Palletizing Robot Price

Advantages of Palletizing Robot Price:

1,Cost Savings: Palletizing robots offer significant cost savings compared to traditional manual labor. By automating palletizing processes, companies can reduce labor costs and minimize the risk of human errors, leading to improved operational efficiency and increased productivity.

2,Increased Productivity: Palletizing robots can work tirelessly, without the need for breaks or shifts, resulting in a significant increase in productivity. These robots can handle heavy loads and perform repetitive tasks with consistent precision and speed, allowing businesses to meet production demands more efficiently.

3,Improved Workplace Safety: Palletizing robots enhance workplace safety by reducing the risk of injuries associated with manual palletizing operations. These robots are equipped with advanced safety features, such as sensors and protective barriers, ensuring a safe working environment for employees. By minimizing manual handling, companies can mitigate the risk of workplace accidents and create a safer work environment overall.

Palletizing Robot Price, Cobot UR10 Price, Nuclear Inspection Robot, and Robots in the Steel Industry are transforming industries with their cost-effective automation solutions. Palletizing robots offer efficient handling at competitive prices, while UR10 cobots provide versatility at an affordable cost. Nuclear inspection robots ensure safety and accuracy in hazardous environments, though the pricing may be higher due to advanced technology. Robots in the steel industry enhance productivity, reduce errors, and improve workplace safety. With varying price ranges, these robots prove to be valuable investments, offering exceptional benefits and driving industry advancements.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

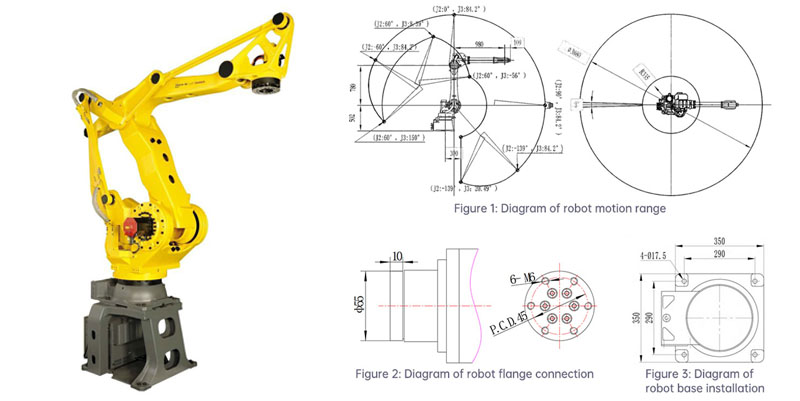

DIMENSIONAL DRAWINGS:

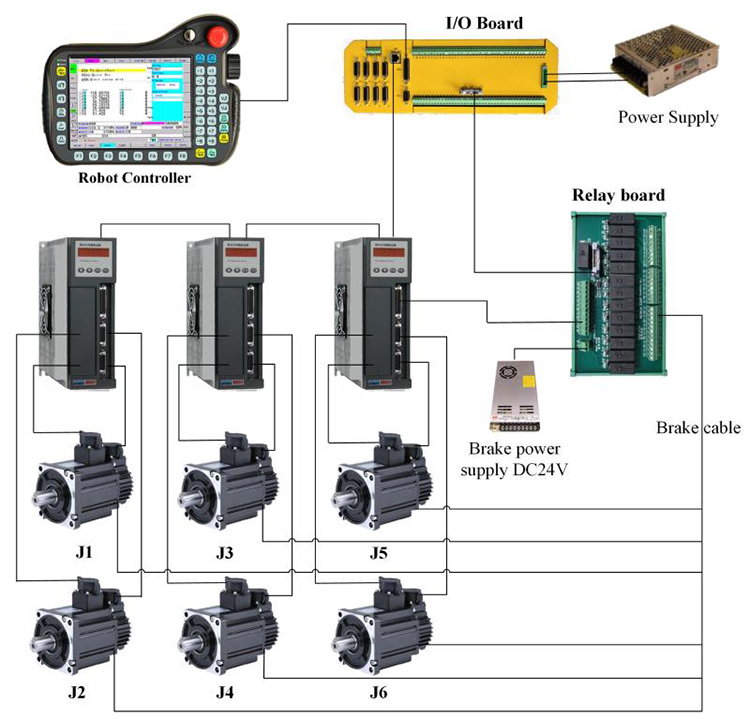

ROBOT CONTROLSYSTEM:

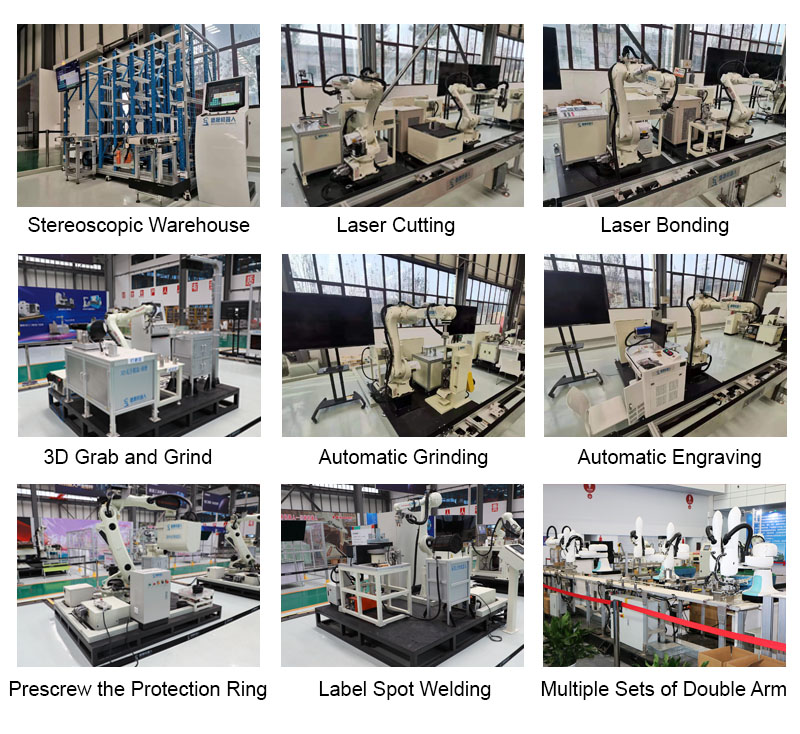

APPLICATIONS:

1,Manufacturing Industry: Palletizing robots are widely used in the manufacturing industry for automating the palletizing process. They can efficiently stack and arrange products on pallets, eliminating the need for manual labor. This application is commonly seen in industries like food processing, pharmaceuticals, and consumer goods manufacturing.

2,Logistics and Warehousing: Palletizing robots are also extensively used in the logistics and warehousing sectors. They play a crucial role in streamlining the loading and unloading of goods, optimizing space utilization, and ensuring precise stacking of pallets. By automating these tasks, companies can significantly improve efficiency and reduce the risk of errors during product handling.

3,Distribution Centers: Distribution centers rely on palletizing robots to handle large volumes of products and organize them for shipment. These robots can sort, stack, and arrange products based on predefined patterns, allowing for quicker and more accurate order fulfillment processes. The use of palletizing robots in distribution centers helps streamline operations, minimize labor costs, and enhance customer satisfaction with timely and error-free deliveries.

FEATURES:

1,Cost-effectiveness: Palletizing robots offer a cost-effective solution for automating the palletizing process. Compared to manual labor, they provide higher efficiency and productivity, reducing overall costs in the long run. The initial investment in a palletizing robot can be recouped through improved operational efficiency and reduced labor expenses.

2,Versatility: Palletizing robots are designed to handle a wide range of products, including boxes, bags, crates, and containers. They can adapt to various shapes, sizes, and weights, making them highly versatile. With programmable options, palletizing robots can be easily reconfigured to accommodate different product types and stacking patterns, providing flexibility in handling diverse product lines.

3,Precision and Accuracy: Palletizing robots offer precise and accurate stacking of products on pallets. Equipped with advanced sensors and vision systems, they can ensure proper alignment and placement of products, minimizing the risk of errors and damage during transportation. This precision also enables optimal space utilization, maximizing pallet capacity and reducing shipping costs.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: