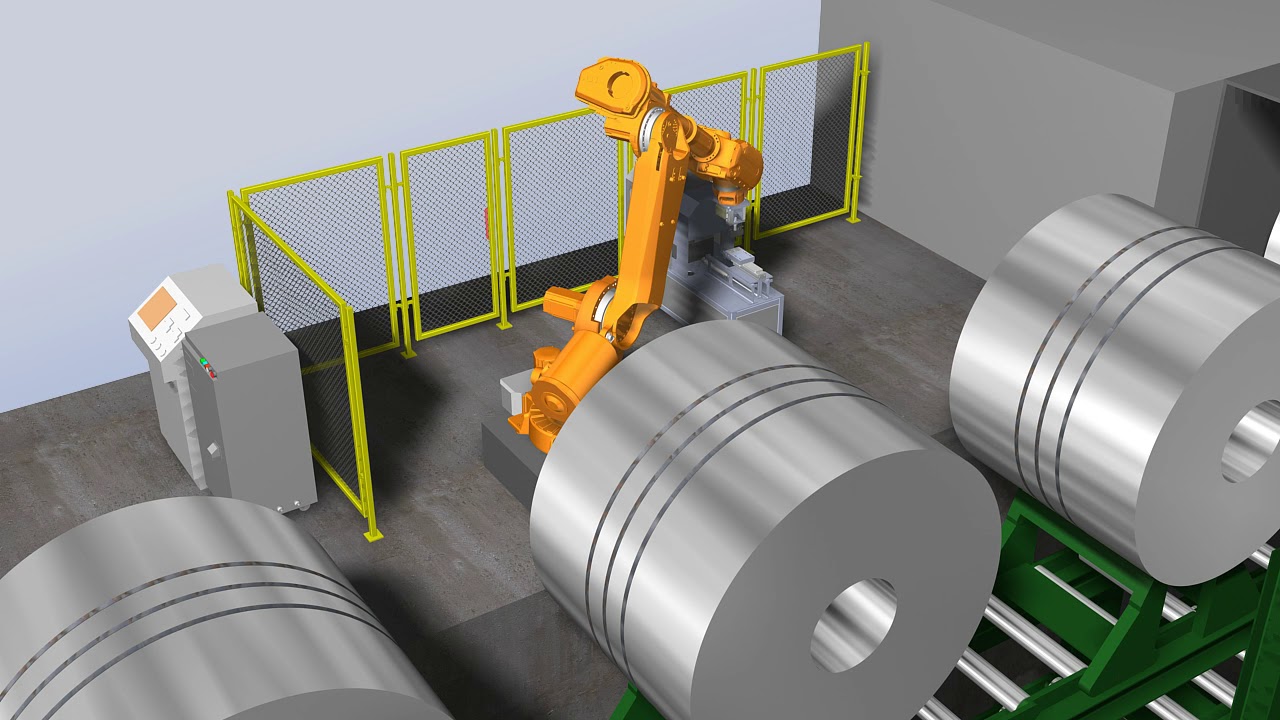

Robotics In Steel Industry

Robotics In Steel Industry:

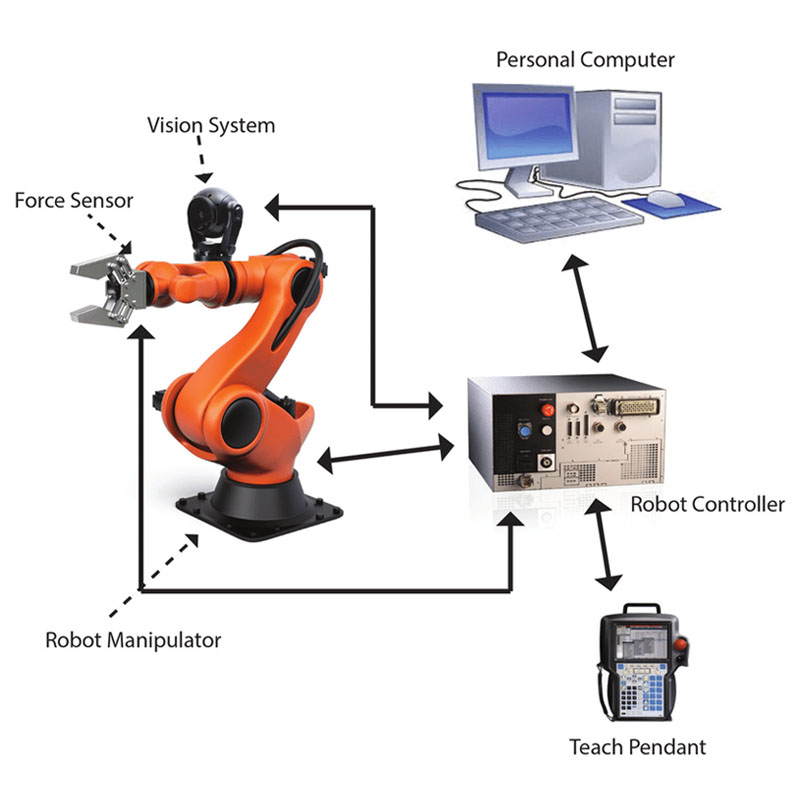

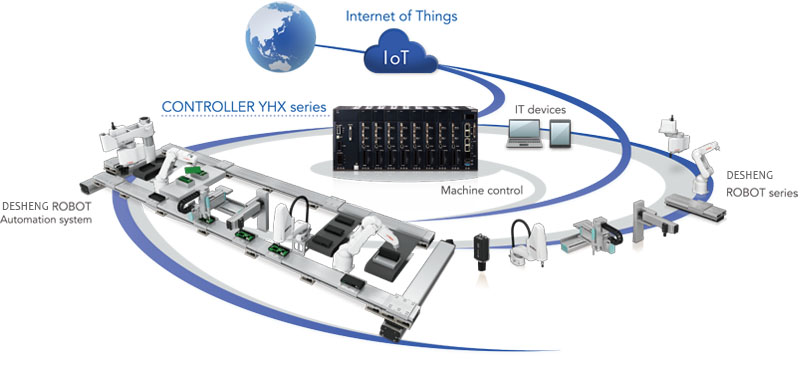

The advantages of robotics in the steel industry include increased efficiency, enhanced safety, and improved quality control. Robots enable continuous and precise operations, reducing production cycle times. They also eliminate human workers' exposure to hazardous conditions, improving safety. Additionally, robots perform tasks with accuracy, ensuring consistent product quality and allowing for automated inspections and measurements to detect defects.

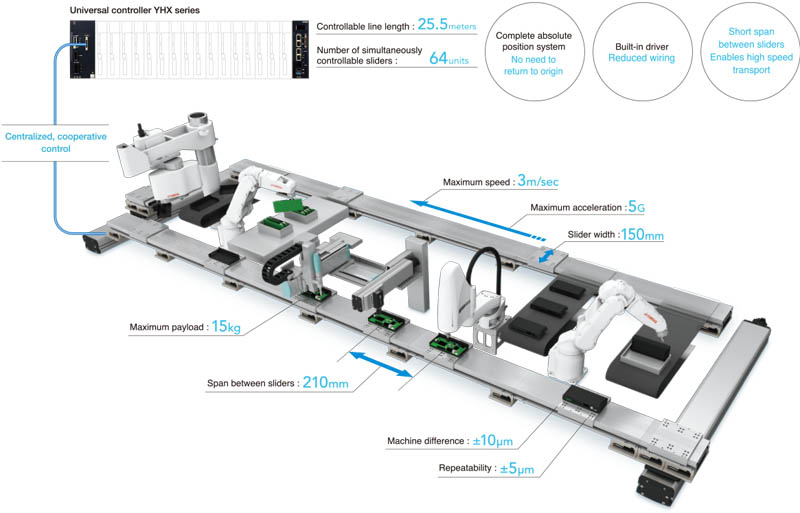

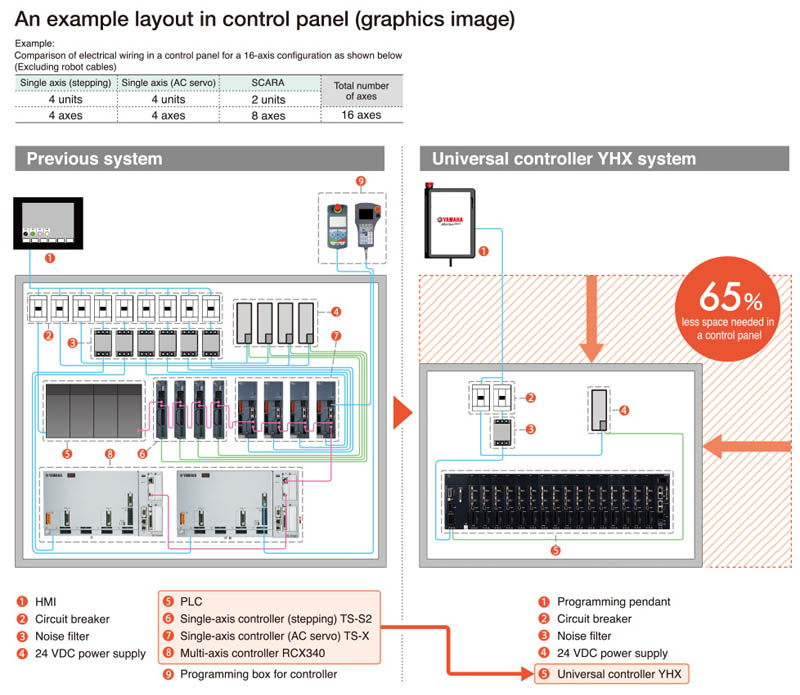

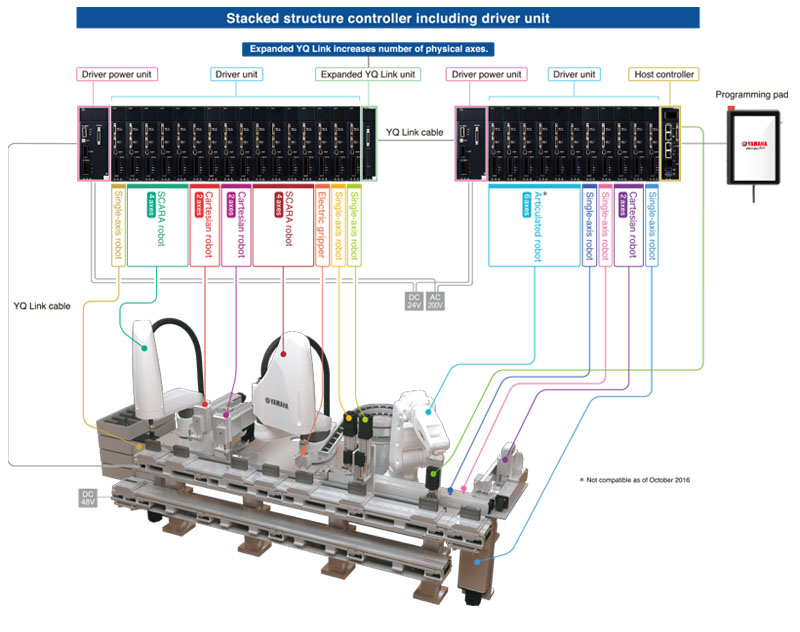

Please Contact Us For Detailed Technical Parameters.

Robotics In Steel Industry:

Robotics in the steel industry has seen significant growth in recent years. Robots are being extensively used in various processes, making the industry more efficient and productive. From welding and cutting to material handling, robots have proven their capabilities. Their precision and accuracy have resulted in higher quality products and reduced errors. Moreover, robots minimize the risk for workers by performing tasks in hazardous environments. The integration of robots in the steel industry has undoubtedly transformed operations, leading to increased productivity and improved safety standards.