Autonomous Robotic Construction System

Advantages of Autonomous Robotic Construction System:

1,Improved Safety: Autonomous Robotic Construction Systems provide a safer working environment by reducing the need for human workers to perform hazardous tasks. With their advanced sensors and algorithms, these robots can navigate and operate in dangerous conditions, minimizing the risk of accidents and injuries.

2,Enhanced Efficiency: These systems offer increased efficiency in construction projects. Autonomous robots can work around the clock, without the need for breaks or rest, leading to faster completion times. They can also optimize construction processes, reducing waste and improving overall project efficiency.

3,Precision and Accuracy: Autonomous Robotic Construction Systems excel in delivering precise and accurate results. With their advanced technologies and algorithms, these robots can perform tasks with impeccable precision, ensuring consistent quality and reducing the need for rework. This leads to improved project outcomes and customer satisfaction.

Autonomous Robotic Construction System:

Revolutionizing Industrial Robotics: Autonomous Construction, Mobile Welding, and Robotic Factory Automation

The industrial robotics landscape has witnessed groundbreaking innovations. Autonomous Robotic Construction Systems have transformed the construction industry, while the Biggest Industrial Robotics Companies continue to lead in technology development. Mobile Welding Robots offer enhanced flexibility and accessibility, while Robotic Factory Automation streamlines manufacturing processes. These advancements bring increased efficiency, safety, and productivity to a range of industries, shaping the future of automation.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

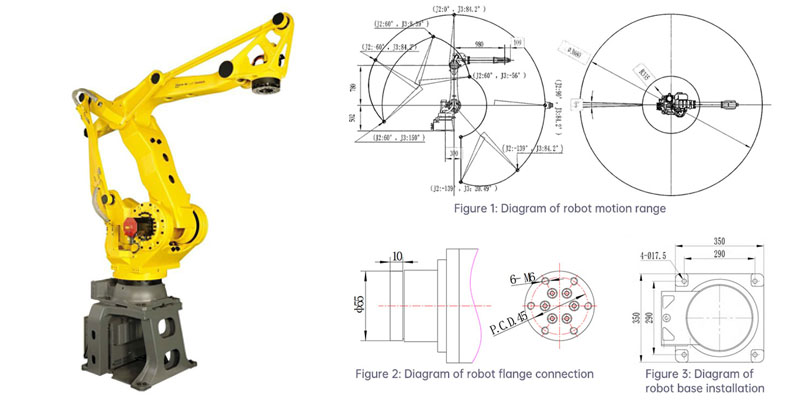

DIMENSIONAL DRAWINGS:

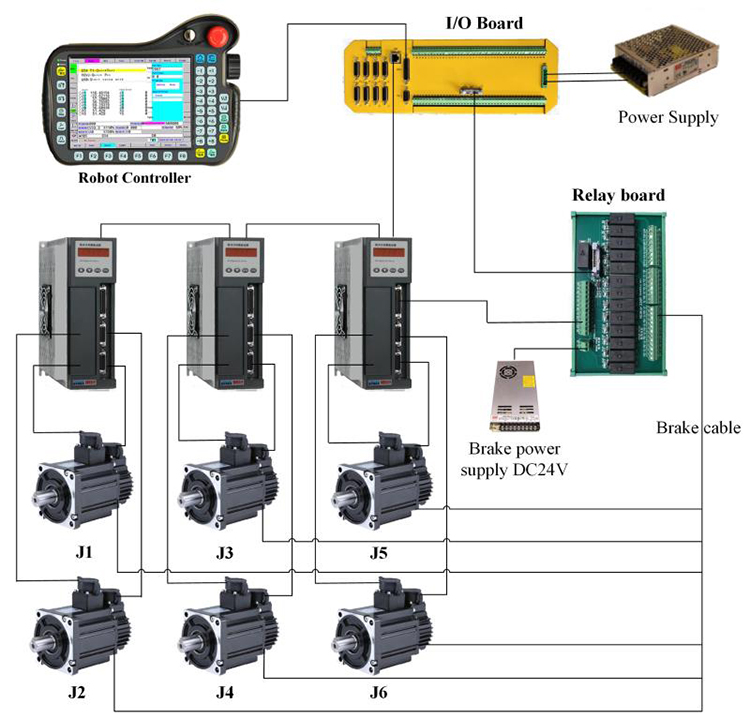

ROBOT CONTROLSYSTEM:

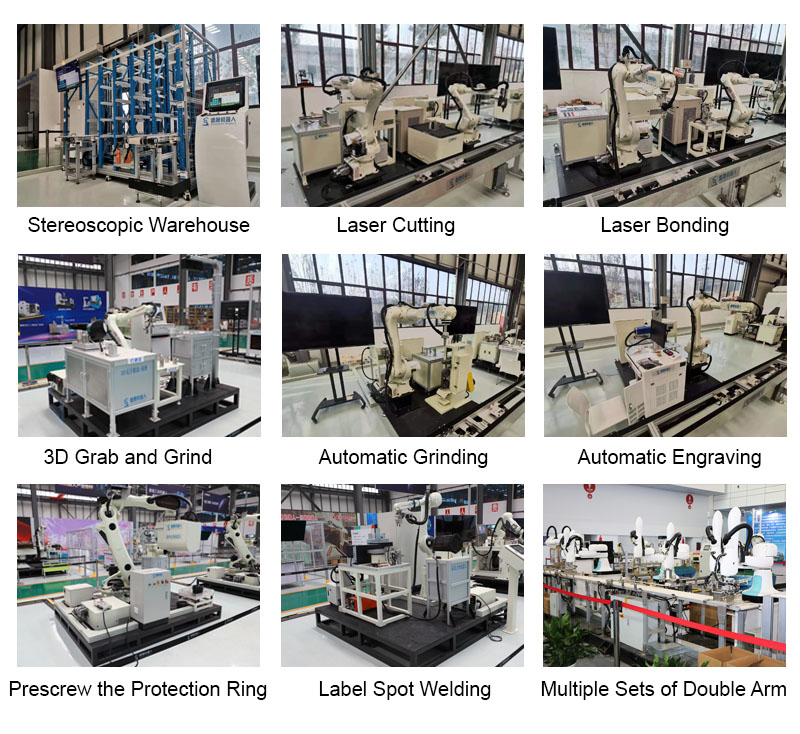

APPLICATIONS:

1,Construction Industry: Autonomous Robotic Construction Systems find extensive application in the construction industry. They can perform tasks such as site surveying, bricklaying, concrete pouring, and even 3D printing of structures. These robots operate autonomously, reducing the need for manual labor and improving construction efficiency, accuracy, and safety.

2,Infrastructure Development: These systems are also utilized in infrastructure development projects such as road construction, bridge building, and tunnel excavation. Their ability to work continuously, navigate complex terrains, and execute precise tasks makes them invaluable in speeding up construction processes and ensuring high-quality infrastructure.

3,Disaster Response and Recovery: Autonomous Robotic Construction Systems play a vital role in disaster response and recovery efforts. They can be deployed in areas affected by natural disasters to quickly rebuild and restore critical infrastructure. These robots assist in debris removal, rehabilitation, and rebuilding, minimizing human exposure to dangerous environments and expediting the recovery process.

FEATURES:

1,Efficiency: ARCS streamlines the construction process by automating various tasks, resulting in increased efficiency. It can perform repetitive tasks with precision and speed, reducing the time and effort required for construction projects. This allows for faster project completion and improved productivity.

2,Precision and Accuracy: ARCS utilizes advanced sensors and algorithms to ensure precise and accurate construction. It can measure and analyze data in real-time, making adjustments as needed to maintain accuracy throughout the construction process. This helps minimize errors and ensures high-quality construction outcomes.

3,Safety: Safety is a top priority in the construction industry, and ARCS enhances safety measures. By taking over hazardous tasks, such as heavy lifting or working at heights, ARCS reduces the risk of accidents and injuries to human workers. It is equipped with safety features like collision detection and emergency stop mechanisms, further enhancing the overall safety of construction sites.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: