Leading Industrial Robotics Companies

Advantages of Leading Industrial Robotics Companies:

1,Increased productivity and efficiency: Industrial robotics systems offer the advantage of increased productivity and efficiency. Robots can work faster and for longer durations without experiencing fatigue or monotony, resulting in higher output and reduced processing time.

2,Improved accuracy and precision: Industrial robots are designed to perform tasks with high accuracy and precision, ensuring consistent quality and reducing errors. This leads to improved product quality and customer satisfaction.

3,Enhanced worker safety: Industrial robotics systems help in creating a safer work environment by automating hazardous and repetitive tasks. By removing human operators from potentially dangerous situations, robots minimize the risk of accidents and injuries, promoting a safer workplace.

Leading Industrial Robotics Companies:

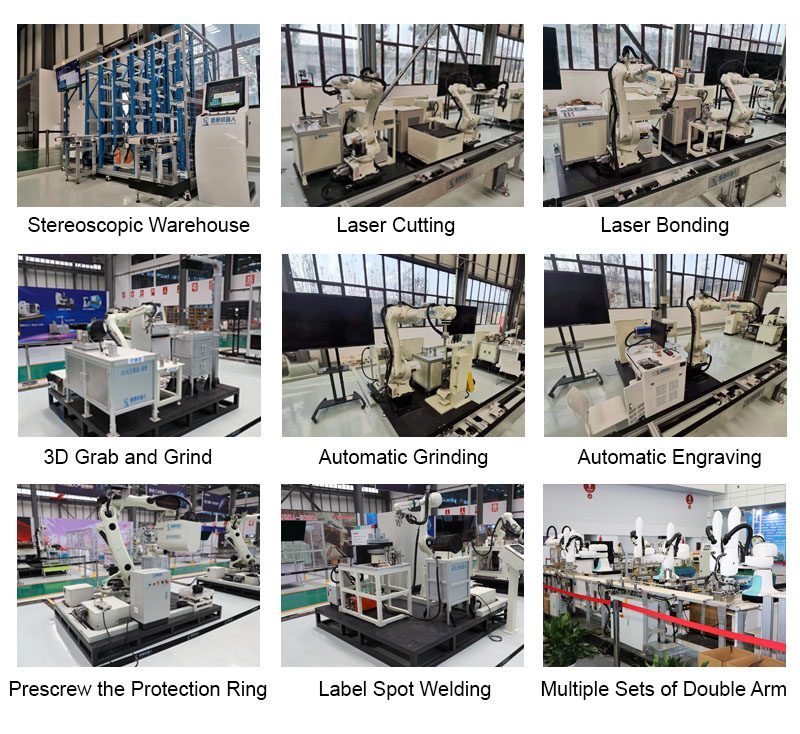

Leading industrial robotics companies, coupled with robotic process automation (RPA) companies, are transforming the manufacturing landscape. These companies, known for their innovative solutions, develop advanced robots capable of performing complex tasks with precision and efficiency. Integrated with RPA software, these robots automate repetitive processes, improving productivity and reducing errors. Enhancing this automation is the VersaView 6300P Industrial Monitor, offering a robust and user-friendly interface for monitoring and controlling industrial operations. Furthermore, automated guided vehicles, such as AMR material handling systems, revolutionize logistics by autonomously navigating through warehouses, optimizing efficiency, and reducing labor costs. Together, these technologies empower industries to boost productivity, streamline processes and meet the evolving demands of the modern manufacturing landscape.

PARAMETERS:

SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

Robot arm | Japanese Brand Robot | Fanuc | Kawasaki | |

German Brand Robot | KUKA | |||

Switzerland Brand | ||||

Main Performance | Speed Capacity | 8s per cycle | Adjust according to products and arrangement | |

Weight | About 8000kg | |||

Applicable Product | Cartons, cases,bags, | Containers,bottles,cans,buckets etc | ||

Power and Air | Compressed Air | 7bar | ||

Electric Power | 17-25 Kw | |||

Voltage | 380v | 3 Phases | ||

PLC | Siemens | |||

Frequency Converter | Danfoss | |||

Photoelectric Sensor | SICK | |||

Servo Motor | Panasonic | |||

Pneumatic Component | SMC | |||

Low-voltage Apparatus | Schneider | |||

Touch Screen | Schneider/Siemens | |||

Driving Motor | SEW | |||

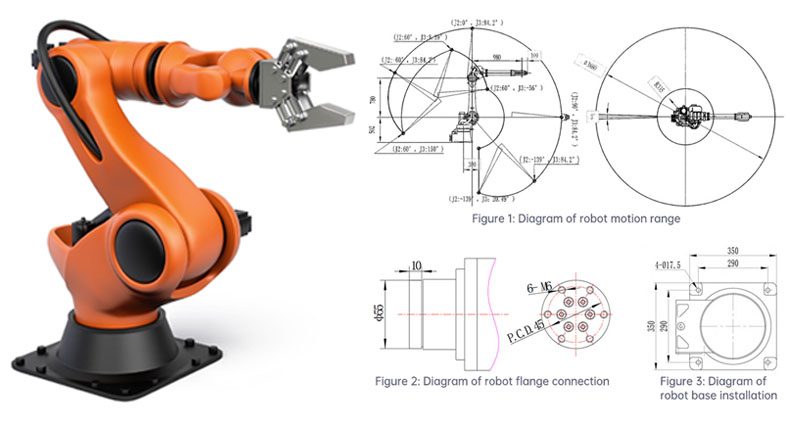

DIMENSIONAL DRAWINGS:

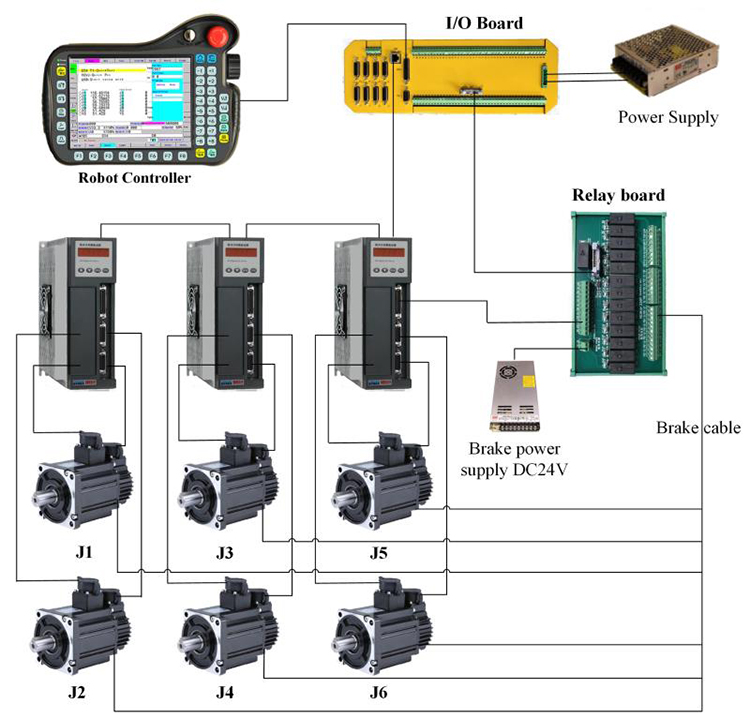

ROBOT CONTROLSYSTEM:

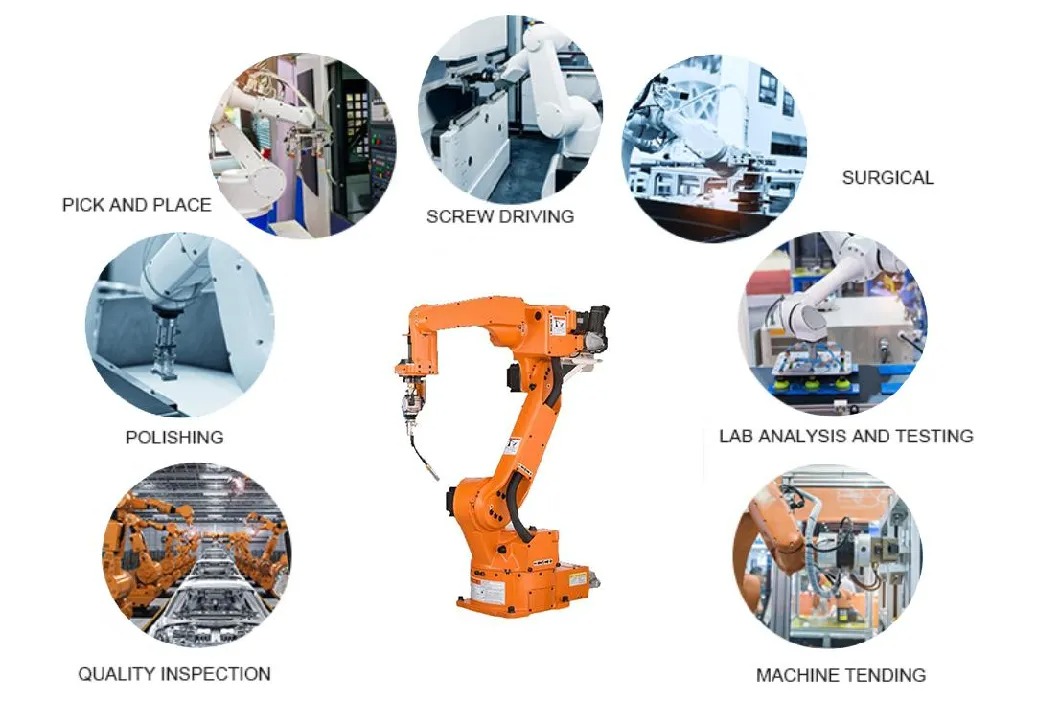

APPLICATIONS:

FEATURES:

1,Increased productivity and efficiency: Industrial robotics systems are known for their ability to significantly increase productivity and efficiency in various industries. They can work continuously and quickly, performing tasks at a much faster rate than human workers, leading to higher output and reduced production time.

2,Precise and accurate operations: Industrial robots are designed to perform tasks with a high level of precision and accuracy. They can execute repetitive movements with consistent accuracy, resulting in improved product quality and reduced errors in manufacturing processes.

3,Enhanced worker safety: Industrial robotics systems promote worker safety by automating hazardous and physically demanding tasks. By removing human operators from dangerous environments, robots minimize the risk of accidents and injuries, ensuring a safer workplace for employees.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: