Robots In Steel Industry

Robots In Steel Industry:

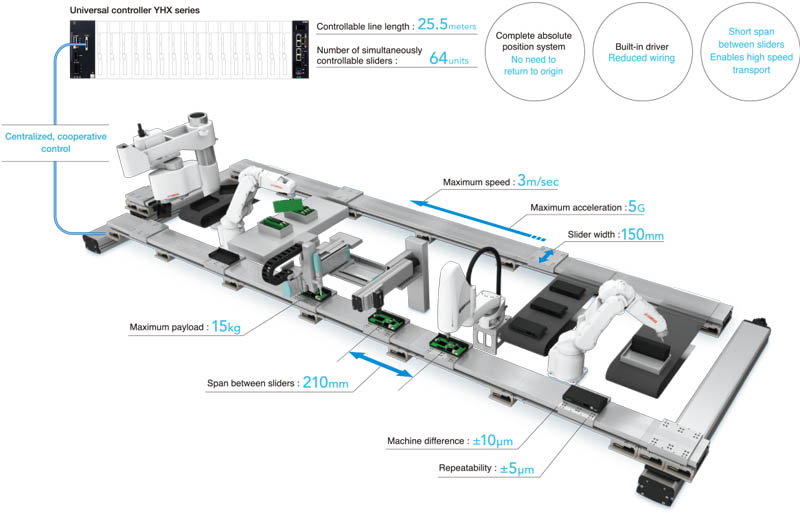

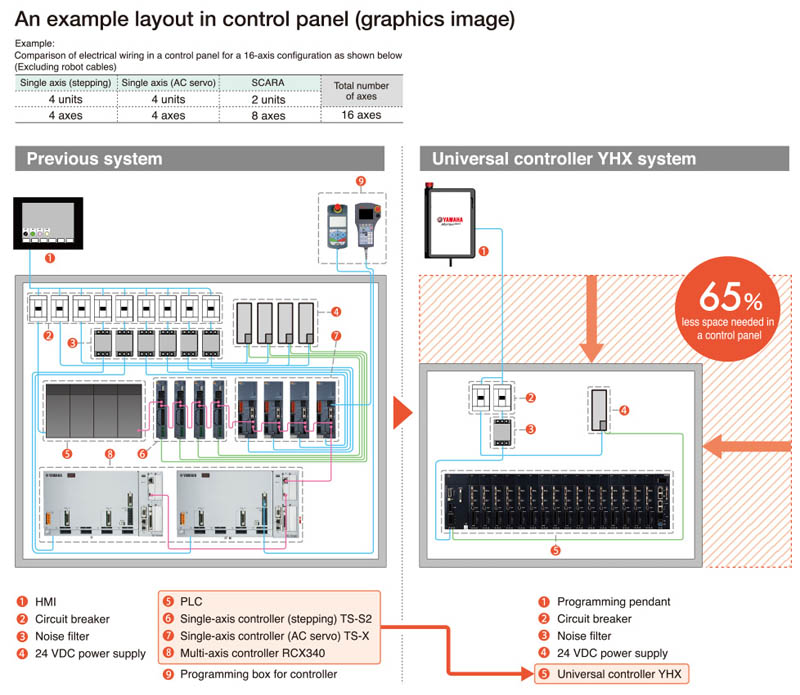

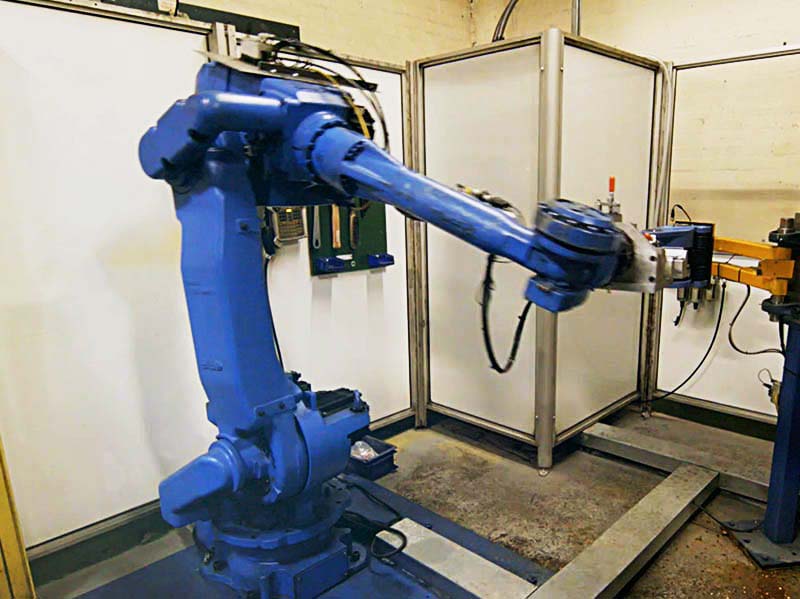

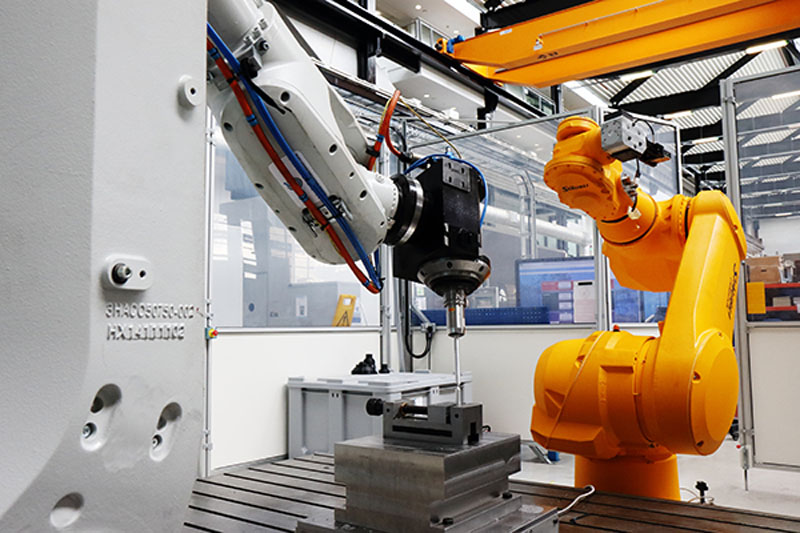

The advantages of robots in the steel industry include improved productivity, increased safety, and higher precision. Firstly, robots can work continuously without breaks or fatigue, leading to higher productivity levels. Secondly, by replacing human workers in dangerous and hazardous tasks, robots enhance workplace safety. Thirdly, robots have the ability to perform highly precise tasks, resulting in improved accuracy and quality control in the steel manufacturing process. Overall, the use of robots in the steel industry brings numerous benefits for efficiency, safety, and quality.

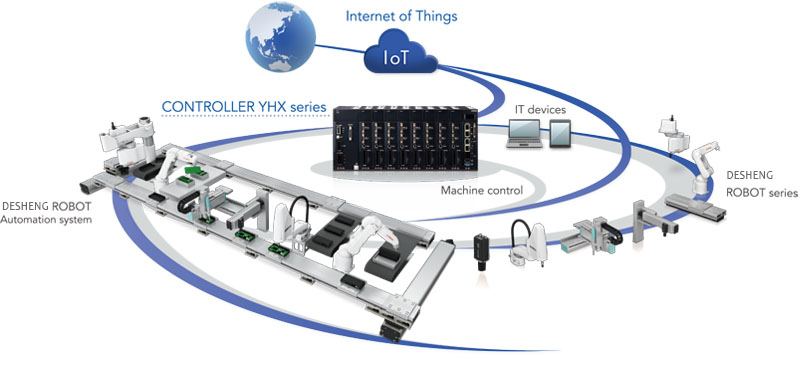

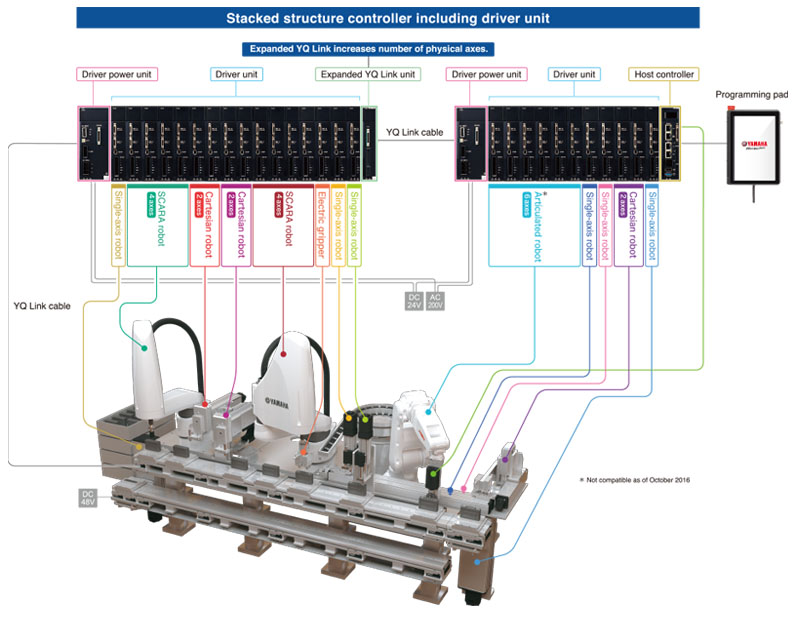

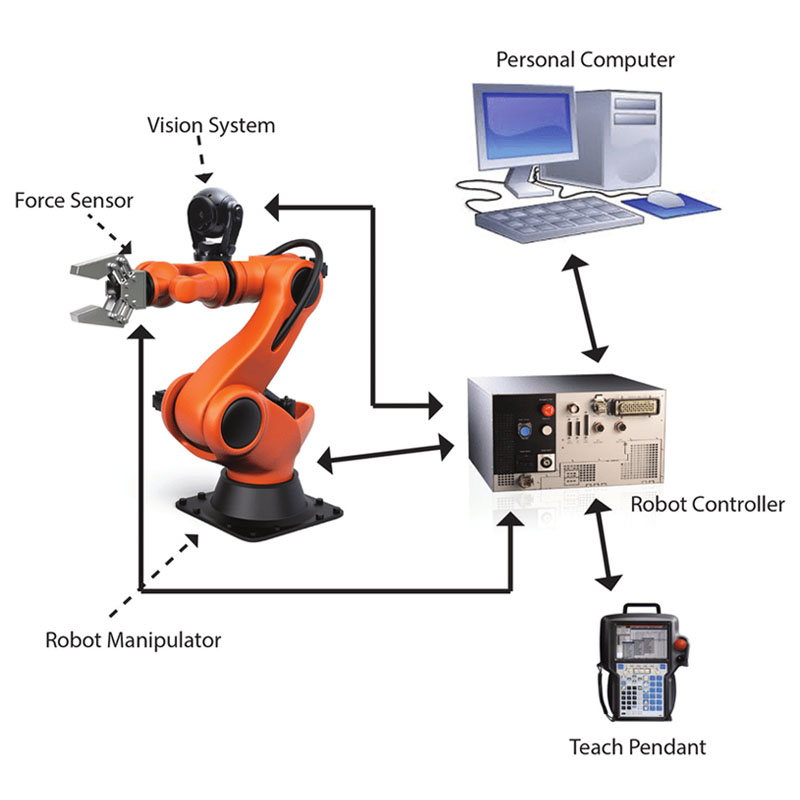

Robots have revolutionized the steel industry with the introduction of advanced technologies. The Gantry Automation System allows for efficient material handling and streamlines the production process. Robotic Arms using Arduino provide precise control and accuracy in performing complex tasks. Moreover, Personal Service Robots assist in various roles, such as maintenance and inspection, ensuring safety and efficiency. With these advancements, the steel industry has experienced improved productivity, enhanced safety, and superior product quality. Robots continue to play a crucial role in driving innovation and transforming the steel industry into a technologically advanced sector.