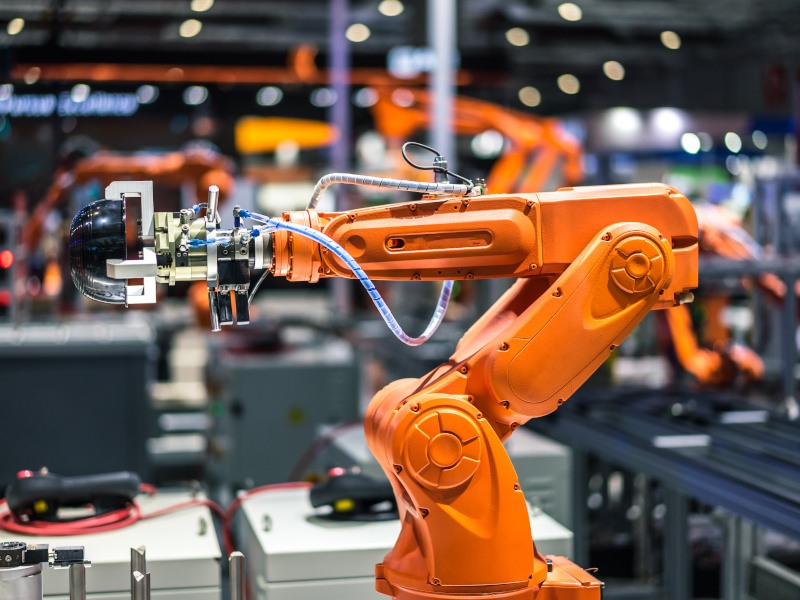

Advanced Robotics For Manufacturing

Advantages of Advanced Robotics For Manufacturing:

1. Increased productivity: Industrial robots can work continuously without getting tired or needing breaks, leading to higher productivity levels. They can also perform repetitive tasks with precision and consistency, reducing errors and improving overall efficiency.

2. Improved safety: By automating hazardous or dangerous tasks, industrial robots can help protect workers from potential injuries or accidents. They can handle tasks in environments that may be harmful to humans, such as high temperatures or toxic substances, ensuring a safer working environment.

3. Cost savings: Industrial robots can help reduce costs in various ways. They can operate at a higher speed, resulting in faster production cycles and reduced labor costs. Additionally, they can minimize material waste by ensuring accurate and precise movements. Overall, industrial robots offer a cost-effective solution for many manufacturing processes.

Advanced Robotics For Manufacturing:

Advanced Robotics For Manufacturing (ARM) is a cutting-edge technology that combines robotics and automation to revolutionize the manufacturing industry. With ARM, companies can enhance their production systems and integrate computer-controlled manufacturing processes.

Automation Production Systems And Computer Integrated Manufacturing (CIM) is another innovative approach that combines computer technology with manufacturing processes. CIM enables companies to streamline their production systems, reduce costs, and improve efficiency.

When it comes to the best automation companies, there are several industry leaders to consider. Companies like ABB, Fanuc, and KUKA are renowned for their expertise in robotics and automation. These companies provide state-of-the-art solutions that help businesses automate their manufacturing processes and increase productivity.

Robotics and automation also play a crucial role in the logistics industry. With the use of robots and automated systems, companies can optimize their warehouse operations, improve order fulfillment processes, and enhance overall supply chain management. This technology enables faster and more accurate handling of goods, leading to increased efficiency and customer satisfaction.

In conclusion, advanced robotics and automation technologies such as ARM and CIM are transforming the manufacturing industry. Companies can benefit from the expertise of top automation companies to enhance their production systems. Additionally, robotics and automation are revolutionizing the logistics industry, leading to improved efficiency in warehouse operations and supply chain management.

PARAMETERS:

SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

Robot arm | Japanese Brand Robot | Fanuc | Kawasaki | |

German Brand Robot | KUKA | |||

Switzerland Brand | ABB | |||

Main Performance | Speed Capacity | 8s per cycle | Adjust according to products and arrangement | |

Weight | About 8000kg | |||

Applicable Product | Cartons, cases,bags, | Containers,bottles,cans,buckets etc | ||

Power and Air | Compressed Air | 7bar | ||

Electric Power | 17-25 Kw | |||

Voltage | 380v | 3 Phases | ||

PLC | Siemens | |||

Frequency Converter | Danfoss | |||

Photoelectric Sensor | SICK | |||

Servo Motor | Panasonic | |||

Pneumatic Component | SMC | |||

Low-voltage Apparatus | Schneider | |||

Touch Screen | Schneider/Siemens | |||

Driving Motor | SEW | |||

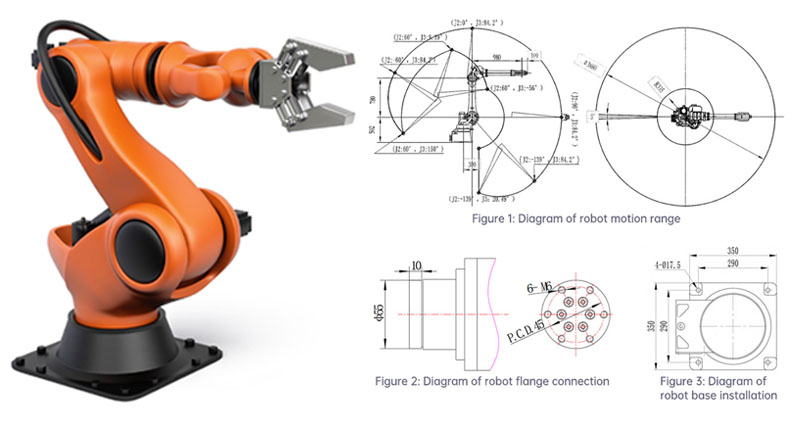

DIMENSIONAL DRAWINGS:

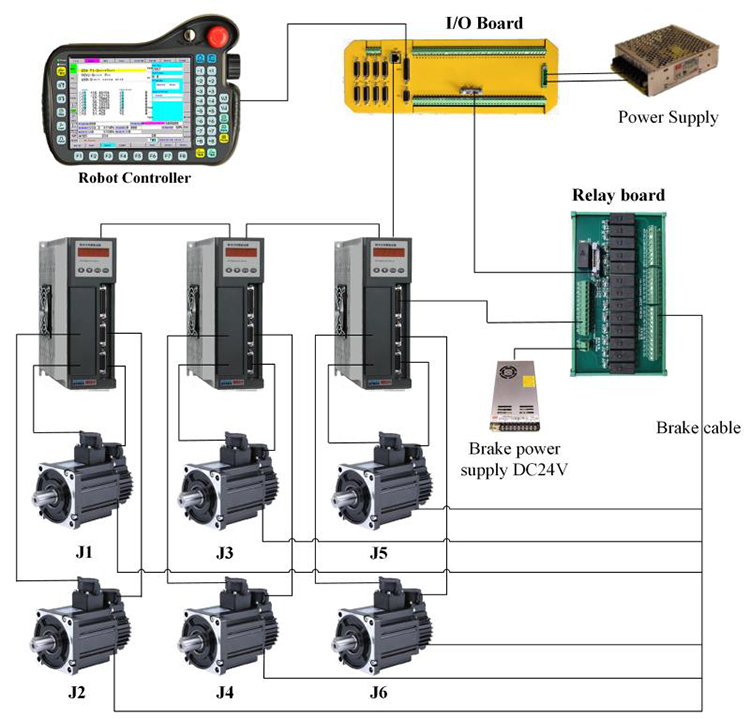

ROBOT CONTROLSYSTEM:

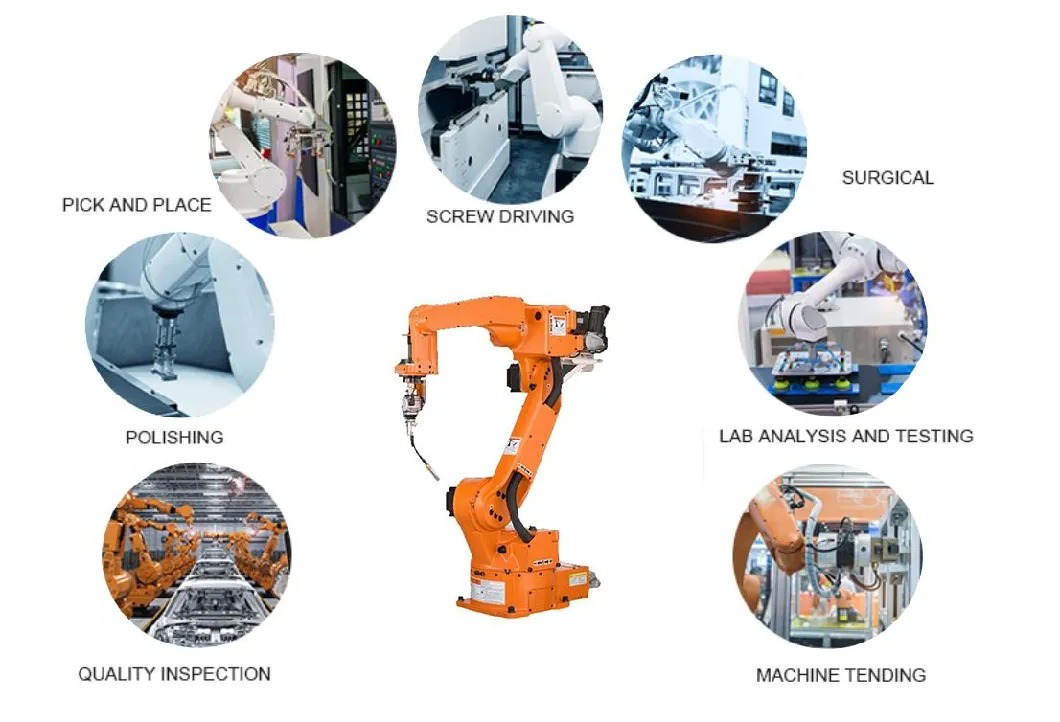

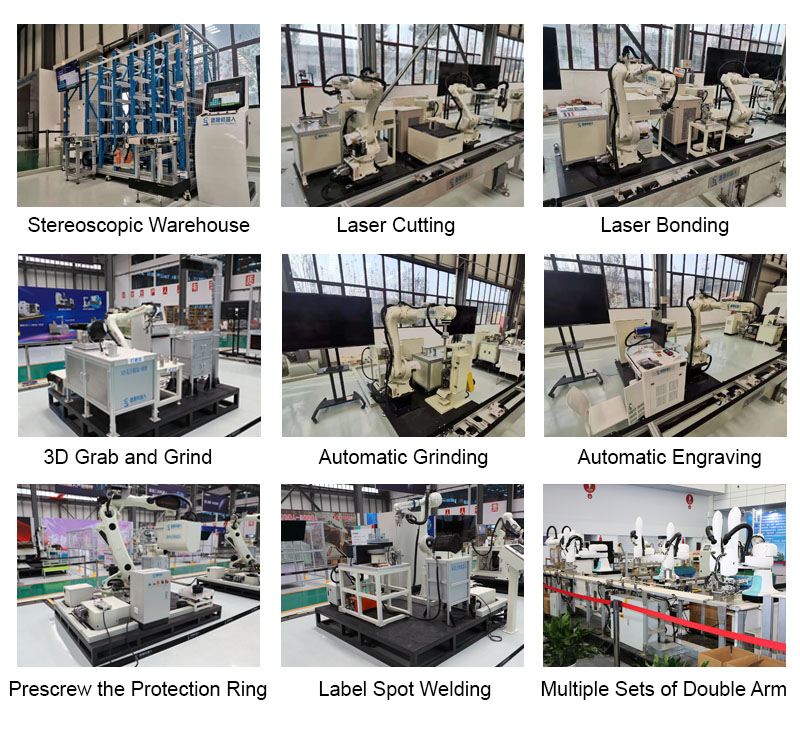

APPLICATIONS:

FEATURES:

1. High precision: Industrial robots are designed to perform tasks with high accuracy and precision. They can repeat the same movement or operation multiple times without any deviation, ensuring consistent quality in production processes.

2. Versatility: Industrial robots are programmable machines capable of performing a wide range of tasks. They can be easily reprogrammed and adapted to different applications, allowing manufacturers to achieve flexibility in their production lines.

3. Increased productivity: Industrial robots can work continuously without getting tired or needing breaks, resulting in increased productivity and efficiency. They can handle heavy loads, perform repetitive tasks, and work at a faster pace than human workers, leading to higher output levels in manufacturing processes.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: