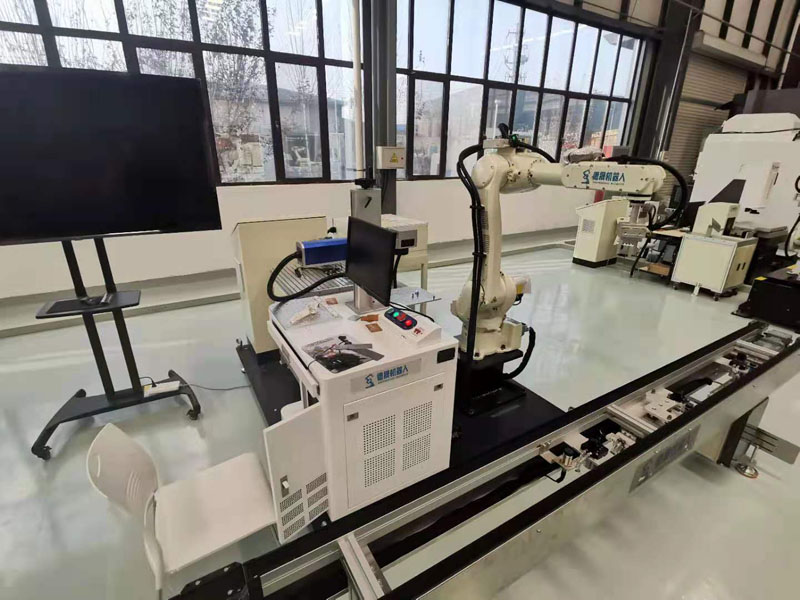

Automatic Welding Machines For Sale

1.The user-pleasant interface and programming of robots make a contribution to the convenience of use and efficient operation of current robotic systems.

2.Modern robots have a high degree of intelligence, permitting them to learn from and adapt to their surroundings, perform complex obligations, and engage seamlessly with human beings.

3. Robotic systems are renowned for his or her high manufacturing performance and safety, lowering hard work prices, growing productiveness and pleasant even as minimizing the threat of injuries to employees.

4. The smooth-to-manipulate nature of robot technology presents widespread economic benefits for companies by means of minimizing expenses whilst improving overall productivity.

Robotic welding machines and spot welding robots are excellent options available for sale if you are looking to invest in automatic welding machines. Robotic welding machines are ideal for high-volume production, performing repetitive tasks with greater accuracy and consistency as compared to manual welding. Spot welding robots, on the other hand, are perfect for welding small areas and are often used in the electronics and automotive industries. Though there may be a higher initial investment when considering the cost, it is important to remember that productivity and efficiency gained from automation will ultimately lead to long-term cost savings. The price of welding robots depends on several factors, including size, complexity, and brand. Research and compare models to find the best fit for your specific needs. With the implementation of robotic welding machines and spot welding robots, you can optimize your welding processes with advanced technology, improving your overall efficiency, quality, and competitiveness in the market.

PARAMETERS:

| Name | Welding robot | |||||||

| Type | Vertical joint 6 degrees | |||||||

| The main purpose | Laser Weld | |||||||

| specification | BR10iG-14 | |||||||

| Maxload weight | 10KG | |||||||

| Position repeatability | 0.05mm | |||||||

| Vibration | s4.9m/S | |||||||

| Body weight | 149KG | |||||||

| Maximum reach | 1566mm | |||||||

| Conditions | 0-45RC,10-80%RH(no condensation) | |||||||

| Protection class | Equivalent to lP65 | |||||||

| Installation | Ground, hoisting side mounting | |||||||

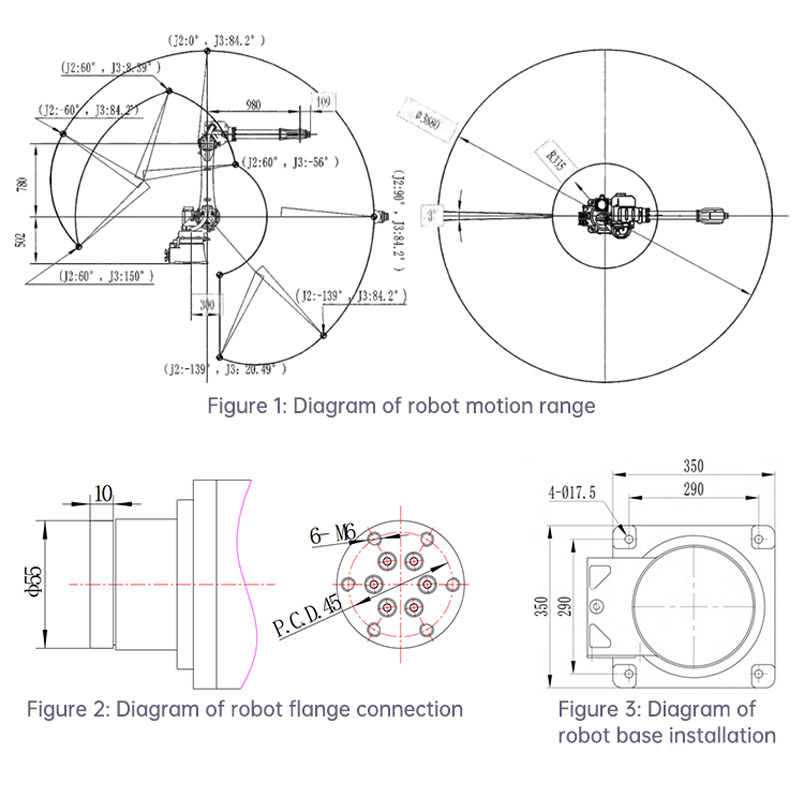

| Range Motion | basic axis | J1 | ±170° | Max Motion | basic axis | J1 | 173.6°/S | |

| J2 | +90°-160 | J2 | 138.8°/S | |||||

| J3 | +115°-90 | J3 | 198.3°/S | |||||

| arm axis | J4 | ±190° | arm axis | J4 | 288.1°/S | |||

| J5 | ±140° | J5 | 400°/S | |||||

| J6 | ±360° | J6 | 588.2°/S | |||||

DIMENSIONAL DRAWINGS:

robot CONTROLSYSTEM:

FEATRUES:

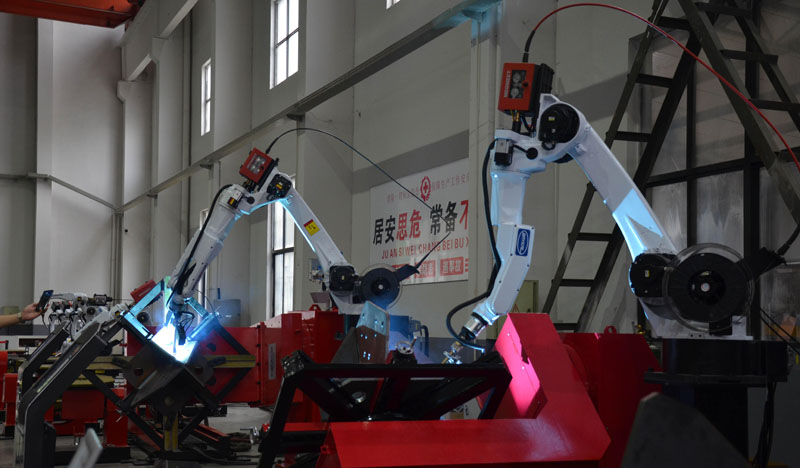

Arc welding robot is mainly divided into two types: electrode welding operation and non-electrode welding operation. It can carry out welding operation for a long time and ensure high productivity, high quality and high stability of welding operation.

The arc welding robot adopts ac servo pressure technology and high precision and high pressure reducer, which has top low velocity stability and high speed dynamic response.

Precise weld trajectory tracking technology, using laser sensor to achieve welding seam tracking in the process of welding, combined with visual sensor observation to obtain the residual deviation of welding seam tracking, can obtain the best welding quality under various conditions.

To coordinate and control the movement of the robot and the positioner, the relative attitude of the welding gun and the workpiece can be maintained, and the collision between the welding gun and the workpiece can be avoided.

APPLICATIONS:

Workstation field: that is, in the whole process of workpiece production, it is necessary to coordinate the operation of positioner and welding robot to realize automatic welding. This requires the movement of the positioner to be closely matched with the movement of the welding robot, so that the movement of the welding gun relative to the workpiece can not only meet the weld track but also meet the requirements of welding speed and the attitude of the welding gun.

Production line field: The welding robot production line is to connect the workpiece conveying line of a single site, and then form a production line. This manufacturing line maintains that each station can only use a set welding manner to finish the predetermined work; whilst there are more than one sites running, the welding robot will perceive the workpiece during the manufacturing line and routinely name out this system for welding.

Automobile parts field: Welding robots have been widely used in the automobile manufacturing industry, welding in automobile chassis, seats, mufflers and other aspects, especially in the automobile chassis welding production has been widely used, in this operation process, welding robots instead of the original arc welding operations, improve the welding quality, but also shorten the operation time.

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER

EXHIBITION:

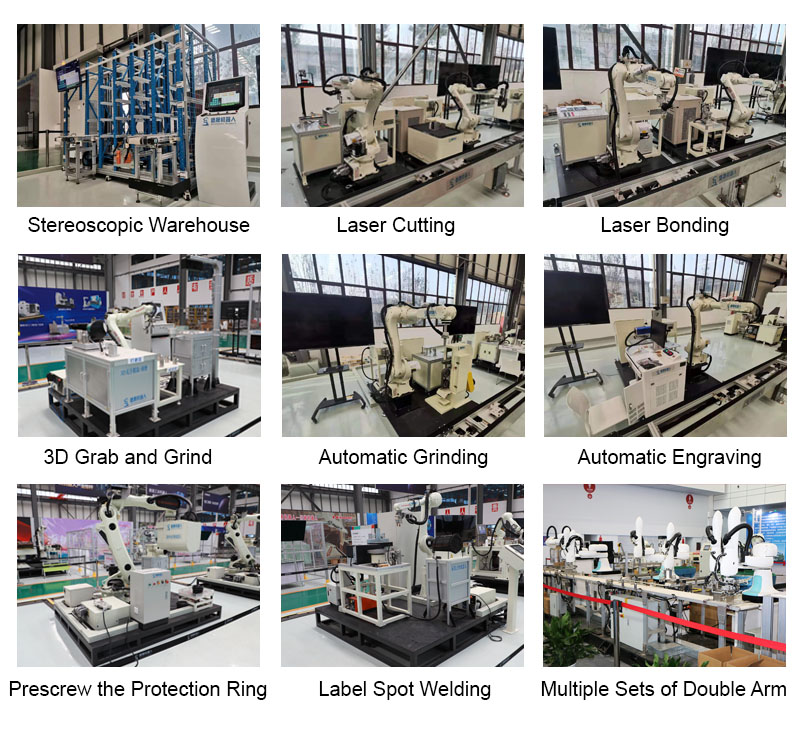

MORE PRODUCTS:

CONTACT US:

| Name | Welding robot | |||||||

| Type | Vertical joint 6 degrees | |||||||

| The main purpose | Laser Weld | |||||||

| specification | BR10iG-14 | |||||||

| Maxload weight | 10KG | |||||||

| Position repeatability | 0.05mm | |||||||

| Vibration | s4.9m/S | |||||||

| Body weight | 149KG | |||||||

| Maximum reach | 1566mm | |||||||

| Conditions | 0-45RC,10-80%RH(no condensation) | |||||||

| Protection class | Equivalent to lP65 | |||||||

| Installation | C | |||||||