Cobots For The Automobile Assembly Line

Advantages of Cobots For The Automobile Assembly Line:

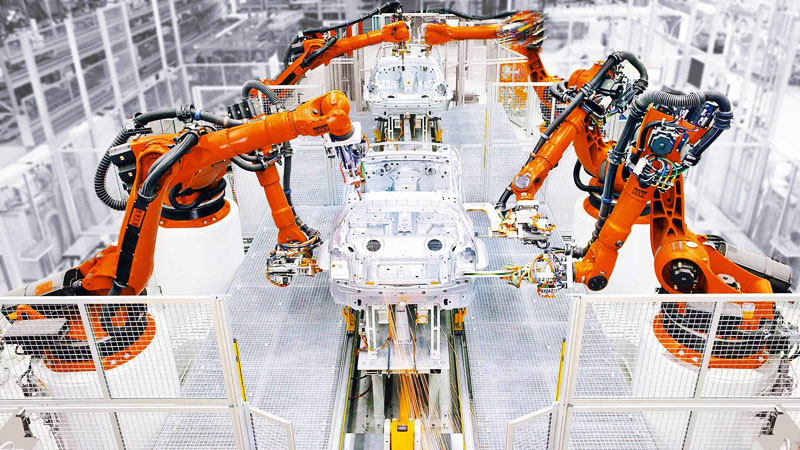

1,Improved safety: Cobots for the automobile assembly line are designed to work alongside human workers safely, providing additional safety measures for those working on the assembly line. This makes it a popular solution in automotive industries concerned with worker safety, such as Google Automotive.

2,Increased productivity: Collaborative robots can work alongside human workers to improve assembly line efficiency and productivity, allowing for more output each day. This is especially valuable in automated production lines, where uninterrupted flow is key to a successful production process.

3,Flexibility and adaptability: Cobots can quickly adapt to new assembly line processes and requirements, providing a highly adaptable solution for automotive manufacturing. This makes them a valuable addition to an automated production line definition, allowing for a more efficient and streamlined production process.

Cobots For The Automobile Assembly Line:

Collaborative robots, or cobots, are changing the face of automotive manufacturing. Popular automobile industries such as Google Automotive are implementing cobots on the assembly line to improve safety, increase productivity, and enhance flexibility and adaptability. With automated production line definition becoming more widespread, cobots are proving to be a valuable addition to the process. The safety features of cobots make them a popular solution for automotive industries concerned with worker safety. Cobots can work alongside human workers to improve assembly line efficiency and productivity, allowing for more output each day. Their flexibility and adaptability make them a valuable addition to automated production lines, providing a highly adaptable solution for automotive manufacturing. With cobots revolutionizing the assembly line process, we can expect to see the role of human workers change, with increased collaboration with cobots becoming the norm in the automotive industry.

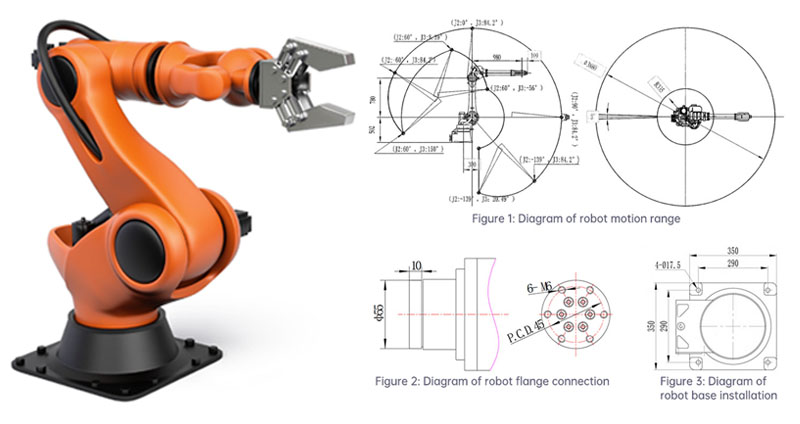

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

DIMENSIONAL DRAWINGS:

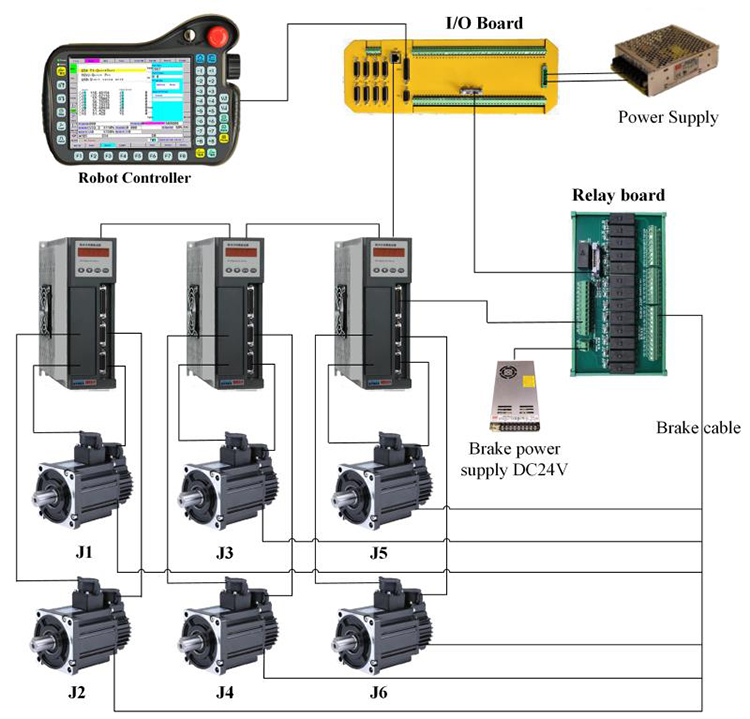

ROBOT CONTROLSYSTEM:

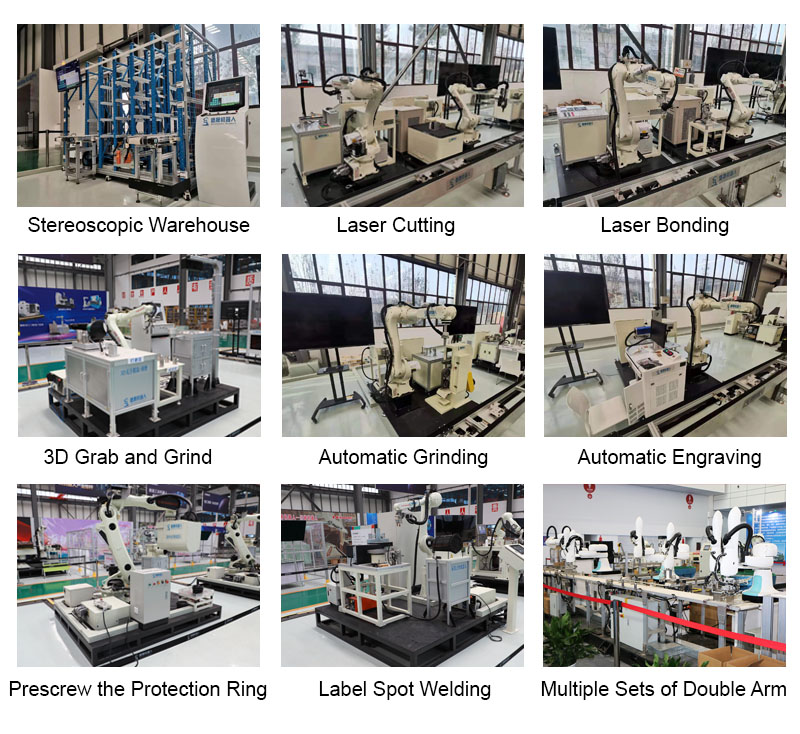

APPLICATIONS:

1,Assembly of car parts: Cobots for the automobile assembly line can be used to assist with the assembly of car parts. This can include tasks such as inserting screws and bolts, applying adhesives, and installing windows and doors.

2,Painting of car bodies: Collaborative robots can also be used to paint car bodies, which is a highly repetitive and physically demanding task. They can be programmed to apply paint quickly and consistently, improving the efficiency and quality of the painting process.

3,Inspection and quality control: Cobots can also be used for inspection and quality control purposes. They can be equipped with sensors and cameras to detect defects and ensure that car parts and components are assembled to the required standards.

FEATURES:

1,Collaborative: Cobots for the automobile assembly line are designed to work alongside human workers safely, using enhanced sensors and safety features. This collaborative design allows for improved efficiency and productivity in the manufacturing process.

2,Customizable: Collaborative robots can be programmed and reprogrammed to perform specific tasks with a high degree of accuracy, depending on the needs of the production line. This customizable design makes them an adaptable solution for different assembly line processes and requirements.

3,Low maintenance: Cobots require minimal maintenance and can continue working 24/7 without breaks or downtime. This low maintenance design makes them a cost-effective solution for the automotive industry, as they can operate continuously for extended periods of time.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: