Cobot Technology System

Advantages of Cobot Technology System:

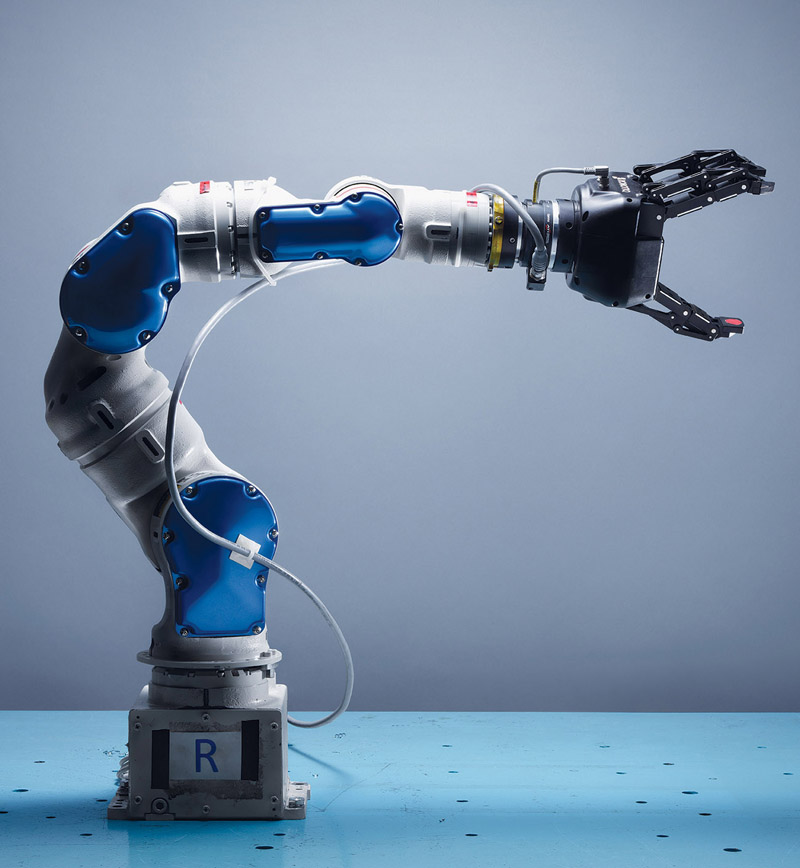

1,Increased Safety: Cobot Technology Systems prioritize safety in human-robot collaboration. With advanced sensors, such as force or torque sensors, and built-in safeguards, they can detect and react to unexpected human interactions or obstacles in their workspace. This ensures the safety of human operators and minimizes the risk of accidents or injuries.

2,Easy Programming and Flexibility: Cobot Technology Systems typically feature intuitive programming interfaces that require minimal coding knowledge. This ease of programming allows for quick deployment and adaptation to different tasks and environments. The systems often offer flexible, reconfigurable designs, enabling them to handle various applications and collaborate with different tools or attachments.

3,Enhanced Productivity and Efficiency: Cobot Technology Systems optimize workflow efficiency by automating repetitive or physically demanding tasks, thereby freeing up human workers for more skilled or creative tasks. The ability to work alongside humans without physical barriers or dedicated safety zones also facilitates better collaboration and communication between team members. This streamlined workflow and improved collaboration lead to increased productivity in various industries.

Cobot Technology System:

Cobot Technology Systems, such as those offered by Advanced Robotics For Manufacturing (ARM), are transforming industries with their human-cooperative robots and specialized solutions. These innovative systems are making strides in various sectors, including nuclear inspection.

The integration of Cobot Technology Systems in nuclear inspection robots has greatly improved the safety and efficiency of radioactive material monitoring and maintenance. These robots can autonomously navigate hazardous environments, collect data, and perform inspections, minimizing human exposure to radiation.

Thanks to ARM's expertise in advanced robotics, their Cobot Technology Systems enable seamless collaboration between humans and robots. The intuitive programming interface allows operators to easily program and control the robots, facilitating efficient and precise operations.

Cobot Technology Systems are not limited to nuclear inspection; they also find applications in manufacturing, healthcare, and other industries. By automating repetitive or physically demanding tasks, these systems enhance productivity and enable workers to focus on more complex and value-added activities.

