Type Of Industrial Robot

Advantages of Type Of Industrial Robot:

The advantages of Type Of Industrial Robot, including Industry Robot, labeling robot, and automatic label spot welding robot, are as follows: Firstly, they can perform highly repetitive, monotonous, and time-consuming work, which increases efficiency and productivity. Secondly, due to the amount of time machines can run continuously, with minimal downtime, the output of productivity is increased, benefiting Scara Robot Applications, Cartesian Robot Control System, and advancements in articulated robots. And lastly, using an industrial robot control system ensures the safe execution of hazardous or dangerous tasks, providing a safer working environment in the Industrial setting.

Type Of Industrial Robot:

Industrial robots, including Industry Robot, labeling robot, and automatic label spot welding robot, have made significant advancements in recent years through Scara Robot Applications, Cartesian Robot Control System, and enhancements in articulated robots. These cutting-edge technologies offered numerous benefits, such as improved efficiency, productivity, accuracy, and safety in the industrial setting.

The Industry Robot and labeling robot can automate repetitive tasks in industrial production lines, enabling faster and more efficient processes with minimal downtime. Meanwhile, the Scara Robot Applications and Cartesian Robot Control System offer precise task execution, making them well-suited for manufacturing and assembly operations. The advancements in articulated robots, on the other hand, have led to more complex and sophisticated technologies with greater dexterity and flexibility.

Overall, these developments in industrial robotics have enabled companies to streamline production and reduce costs while providing a safer and more efficient work environment. With the potential for further innovation and progress, the future of industrial robotics looks promising.

PARAMETERS:

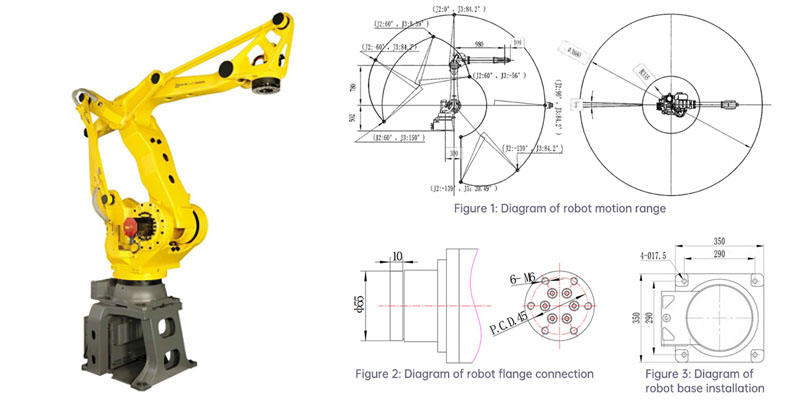

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

DIMENSIONAL DRAWINGS:

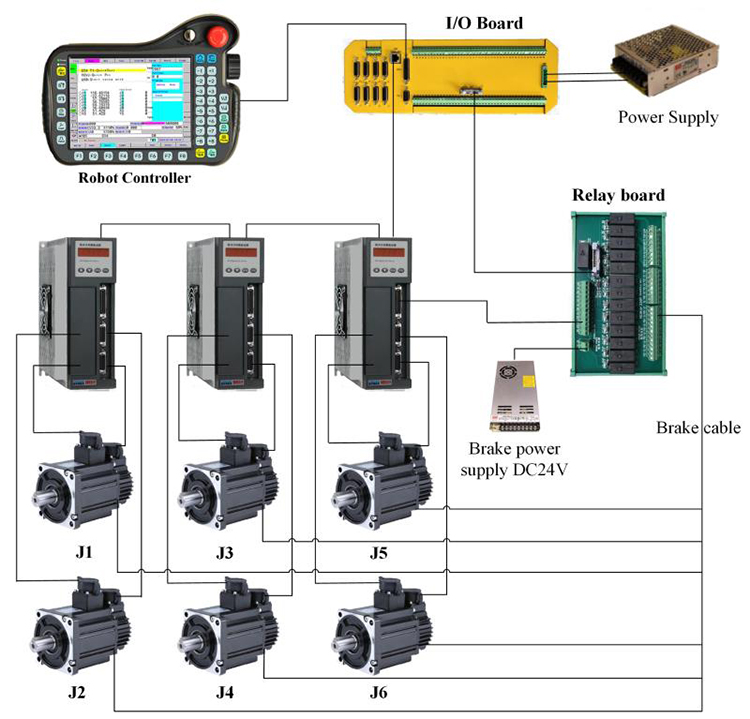

ROBOT CONTROLSYSTEM:

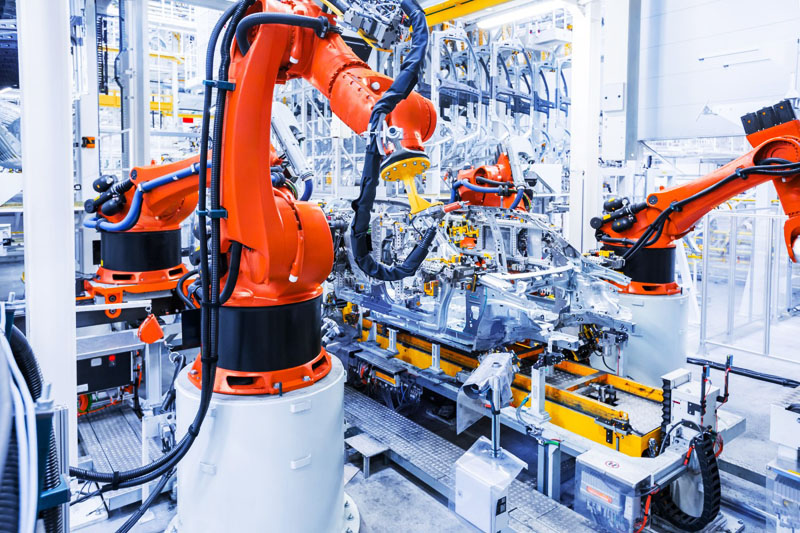

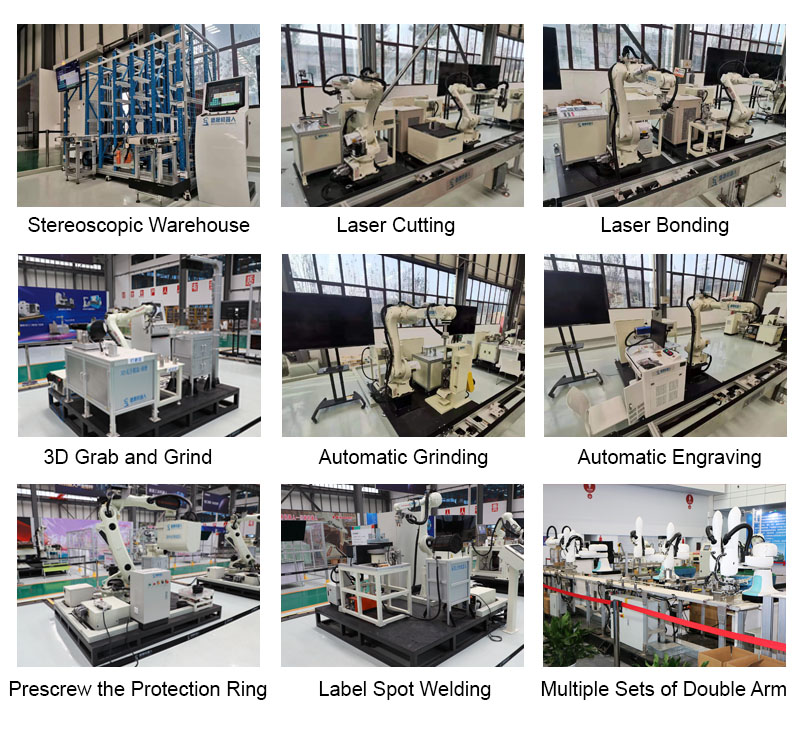

APPLICATIONS:

1,Manufacturing: Industrial robots are widely used in manufacturing and assembly lines to automate repetitive tasks and increase efficiency. They can handle heavy loads and are programmed to perform specific tasks with precision and accuracy, making them essential in the production of goods.

2,Healthcare: Industrial robots are also increasingly being used in the healthcare industry for a wide range of applications. For instance, they can be programmed to perform surgical procedures with extreme precision, and they can be used to help patients with physical therapy and rehabilitation.

3,Agriculture: The use of industrial robots is also gaining popularity in agriculture. They can be used for crop monitoring, harvesting, and processing. As the agricultural industry continues to evolve, industrial robots will increasingly become a vital tool to increase productivity and efficiency while lowering costs.

Overall, the diverse applications of industrial robots are a reflection of their versatility and their ability to improve efficiency, precision, accuracy, and safety across various industries.

FEATURES:

1,Increased Efficiency and Productivity: Industrial robots can automate repetitive tasks, significantly increasing productivity and efficiency levels. They can work non-stop with minimal downtime, ensuring consistent output, and predictable performance.

2,Enhanced Precision and Accuracy: Industrial robots can operate with high precision and accuracy, which is not always possible with human workers. They can complete tasks with minimal margin of error and execute them at an exact, repeatable level.

3,Improved Safety: Industrial robots can be programmed to handle hazardous and dangerous tasks, reducing the risks of workplace accidents, occupational hazards, injuries, and fatalities. This leads to a safer work environment for employees.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: