Industrial Robot Control System

Advantages of Industrial Robot Control System:

1,Enhanced Precision: The Industrial Robot Control System provides superior precision and accuracy in controlling robotic movements. With advanced algorithms and sensors, it enables precise positioning and manipulation, ensuring consistent and exact execution of tasks.

2,Improved Efficiency: This control system optimizes the performance of industrial robots, resulting in enhanced efficiency. It allows for faster and smoother operations, reducing cycle times and increasing productivity. By minimizing downtime and maximizing output, it helps businesses achieve higher levels of efficiency in their manufacturing processes.

3,Flexibility and Adaptability: The Industrial Robot Control System offers flexibility and adaptability to accommodate changing production requirements. It enables quick and seamless reprogramming of robots, allowing them to be easily redeployed for different tasks or workflows. This flexibility enhances operational agility, enabling businesses to respond swiftly to market demands and optimize their manufacturing capabilities.

Industrial Robot Control System:

The Industrial Robot Control System, such as the Mitsubishi SCARA robot and 5-axis robots, offers numerous advantages in various applications. These robots are known for their precise control and versatility, allowing for seamless integration into industrial processes. Additionally, they offer increased efficiency, reducing production times and costs. When it comes to wall painting, the price of the robot depends on factors such as size, features, and application requirements. However, the long-term benefits outweigh the initial investment, with increased speed, accuracy, and safety. Overall, the Industrial Robot Control System empowers industries with advanced automation capabilities, enhancing productivity and quality across a range of applications.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

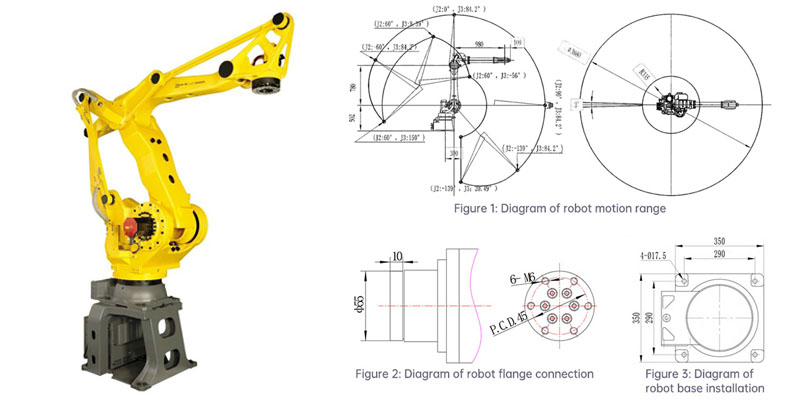

DIMENSIONAL DRAWINGS:

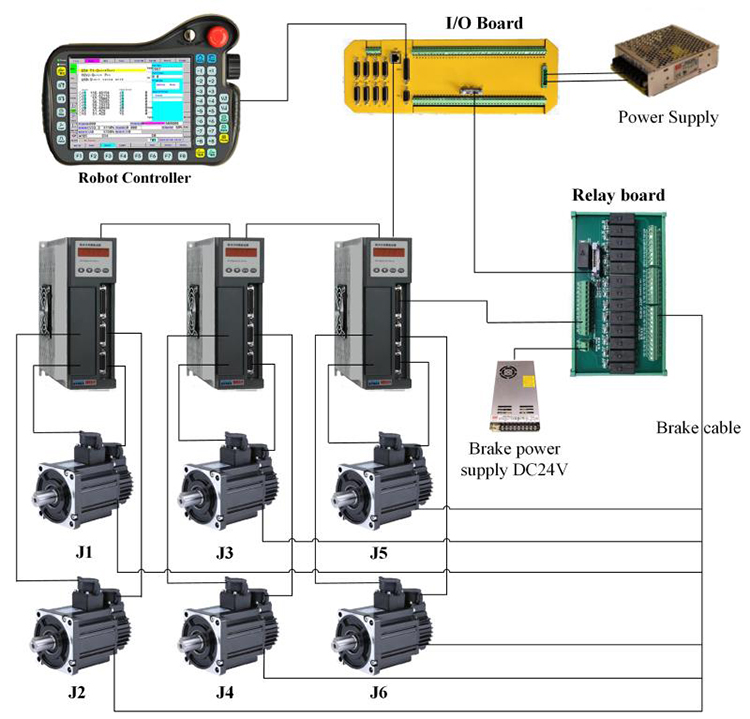

ROBOT CONTROLSYSTEM:

APPLICATIONS:

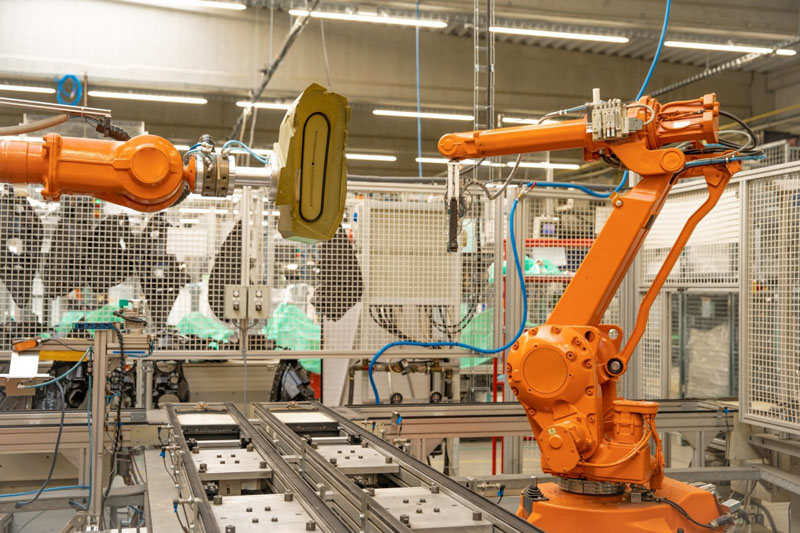

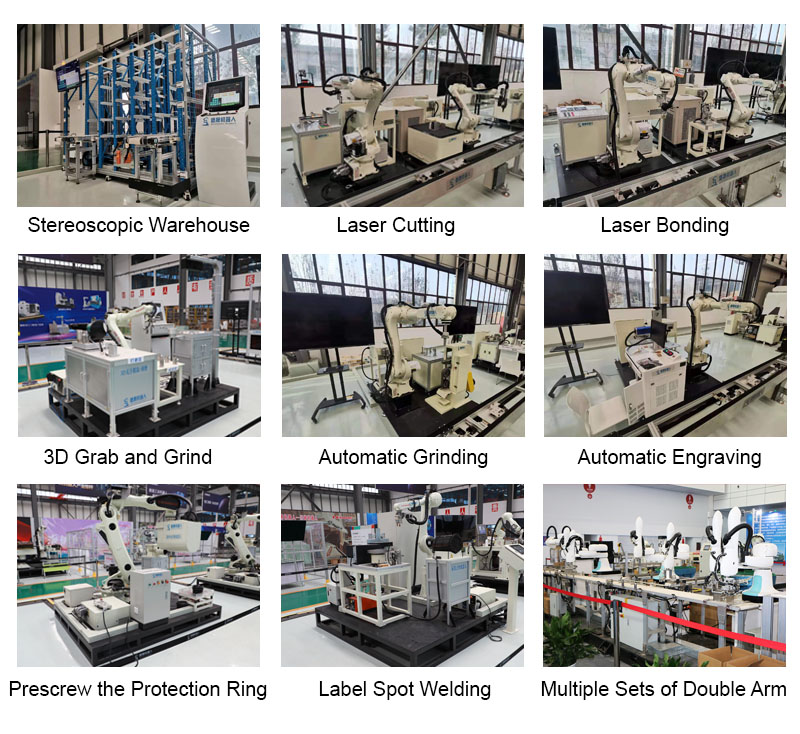

1,Manufacturing and Assembly: The Industrial Robot Control System finds extensive application in manufacturing and assembly processes. It enables precise and efficient handling of materials, components, and products. With their ability to perform repetitive tasks with great accuracy and speed, these control systems streamline production lines and improve overall productivity.

2,Welding and Cutting: Another prevalent application of the Industrial Robot Control System is in welding and cutting operations. These control systems provide precise control over robotic arms, allowing for consistent and high-quality welds or cuts. Whether it's in automotive, aerospace, or other industries requiring metal fabrication, these control systems ensure efficient and reliable results.

3,Inspection and Quality Control: Industrial Robot Control Systems are also utilized for inspection and quality control purposes. Equipped with advanced sensors and cameras, these systems enable robots to accurately inspect and measure products, components, or materials. This ensures adherence to quality standards and minimizes the chances of defects or faulty products reaching the market.

FEATURES:

1,Precision and Accuracy: The Industrial Robot Control System is designed to provide exceptional precision and accuracy in controlling robotic movements. It ensures that robots can perform tasks with high repeatability, resulting in consistent and precise outcomes.

2,Flexibility and Programmability: One of the key features of the Industrial Robot Control System is its flexibility and programmability. It allows for easy reprogramming and adaptation of robot movements and tasks, enabling quick changes to production requirements or workflow adjustments.

3,Safety and Reliability: The Industrial Robot Control System prioritizes safety in its design, incorporating various safety features and protocols to protect both the operators and the work environment. These systems are equipped with collision detection sensors, emergency stop functions, and other safety measures to ensure safe operation. Additionally, they offer reliability and stability, minimizing the chances of system failures or malfunctions.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: