Efficient Intelligent Welding Automation Solution

Efficient Intelligent Welding Automation has brought about significant improvements in the manufacturing industry, with the help of robotic welding arms and pipe welding robots. The ease of operation of these machines is made possible through the design of teach pendant buttons that are user-friendly and easy to comprehend, and the programming process can be mastered quickly. Furthermore, these machines automatically stop if an incorrect operation occurs, which helps to reduce the risk of equipment damage. These features ensure optimal efficiency, productivity, and safety in manufacturing processes. While the initial cost of a robotic welding machine may be significant, the potential for increased productivity leads to a quick return on investment.

Please Contact Us For Detailed Technical Parameters.

Efficient Intelligent Welding Automation has brought about major improvements in the welding industry, Robot Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters.With robotic welding arms and pipe welding robots leading the way. These machines offer faster welding times and higher precision, leading to increased productivity and efficiency. While the initial cost of a robotic welding machine may be significant, their ability to reduce labor costs allows for a quick return on investment. The rise of Welding Automation is making it possible for businesses to take on larger-scale projects while minimizing errors and safety risks. With the continued advancements in technology, we can expect to see an even greater impact on the future of welding.

PARAMETERS:

DS Robot arm- Welding Series (Dust Proof type) | ||||

Model | DS-H1500-B-6 | DS-H1850-B-6 | DS-H2100-B-6 | |

Payload | 6kg | 6kg | 6kg | |

Active radius/Reaching | 1500mm | 1850mm | 2100mm | |

structure | Articulated | Articulated | Articulated | |

Axes | 6 | 6 | 6 | |

Repeatability | ±0.05 | ±0.05 | ±0.05 | |

Protection class | 1P65 | IP65 | IP65 | |

Max motion | J1 | ±165° | ±165° | ±165° |

J2 | +135/-75° | +135/-75R | +135/-75° | |

J3 | 78/-76.5 | 78/-76.5 | 78/-76.5 | |

J4 | ±360° | ±360° | ±360° | |

J5 | ±115R | ±115R | ±115 | |

J6 | 450° | ±450° | ±450° | |

Max speed | J1 | 148°/sec | 148°/sec | 148°/sec |

J2 | 148°/sec | 148°/sec | 148°/sec | |

J3 | 150°/sec | 150°/sec | 150°/sec | |

J4 | 222°/sec | 222°/sec | 222°/sec | |

J5 | 222°/sec | 222°/sec | 222°/sec | |

J6 | 360°/sec | 360°/sec | 360°/sec | |

Weight | 150kg | 170kg | 235kg | |

Installation method | Groud,bracket celling | Groud , bracket, celling | Groud, bracket, celling | |

Ambient temperature | -20℃ ~ 80℃ | -20℃ ~ 80℃ | -20℃ ~ 80℃ | |

DS Robot arm - Welding Series (Hollow type) | |||

Model | DS-HZ1500-B-6 | DS-HZ1850-B-6 | |

Payload | 6kg | 6kg | |

Active radius/Reaching | 1500mm | 1850mm | |

Structure | Articulated | Articulated | |

Axes | 6 | 6 | |

Repeatability | ±0.05 | ±0.05 | |

Protection class | IP65 | IP65 | |

Max motion | J1 | ±165° | ±165° |

J2 | +135°/-90° | +135°/-90° | |

J3 | +90°/-90° | +90°/-90° | |

J4 | ±360° | ±360° | |

J5 | +115°/-140° | +115°/-140° | |

J6 | ±450° | ±450° | |

Max speed | J1 | 148°/sec | 148°/sec |

J2 | 148°/sec | 148°/sec | |

J3 | 150°/sec | 150°/sec | |

J4 | 222°/sec | 222°/sec | |

J5 | 222°/sec | 222°/sec | |

J6 | 360°/sec | 360°/sec | |

Weight | 150kg | 170kg | |

Installation method | Groud,bracket, celling | Groud, bracket, celling | |

Ambient temperature | -20℃~80℃ | -20℃~80℃ | |

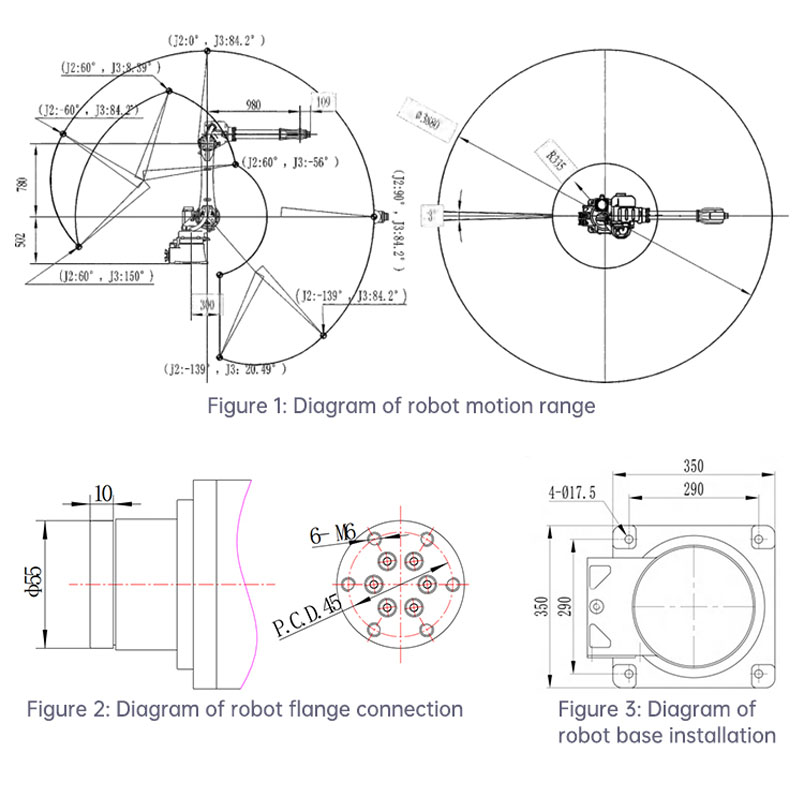

DIMENSIONAL DRAWINGS:

ROBOT CONTROLSYSTEM:

FEATRUES:

Robotic Arm

The robot am is made of aluminum castings through a CNC machining center,and the surface is sprayed to achieve a beautiful.

Constant Arc Length Control

All sublocal speed inverter control, quickly adjust thearc voltage to achieve the stability of the welding procession & a wide arc voltage range.

Reserved Cable Hole

The robot arm has reserved cable holes,which are beautiful and do not hinder theoperation of the manipulator.The end of the tracheais reserved for the port and the data cable connector.

Robot Welding Gun

Flexible for changing welding tasks,the lengthof the welding gun can be customized,the wirefeeding is more stable,and it can handle comple work.

Storage | 2GB |

Teaching box | Full keyboard+touch screen, mode select switch, safety |

No.of controlled axis | 6+6 axis,6 basic axes +6 external axis |

lnterface | Multiple encoder signal interfaces,dedicated interface for robot |

Safety module | The emergency and robot anomaly signals are linked to ensure rapid |

Mode of operation | Teaching,representation, remote control |

Mode of programming | Online teaching,process programming, teaching by dragging |

Motion function | Point-to-point, linear, circular |

Command system | Motion, logic,process,computation |

Mode of control | Position control |

Anomaly detection | Emergency stop anomaly,servo anomaly,anti-collision, safety maintenance, |

APPLICATIONS:

The following fields are the primary ones wherein laser welding robots are used, and when in comparison to humans, their work excellent and efficiency are some distance better than the ones of synthetic approach.

1, The production of machines

2. Cars and automobile elements

3. Extracting coal

4. Resources

5. Aviation

AFTER-SALES SERVICE:

1,Three hundred and sixty five days for the primary additives (engine, axle, body, beam, and so forth.).

2,Technical assistance is available 24/7 by using telephone, whatsapp, or e-mail.

3,Supports for lifetime elements.

4,Remote places engineering services handy.

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS: