Robots In Electronics Industry

Advantages ofRobots In Electronics Industry:

1,Efficiency: Robots in the electronics industry are capable of performing repetitive tasks with incredible speed and accuracy, leading to higher efficiency in the production process. This enables manufacturers to produce a higher volume of electronics products in a shorter amount of time, ultimately improving overall productivity.

2,Quality control: Robots can be programmed to perform precise and consistent actions, ensuring a high level of quality control in the production process. They are able to detect defects or abnormalities in electronic components, allowing manufacturers to identify and address any issues before the finished products are shipped to customers. This helps in reducing the number of defective products and improving customer satisfaction.

3,Safety: The electronics industry often involves working with delicate and potentially hazardous materials. Robots can be employed to handle these materials, reducing the risk of injuries to human workers. They can also be equipped with sensors and safety features to prevent accidents or damage to equipment, making the workplace safer for everyone involved.

Robots In Electronics Industry:

Robots in the electronics industry have revolutionized the production process. Companies like Kuka have introduced advanced robots such as the Kuka KR Agilus and Kuka Servo Robot, along with robotic handling systems. These innovations offer numerous benefits. The Agilus provides high speed and precision, enabling efficient manufacturing. Meanwhile, the Servo Robot ensures consistent quality control, reducing defects. Additionally, robotic handling systems improve workplace safety by handling delicate and hazardous materials. Overall, these robots have significantly enhanced productivity, efficiency, and product quality in the electronics industry.

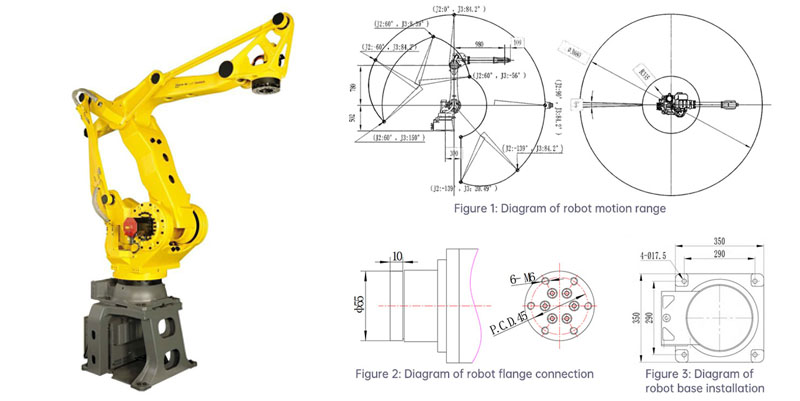

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

DIMENSIONAL DRAWINGS:

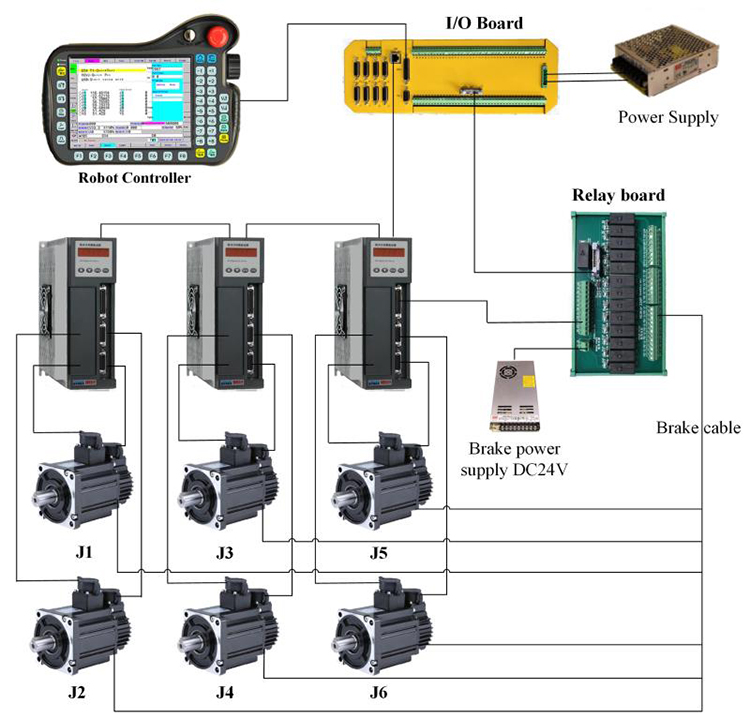

ROBOT CONTROLSYSTEM:

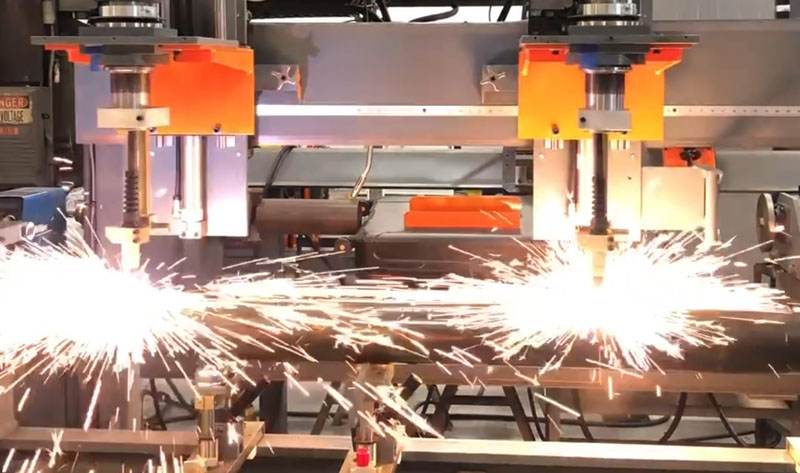

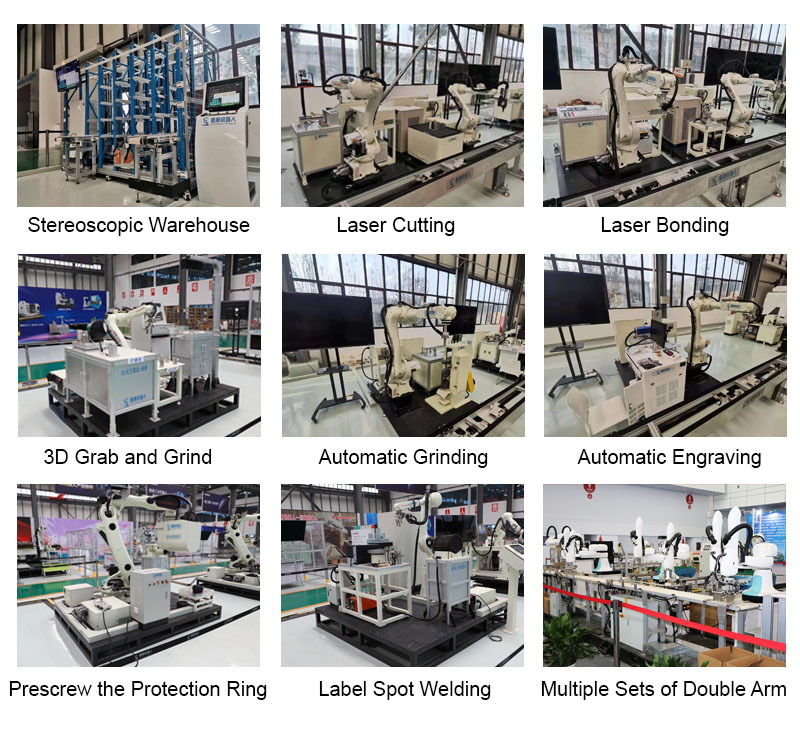

APPLICATIONS:

1,Assembly: Robots are commonly used in the electronics industry for assembly purposes. They are capable of precise and repetitive movements, allowing them to accurately assemble small electronic components and solder them onto circuit boards. This improves the efficiency of the assembly process and reduces the risk of human error.

2,Testing and Inspection: Robots are also utilized for testing and inspecting electronic products. They can be programmed to perform various tests, such as checking for connectivity, measuring voltage levels, and detecting defects or inconsistencies in the final products. This helps ensure the quality of the electronics before they are shipped to customers.

3,Packaging and Logistics: Robots are employed in the electronics industry for packaging and logistics tasks. They can efficiently pack finished products into boxes, apply labels, and stack them onto pallets for shipping. Robots are also utilized in warehouse operations, where they can autonomously navigate through storage areas and retrieve products for shipping or replenishment purposes. This streamlines the packaging and logistics process, reducing turnaround time and improving overall efficiency.

FEATURES:

1,Flexibility: Robots in the electronics industry are designed to be flexible and adaptable. They can be easily reprogrammed or reconfigured to perform various tasks and handle different types of electronic components. This allows manufacturers to quickly adjust their production processes to accommodate changes in product specifications or demand.

2,Precision: Robots in this industry are known for their high level of precision. They can perform intricate movements and delicate tasks with accuracy, ensuring the precise placement of components, soldering, and other assembly operations. This precision results in higher quality products and reduces the need for rework or repairs.

3,Integration with technology: Robots in the electronics industry are designed to seamlessly integrate with other technologies and systems. They can be connected to computer systems for real-time monitoring and data collection, allowing for improved process control and quality management. Additionally, robots can be equipped with vision systems, sensors, and artificial intelligence capabilities, enabling them to make intelligent decisions and adapt to changing production conditions. This integration enhances the overall efficiency and effectiveness of the production process.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

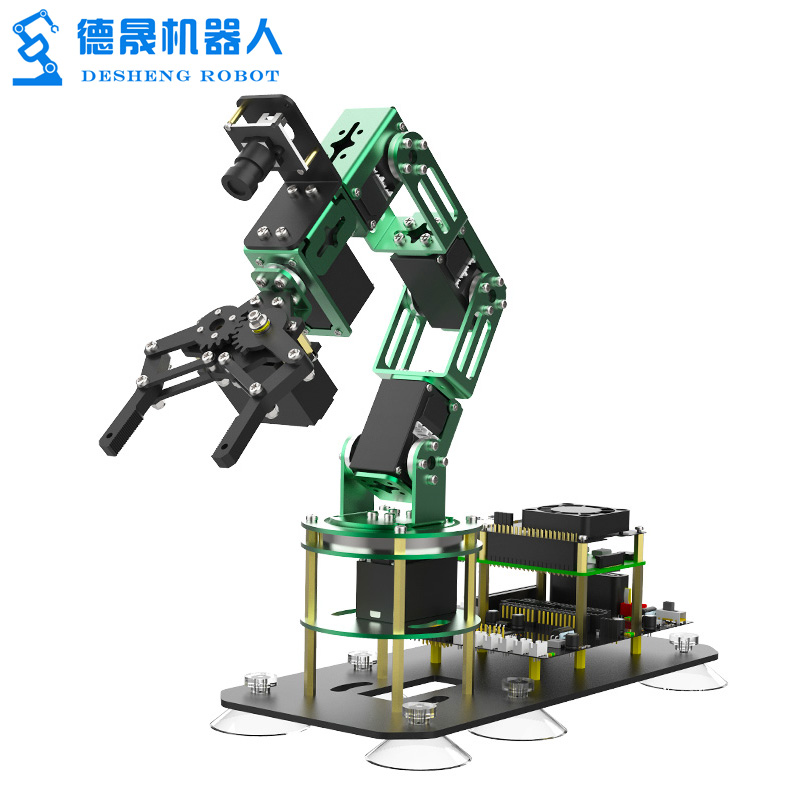

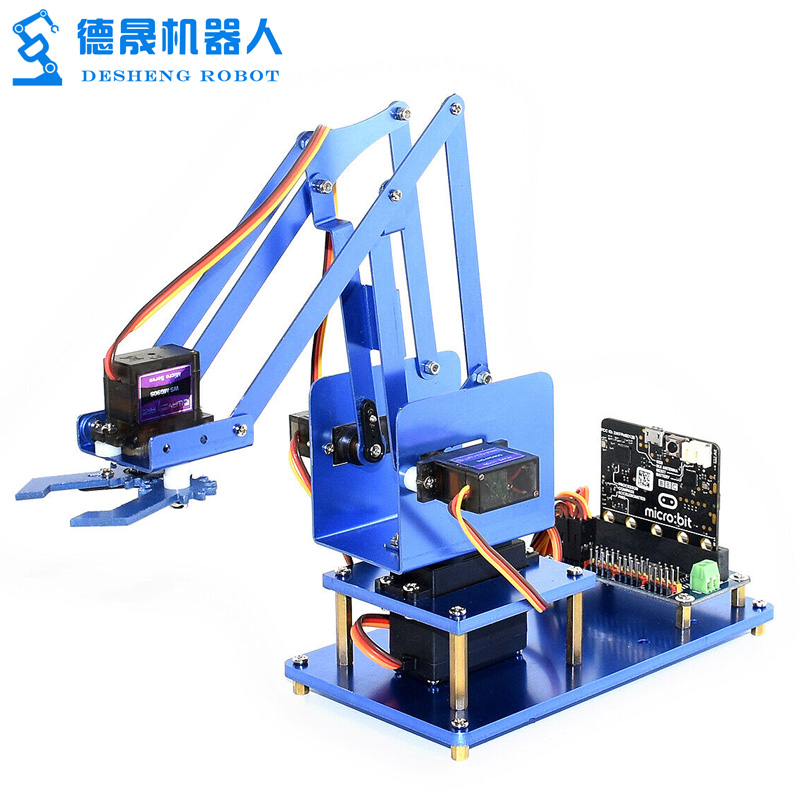

MORE PRODUCTS:

CONTACT US: