Robots In Fast Food Industry

Robots In Fast Food Industry

The advantages of robots in the fast food industry include increased efficiency, improved accuracy, and reduced labor costs. Robots can perform repetitive tasks with high speed and precision, resulting in faster service and fewer errors. They can also work continuously without breaks or fatigue, ensuring consistent productivity. Additionally, robots eliminate the need for human workers in certain positions, reducing labor costs and potentially increasing profits. Overall, the use of robots in the fast food industry can enhance operational efficiency and profitability.

Robots In Fast Food Industry

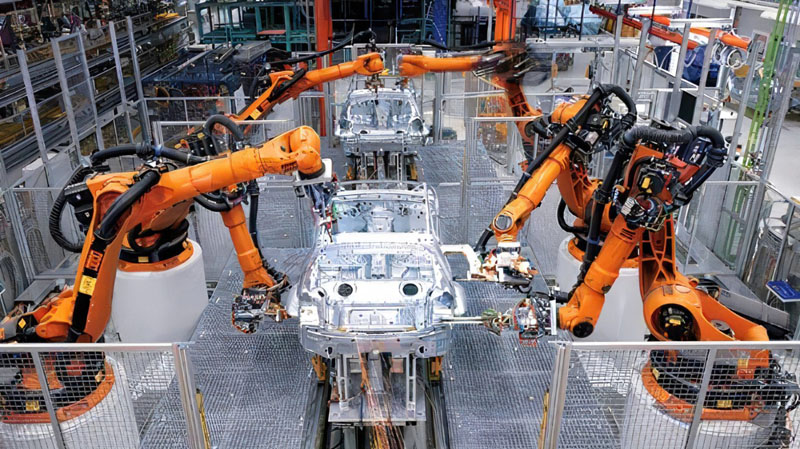

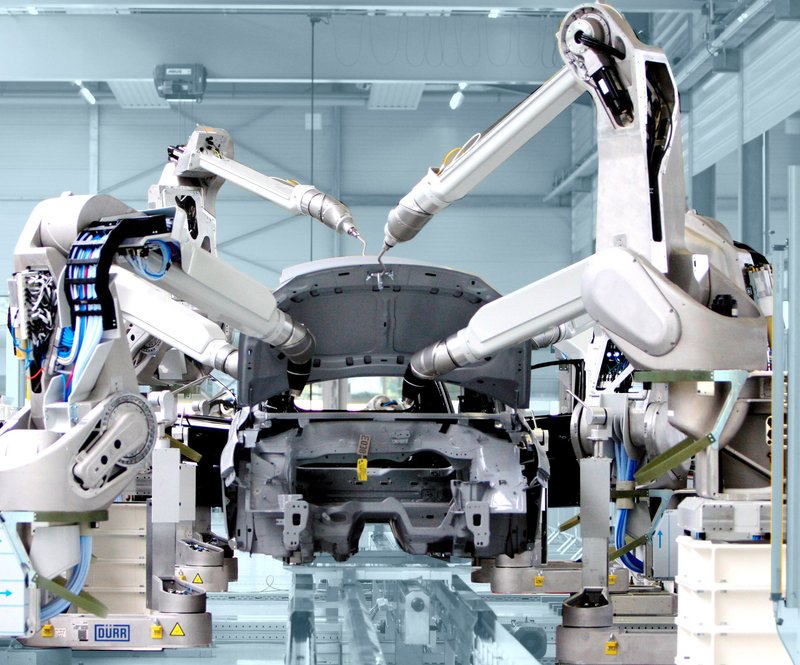

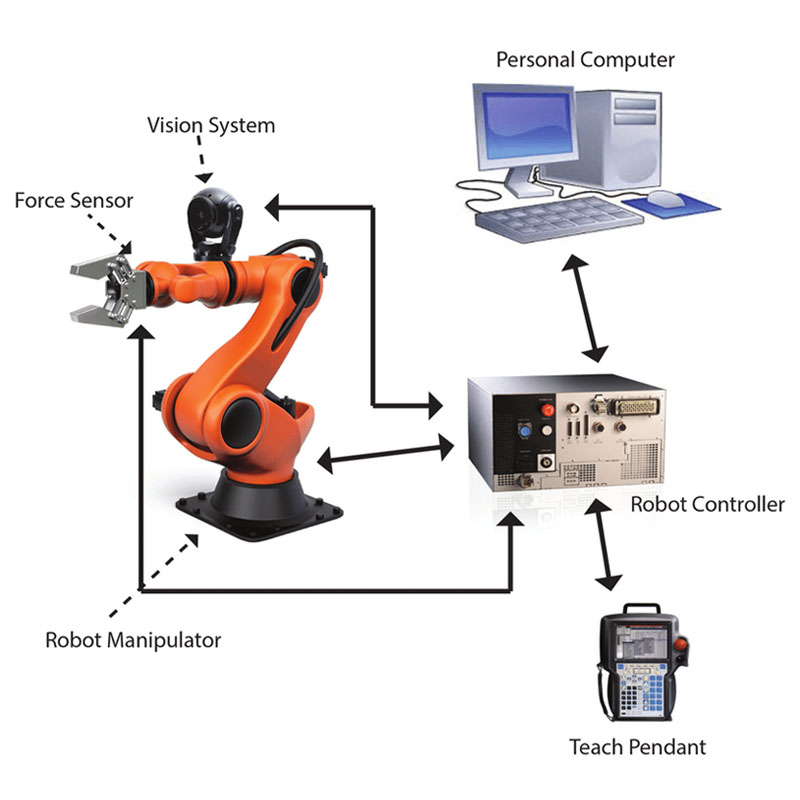

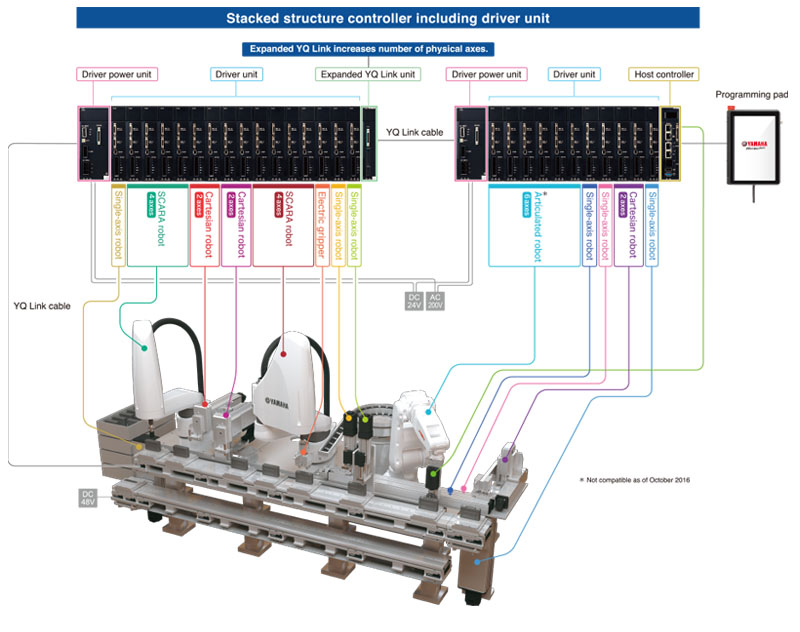

Robots have revolutionized the fast food industry, making processes more efficient and streamlined. Qualcomm Robotics Rb6, Mir 250 Robot, and Kuka Kr 6 r700 Sixx are some of the popular robots used in this industry.

The Qualcomm Robotics Rb6 is a versatile robot that can perform various tasks, such as cooking, cleaning, and serving customers. Its advanced technology ensures accuracy and speed in food preparation, leading to faster service and satisfied customers.

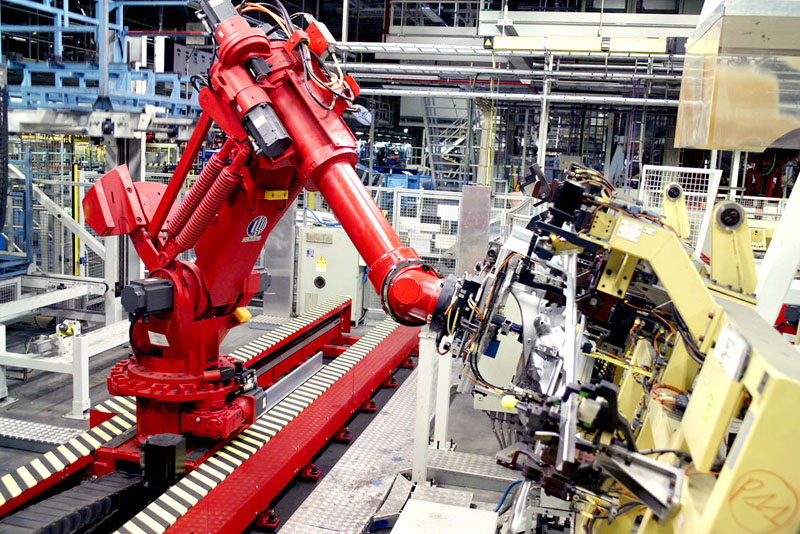

The Mir 250 Robot is designed to handle heavy loads and navigate through crowded spaces. It can transport ingredients and equipment, reducing the need for human labor and increasing productivity in fast food restaurants.

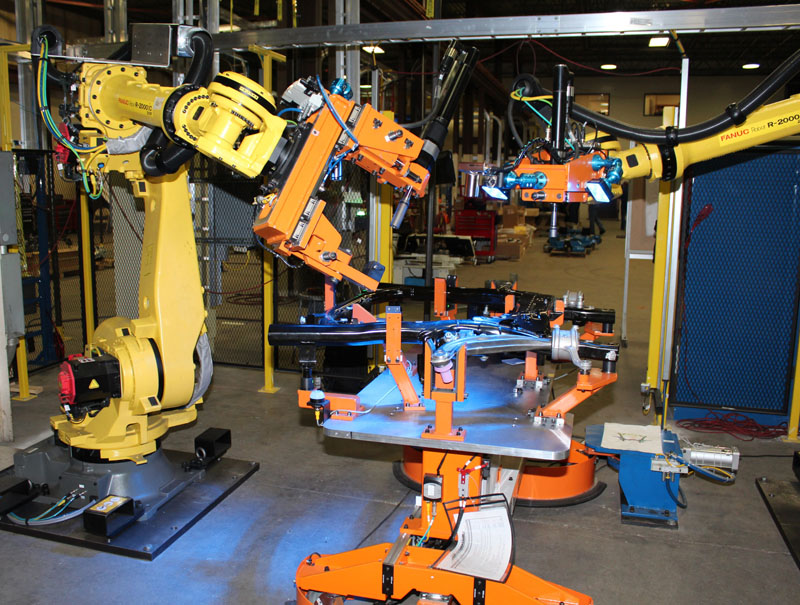

The Kuka Kr 6 r700 Sixx is a robotic arm that can be programmed to perform precise tasks, such as assembling burgers or packaging food items. Its flexibility and precision make it an ideal choice for fast food chains looking to automate their processes.

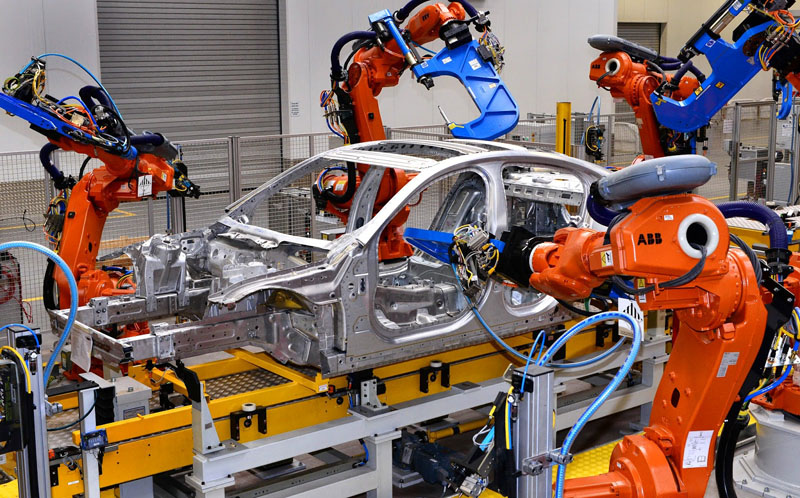

These robots not only improve efficiency but also enhance food safety by minimizing human contact with the food. They are also cost-effective in the long run, as they reduce labor costs and increase productivity.

In conclusion, robots like Qualcomm Robotics Rb6, Mir 250 Robot, and Kuka Kr 6 r700 Sixx have transformed the fast food industry, making it more efficient, safe, and cost-effective.