In summary, Cobot Technology Systems, including those offered by Advanced Robotics For Manufacturing, are revolutionizing industries by providing human-cooperative robots. Their integration into nuclear inspection robots improves safety, while their application in various sectors enhances productivity and efficiency, leading to a brighter future for robotics and automation.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

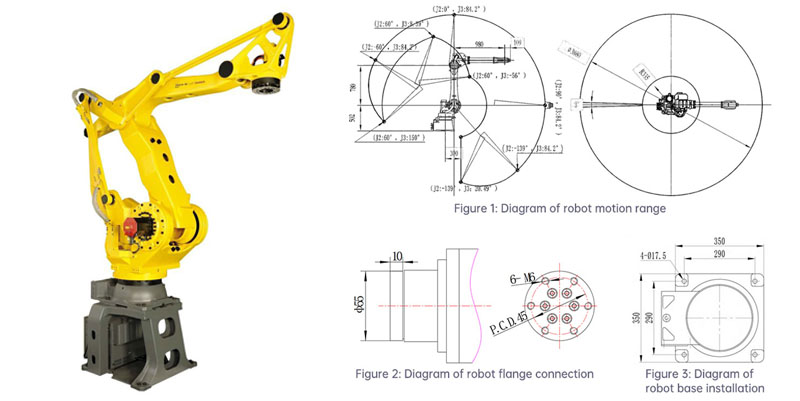

DIMENSIONAL DRAWINGS:

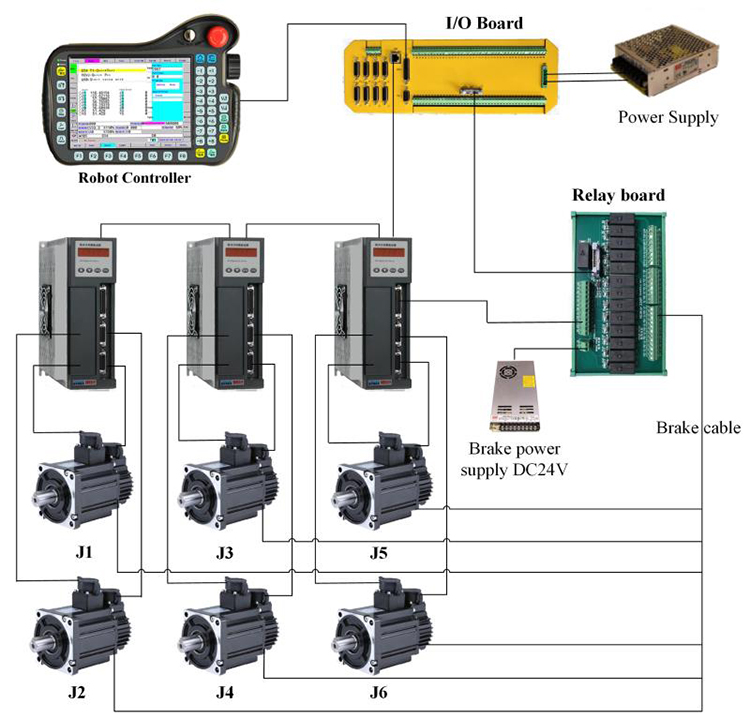

ROBOT CONTROLSYSTEM:

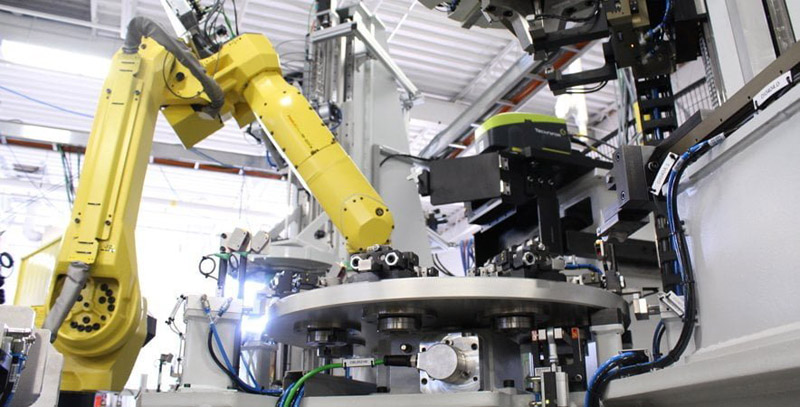

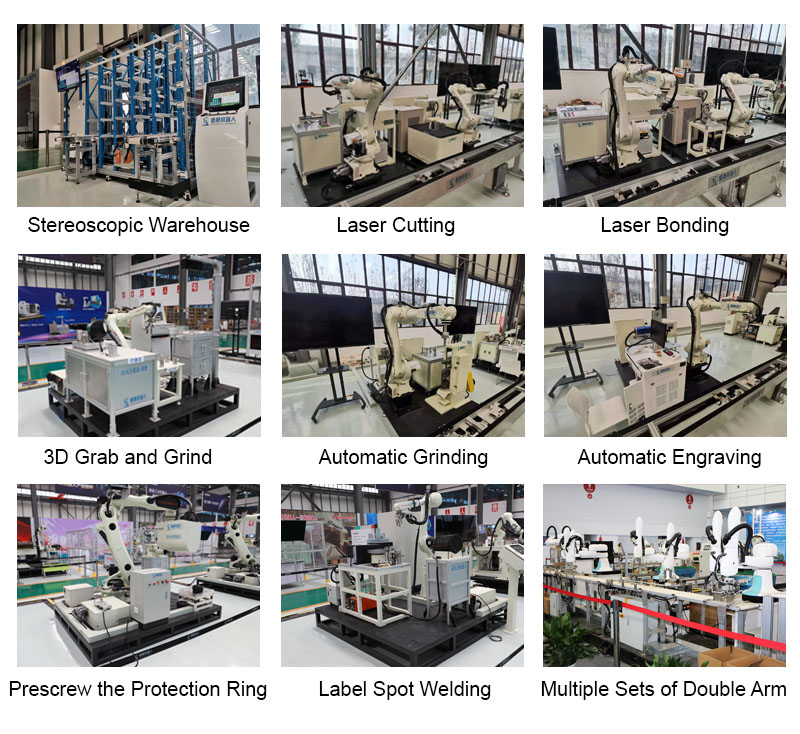

APPLICATIONS:

1,Collaborative assembly: Cobot technology allows for safe and efficient collaboration between humans and robots in assembly tasks. Cobots are equipped with sensors and advanced software that enable them to detect and respond to human presence, avoiding collisions and ensuring the safety of human operators. This collaborative approach enables faster and more accurate assembly processes.

2,Material handling: Cobots are commonly used in material handling tasks, such as picking and placing items on production lines or in warehouses. With their advanced sensing capabilities, cobots can accurately and carefully handle a variety of products, reducing the risk of damage or errors. They can also work alongside human operators, assisting with heavy lifting or repetitive tasks, improving productivity and reducing the risk of injuries.

3,Quality control and inspection: Cobots can be programmed to perform quality control and inspection tasks, ensuring product accuracy and consistency. With the use of cameras, sensors, and machine vision technology, cobots can detect defects or anomalies in products, perform measurements, and conduct other quality assurance checks. This helps to improve product quality, reduce waste, and streamline the inspection process.

FEATURES:

1,Safety features: Cobot technology systems are designed with a strong emphasis on safety. They are equipped with sensors and software that enable them to detect human presence and automatically stop or slow down their movements to prevent collisions. Additionally, they have soft and rounded edges to minimize the risk of injury if contact does occur.

2,Easy programming and reconfiguration: One of the key features of cobot technology systems is their user-friendly programming interfaces. They are designed to be easily programmable by non-experts, allowing operators to quickly and intuitively teach the cobots new tasks or modify existing ones. This flexibility enables the cobots to be quickly reconfigured for different applications, optimizing their use in a dynamic production environment.

3,Adaptive and collaborative capabilities: Cobots are designed to work alongside humans, rather than as standalone machines. They have adaptive capabilities that allow them to adjust their movements and forces based on the interaction with humans. This collaborative approach allows cobots to assist humans in tasks that require strength, precision, or endurance, improving productivity and ergonomics while ensuring the safety of the operators.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: