Industrial Robot Arm

Advantages of Industrial Robot Arm:

1,Versatility: Industrial robot arms, including precision cylindrical robotic systems, labeling robots, and other automation robotics technologies, are incredibly versatile and can be programmed to perform a wide range of tasks, from assembly and packaging to welding and material handling.

2,Improved Efficiency and Productivity: Advanced automation robotics systems, such as automated manufacturing robotics systems, are designed to work tirelessly and at a consistently high level of performance. Industry robots can work around the clock to maximize productivity and output.

3,Enhanced Precision and Accuracy: Manufacturing robots are purpose built to perform their duties with a high level of precision and accuracy. With advanced sensors and control systems, industrial robot arms can ensure consistent, high-quality output while reducing the potential for human error.

Industrial robot Arm:

Industrial Robot arms are an essential part of the modern manufacturing landscape. Advanced automation robotics systems, including precision cylindrical robotic systems, automated manufacturing robotics systems, industry robots, and labeling robots, offer many benefits to organizations looking to maximize efficiency and productivity.

At the heart of the appeal of industrial robot arms is their versatility. These machines can be programmed to perform a wide range of tasks, from welding and material handling to assembly and packaging. This versatility makes them ideal for organizations with complex or varied needs.

Moreover, industrial robot arms can work around the clock, maximizing productivity while reducing the potential for human errors. They are also purpose-built to perform their duties accurately and precisely, ensuring that output quality remains at a consistently high level.

Finally, the benefits of industrial robot arms go beyond their direct impact. They can enhance worker safety and job satisfaction by automating the most dangerous, dirty, or repetitive tasks. In conclusion, advanced automation robotics systems, such as precision cylindrical robotic systems, automated manufacturing robotics systems, industry robots, and labeling robots, are increasingly essential for modern manufacturing organizations looking to thrive in the 21st century.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

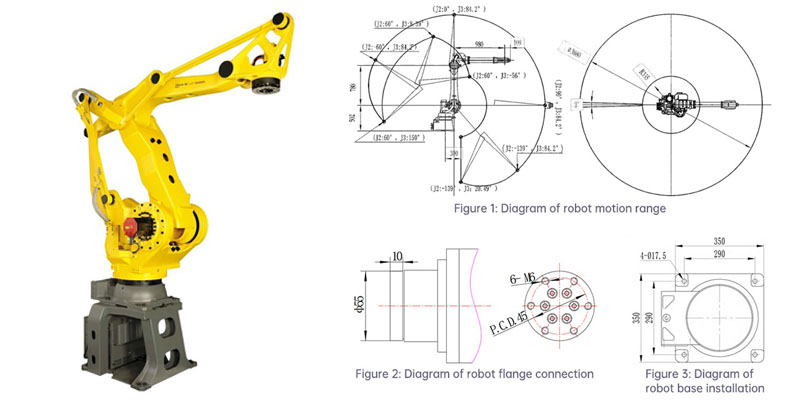

DIMENSIONAL DRAWINGS:

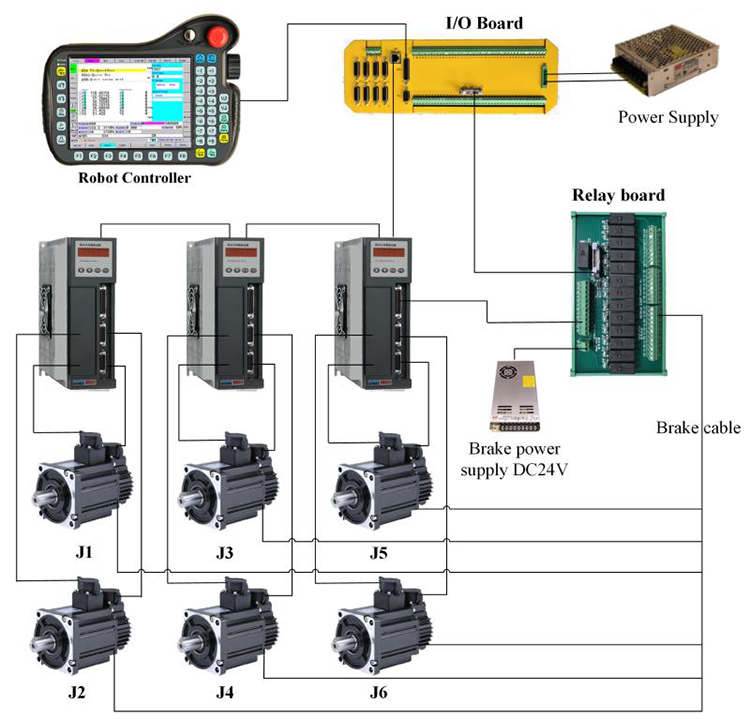

ROBOT CONTROLSYSTEM:

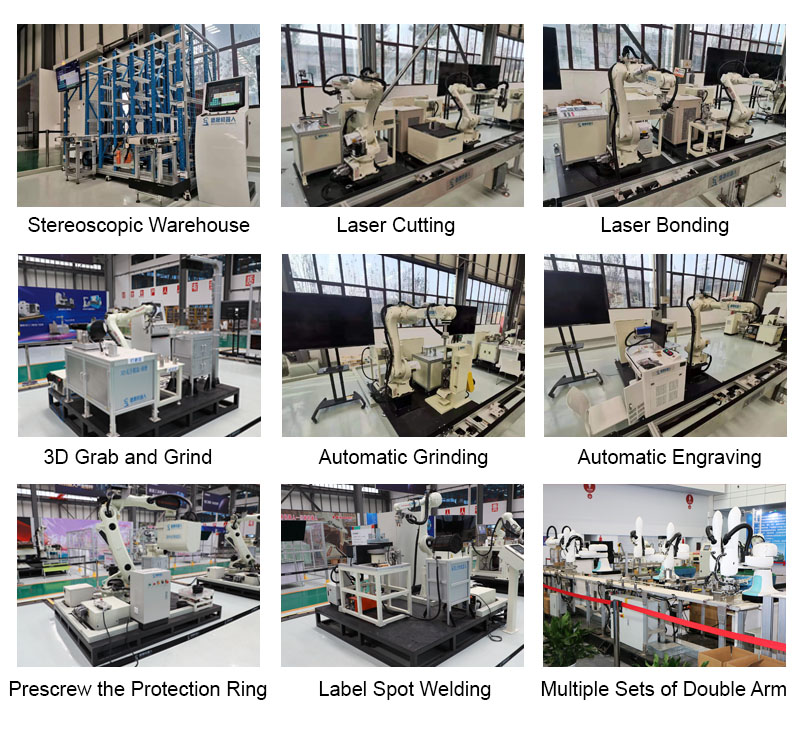

APPLICATIONS:

1,Material Handling: Industrial robot arms are ideal for efficiently and safely moving materials around a production or warehouse facility. They can lift, move, and manipulate heavy materials with ease, reducing the potential for worker fatigue or injury.

2,Assembly and Packaging: Industrial robot arms, including precision cylindrical robotic systems, can be programmed to assemble components and package finished products quickly and with a high degree of accuracy. This is essential for organizations looking to increase efficiency and reduce production errors.

3,Welding and Cutting: Industrial robot arms equipped with welding or cutting tools can perform these tasks with precision, speed, and accuracy. This makes them ideal for industries such as automotive manufacturing, where consistent welds are essential to maintain vehicle safety and quality.

FEATURES:

1,Programmability: Industrial robot arms are programmable machines that can be customized to perform a wide range of tasks with precision and accuracy. They can be easily reprogrammed for new applications, making them highly adaptable to changing production needs.

2,Flexibility: Industrial robot arms are highly flexible machines that can operate in confined spaces, at unusual angles, and in hazardous environments. They can also handle a wide range of materials, making them suitable for a wide range of industries.

3,Safety: Industrial robot arms are designed with built-in safety features to prevent accidents and reduce the potential for worker injuries. They can work in close proximity to humans without causing harm, making them an essential part of modern manufacturing processes.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: