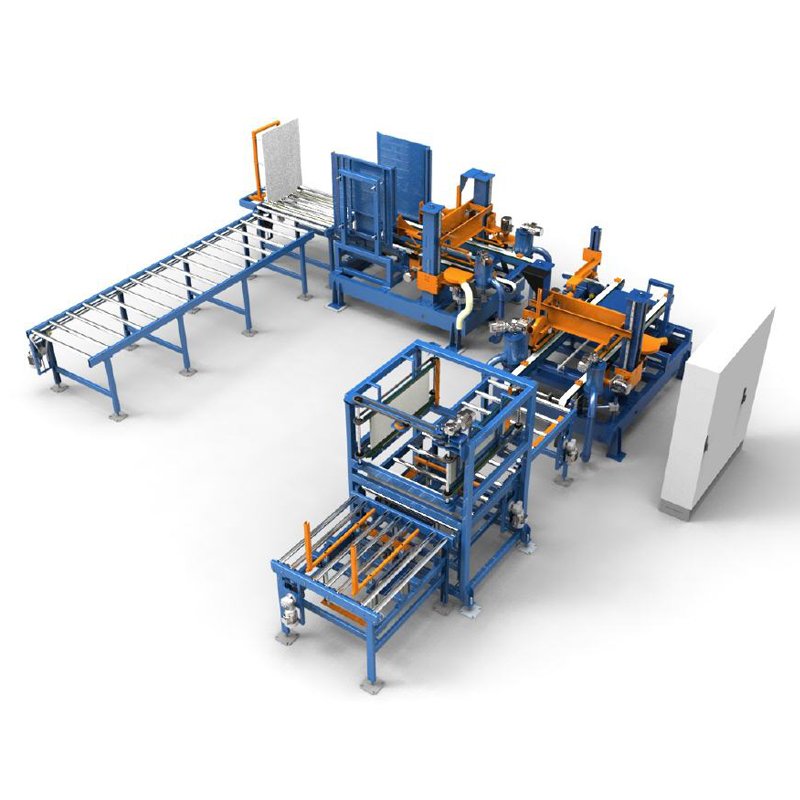

Machine Loading And Unloading Robots Solution

Machine Loading And Unloading Robots Solution:

1,Increased productivity: These robots can load and unload machines at a faster pace compared to manual labor, resulting in higher production rates and improved overall productivity.

2,Enhanced precision and accuracy: With their programmed movements, these robots ensure precise and accurate loading and unloading of materials or components into machines, reducing errors and maintaining consistency in the production process.

3,Improved worker safety: By automating the loading and unloading process, these robots help create a safer work environment by reducing the risk of injuries associated with manual handling. They can handle heavy or hazardous materials, eliminating the physical strain on human workers.

Please Contact Us For Detailed Technical Parameters.

Machine Loading And Unloading Robots Solution:

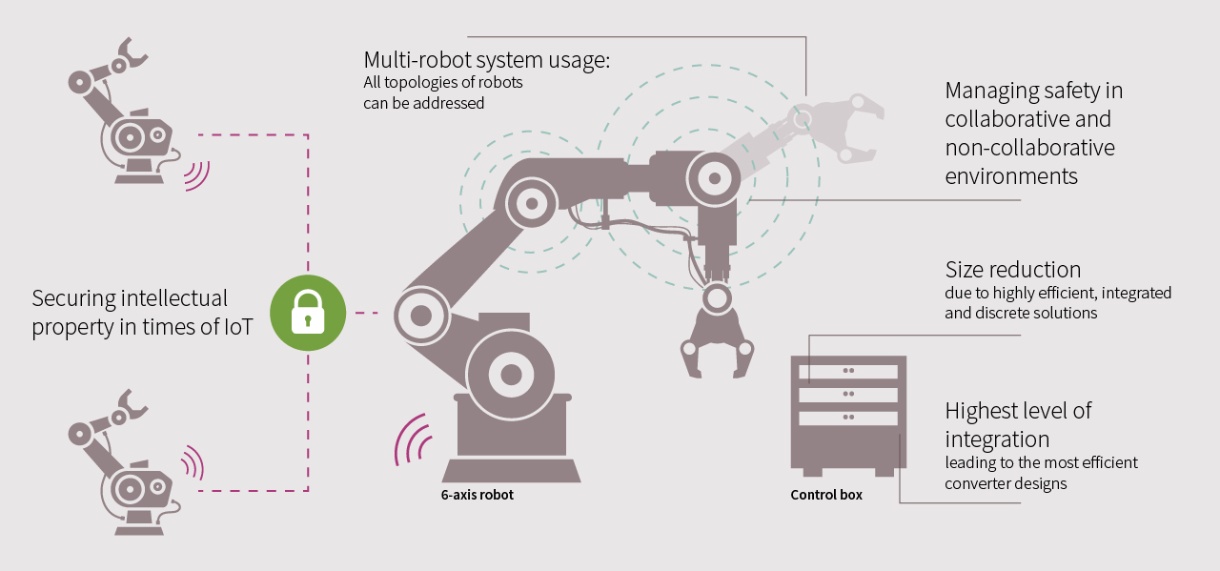

Machine Loading And Unloading Robots, integrated with automation robotics and machine solutions, are transforming the manufacturing industry. Machine Loading And Unloading Robots Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters.The Qualcomm Robotics RB6 platform, along with other industrial robots and automation solutions, offers several advantages. These robots enable efficient and precise loading and unloading of materials into machines, enhancing productivity and reducing human errors. The Qualcomm Robotics RB6 platform provides advanced capabilities for robot control and navigation, ensuring seamless integration into existing manufacturing processes. Industrial robots and automation solutions, equipped with versatile capabilities, optimize efficiency and streamline operations. With the integration of machine loading and unloading robots, industries can experience increased productivity, improved accuracy, and reduced labor costs. These innovative solutions redefine the manufacturing landscape, paving the way for a more efficient and automated future.

SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

Robot Arm | Japanese Brand Robot | Fanuc | Kawasaki | |

German Brand Robot | KUKA | |||

Switzerland Brand Robot | ||||

Main Performance | Speed Capacity | 8s Per Cycle | Adjust according to products and | |

Weight | About 8000kg | |||

Applicable Product | Cartons,Cases,Bags, | Containers,Bottles,Cans,Buckets etc | ||

Power and Air | Compressed Air | 7bar | ||

Electric Power | 17-25 Kw | |||

Voltage | 380v | 3 Phases | ||

PLC | Siemens | |||

Frequency Converter | Danfoss | |||

Photoelectric Sensor | Sick | |||

Servo Motor | Panasonic | |||

Pneumatic Component | SMC | |||

Low-voltage Apparatus | Schneider | |||

Touch Screen | SchneiderlSiemens | |||

Driving Motor | SEW | |||

SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

Robot Arm | Japanese Brand Robot | Fanuc | Kawasaki | |

German Brand Robot | KUKA | |||

Switzerland Brand Robot | ABB | |||

Main Performance | Speed Capacity | 8s Per Cycle | Adjust according to products and | |

Weight | About 8000kg | |||

Applicable Product | Cartons,Cases,Bags, | Containers,Bottles,Cans,Buckets etc | ||

Power and Air | Compressed Air | 7bar | ||

Electric Power | 17-25 Kw | |||

Voltage | 380v | 3 Phases | ||

PLC | Siemens | |||

Frequency Converter | Danfoss | |||

Photoelectric Sensor | Sick | |||

Servo Motor | Panasonic | |||

Pneumatic Component | SMC | |||

Low-voltage Apparatus | Schneider | |||

Touch Screen | SchneiderlSiemens | |||

Driving Motor | SEW | |||