Cobots For The Automobile Assembly Line

Cobots For The Automobile Assembly Line:

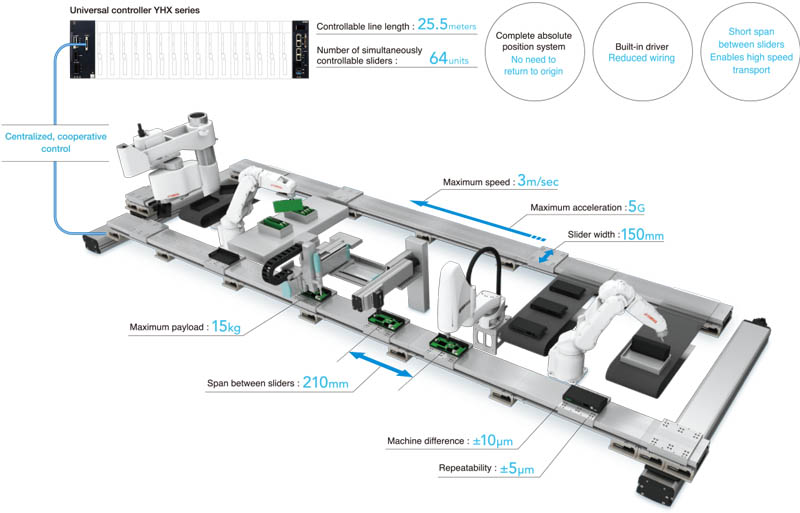

1,Increased productivity: Cobots in the automobile assembly line can work alongside human workers, carrying out repetitive and monotonous tasks with high speed and accuracy, leading to increased overall productivity in the assembly process.

2,Enhanced safety: Cobots are designed to operate safely alongside humans, equipped with sensors and software that allow them to detect and avoid any potential collisions or accidents. This improves safety for workers on the assembly line, reducing the risk of injuries and accidents.

3,Improved efficiency: Cobots can work continuously without fatigue, leading to a more efficient assembly line process. They can also quickly adapt and adjust to changing production demands, allowing for a flexible and responsive production line. This enables faster production cycles and reduced product lead times.

Cobots For The Automobile Assembly Line:

Cobots For The Automobile Assembly Line have revolutionized the automotive industry. Robot Kuka Kr16-2 and hydraulic robot arm are two popular examples. These robotic arms provide numerous advantages. Firstly, they enhance productivity by efficiently carrying out repetitive tasks with high precision. Secondly, they ensure worker safety as they are equipped with sensors to detect and avoid any potential accidents. Lastly, ABB Spray Painting Robot brings improved efficiency and quality to the painting process, resulting in flawless finishings. In conclusion, these advanced cobots and robots have transformed the assembly line, making it more productive, safer, and efficient in the automotive industry.