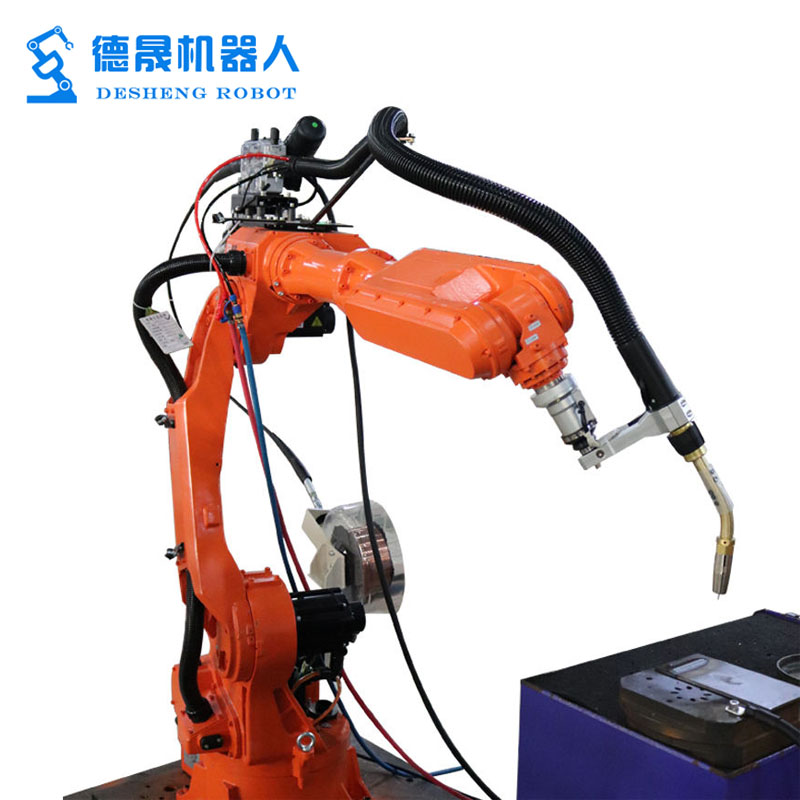

Robot Laser Welding Machine

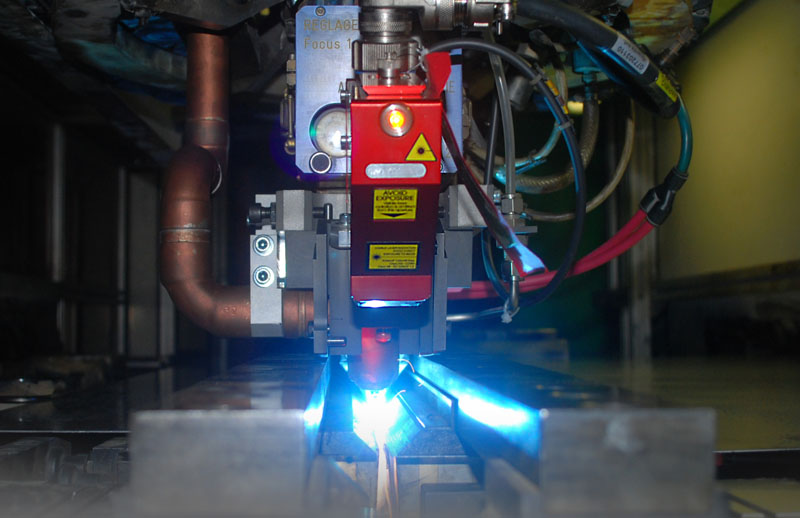

Robot laser welding machine can effectively improve the quality of welding, more and more widely used, such as car chassis, seat skeleton, muffler, guide rail and hydraulic torque converter welding are widely used to open robot laser welding, greatly improve the work efficiency.

Pipe welding robots have become increasingly popular in the welding industry due to their ability to perform accurate and efficient welding operations. Robotic Welding Machines have revolutionized the industry, offering advanced technologies and numerous benefits like improved productivity, consistency, and safety. The Robot Laser Welding Machine is a prime example of such advancements, providing pinpoint accuracy for high-quality welds. These machines can complete precise and complex welding tasks with minimal human intervention. Additionally, laser welding robots have gained popularity for their ability to achieve high welding speeds without causing excessive heat-affected zones. In today's competitive welding industry, investing in Robotic Welding Machines like pipe welding robots has become essential to stay ahead of the game and meet the growing demands of the industry.

Parameters:

Popular welding robot models and parameters | ||||||

Model | Rated load | Effective Armspread | Robot type | Rated positiong accuracy | Power capacity | Robot weight |

QJRH4-1A | 4kg | 1410mm | 6 axis industrail robot | 士0.03mm | 2.7KVA | 150kg |

QJR6S-1 | 6kg | 750.6mm | 6 axis industrail robot | ±0.02mm | 1.5KVA | 39g |

QR6-1 | 6kg | 1441mm | 6 axis industrail robot | ±0.03mm | 2.7KVA | 170kg |

QR6-2 | 6kg | 1481mm | 6 axis industrail robot | 士0.03mm | 2.7KVA | 185kg |

QR6-3 | 6kg | 2001mm | 6 axis industrail robot | ±0.05mm | 3.8KVA | 255kg |

QJR10-1 | 10kg | 1671mm | 6 axis industrail robot | ±0.05mm | 3.3KVA | 250kg |

QR10-2 | 10kg | 2001mm | 6 axis industrail robot | ±0.05mm | 4.2KVA | 275kg |

QJRB20-1 | 20kg | 1671mm | 6 axis industrail robot | ±0.05mm | 3.6KVA | 270kg |

Details:

Features:

1. Use welding platform, heavy type guide rail increase whole loading capacity, and humanized structure design, human-machine exchange is more reasonable and convenient, stable operation increase lifespan.

2. Self-developed pipe optimization CNC control system. AutoCAD type engineer design drawing can generate standard G code, three-dimensional simulation operation, node expansion, over length pipe split, pipe optimization, etc. Software compatibility with EGES DXF SAT and STL, etc. And lifelong upgrade and modification service according to clients’ technical requirements.

3. Advantech industrial computer can be programmable for machine directly. Use menu type choose input cutting parameters, such as external diameter, thickness, beveled edges angle, deviation, compensation data ,etc. To make seamless connection through professional pipe cutting application program.

Applications:

Laser welding robot compared with human, whether the work quality or efficiency will be far higher than artificial, laser welding robot application is very wide, the following fields are the main application field of welding robot.

1, machinery manufacturing field

2. Automobile and auto parts

3. Coal mining

4. Equipment

5. Aerospace

After-Sales Service:

1,12 months for main parts(engine,axle,body and beam,etc).

2,24/7 technical support through phone, Whatsapp, or email.

3,Lifelong Parts Supports.

4,Engineer available service oversea.

Package and shipping:

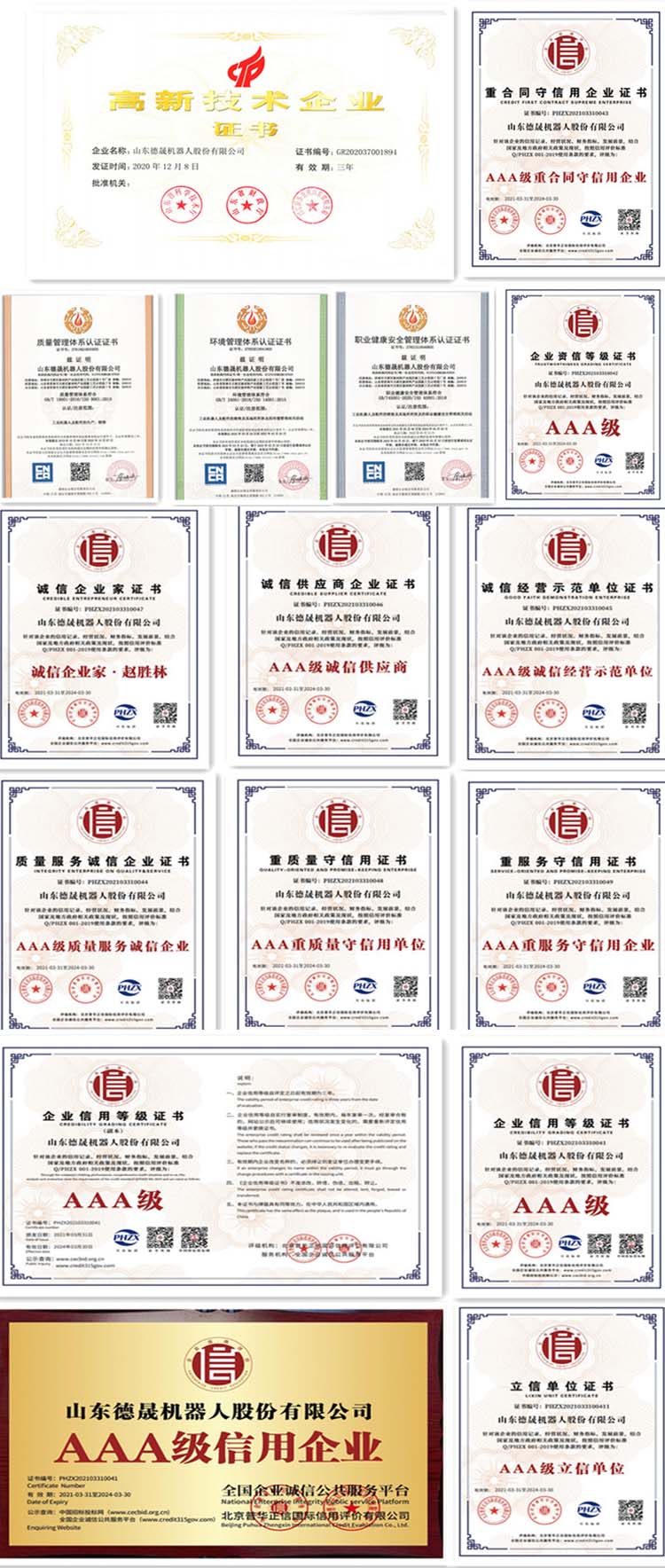

Certifications:

Cooperation Partner:

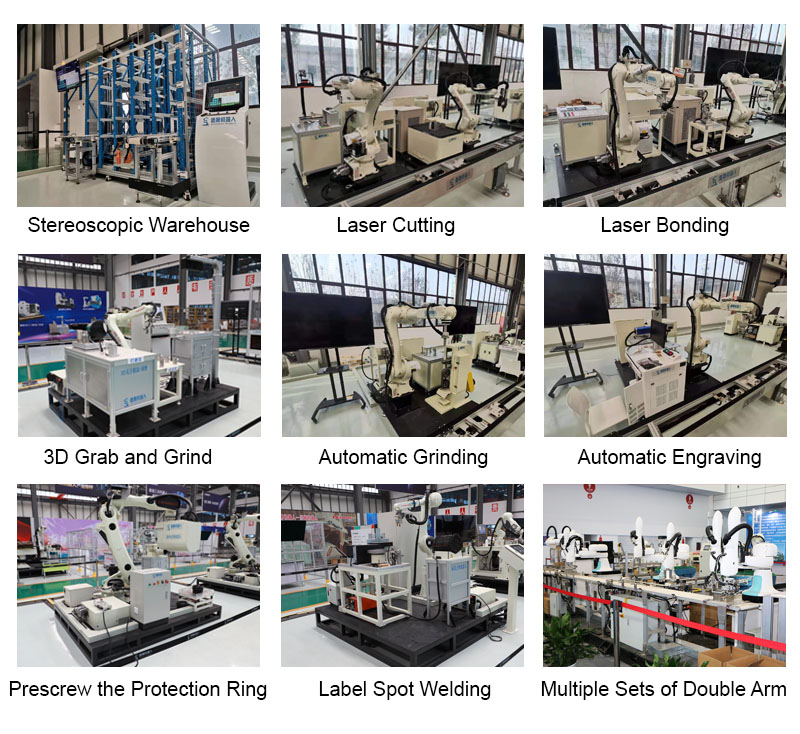

More Products: