need for workers to perform these tasks manually and reducing the risk of strain or injury.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: