The Unimate - A Revolutionary Robot

Advantages of The Unimate - A Revolutionary Robot:

1,Increased Productivity: Industrial robots can work continuously without the need for breaks, resulting in improved efficiency and higher production rates. They can perform tasks with high precision and accuracy, leading to reduced error rates and improved product quality.

2,Enhanced Safety: Robots can handle hazardous and repetitive tasks, minimizing the risk of injuries to human workers. By automating dangerous operations, such as heavy lifting or working in hazardous environments, industrial robots contribute to a safer work environment.

3,Cost Savings: While the initial investment for industrial robots can be significant, they can lead to long-term cost savings. They can operate at a lower cost compared to human labor, reducing expenses associated with labor costs, such as salaries, benefits, and training. Additionally, robots can work around the clock, maximizing production output and increasing overall efficiency.

The Unimate - A Revolutionary Robot:

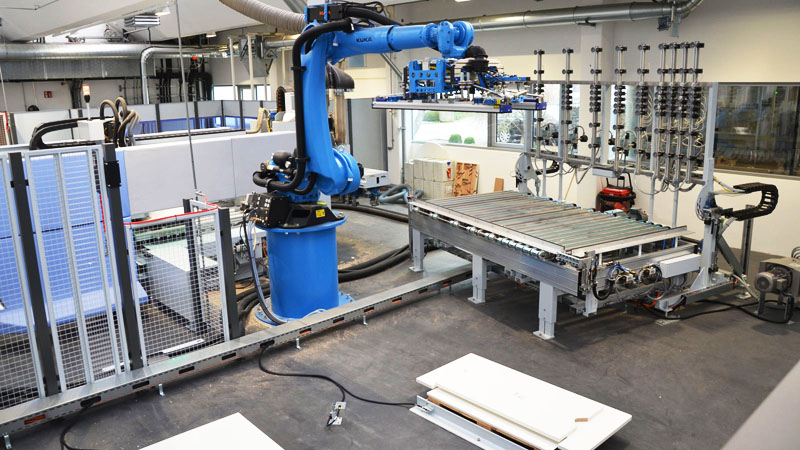

The Unimate, a revolutionary robot, has paved the way for automation robotics, transforming industries globally. With its innovative capabilities, it has revolutionized manufacturing processes, increasing productivity and efficiency. Alongside other robotics and automation companies, the Unimate has played a crucial role in driving advancements in the field. Nidec Automation, in particular, has emerged as a key player in Industry 4.0. With its cutting-edge technologies and solutions, Nidec Automation is enabling the integration of robotics, artificial intelligence, and the internet of things to create smart factories of the future.

PARAMETERS:

SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

Robot arm | Japanese Brand Robot | Fanuc | Kawasaki | |

German Brand Robot | KUKA | |||

Switzerland Brand | ||||

Main Performance | Speed Capacity | 8s per cycle | Adjust according to products and arrangement | |

Weight | About 8000kg | |||

Applicable Product | Cartons, cases,bags, | Containers,bottles,cans,buckets etc | ||

Power and Air | Compressed Air | 7bar | ||

Electric Power | 17-25 Kw | |||

Voltage | 380v | 3 Phases | ||

PLC | Siemens | |||

Frequency Converter | Danfoss | |||

Photoelectric Sensor | SICK | |||

Servo Motor | Panasonic | |||

Pneumatic Component | SMC | |||

Low-voltage Apparatus | Schneider | |||

Touch Screen | Schneider/Siemens | |||

Driving Motor | SEW | |||

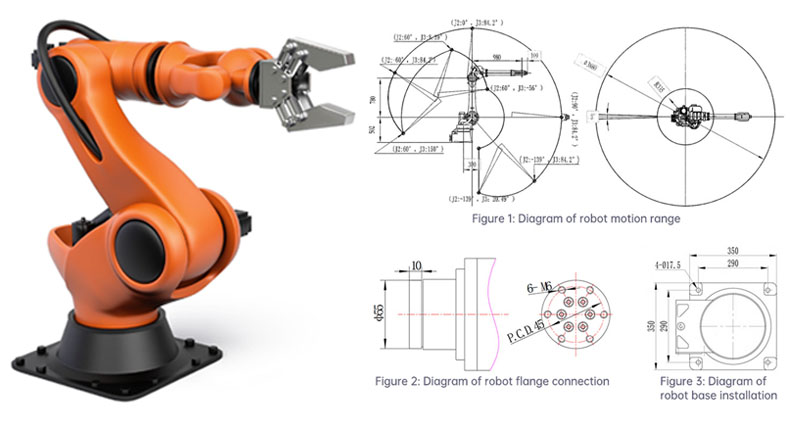

DIMENSIONAL DRAWINGS:

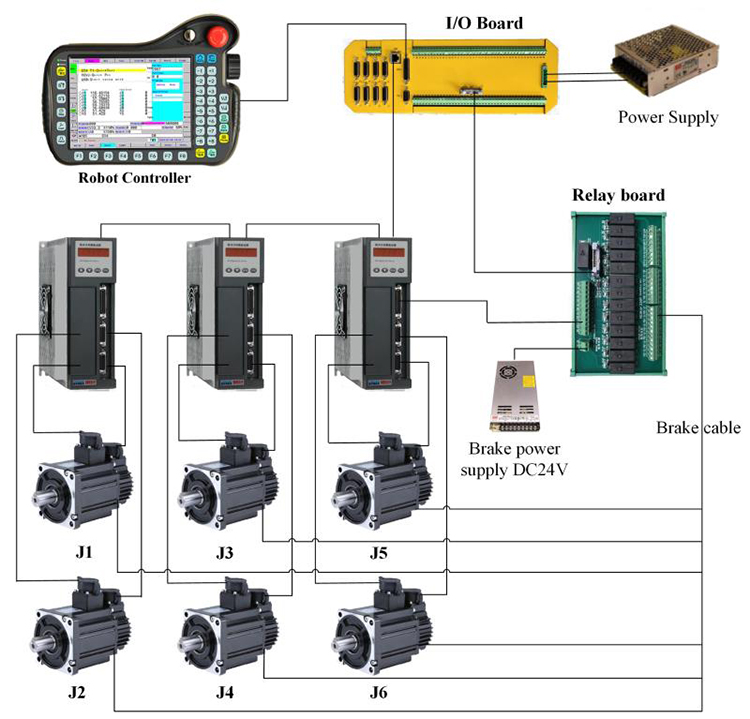

ROBOT CONTROLSYSTEM:

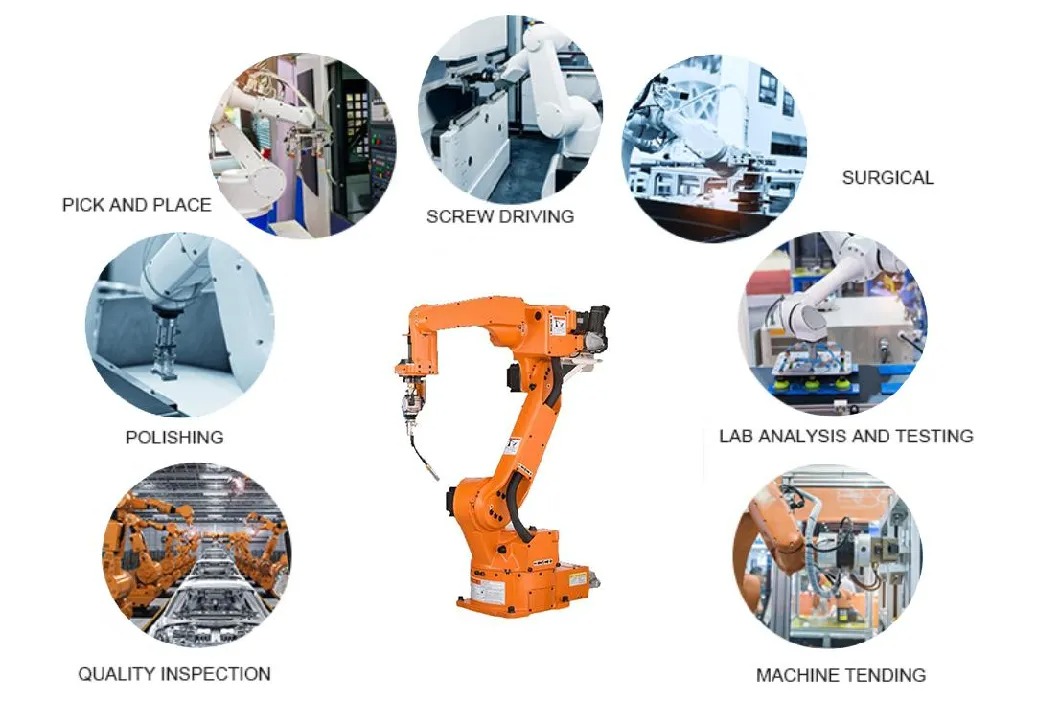

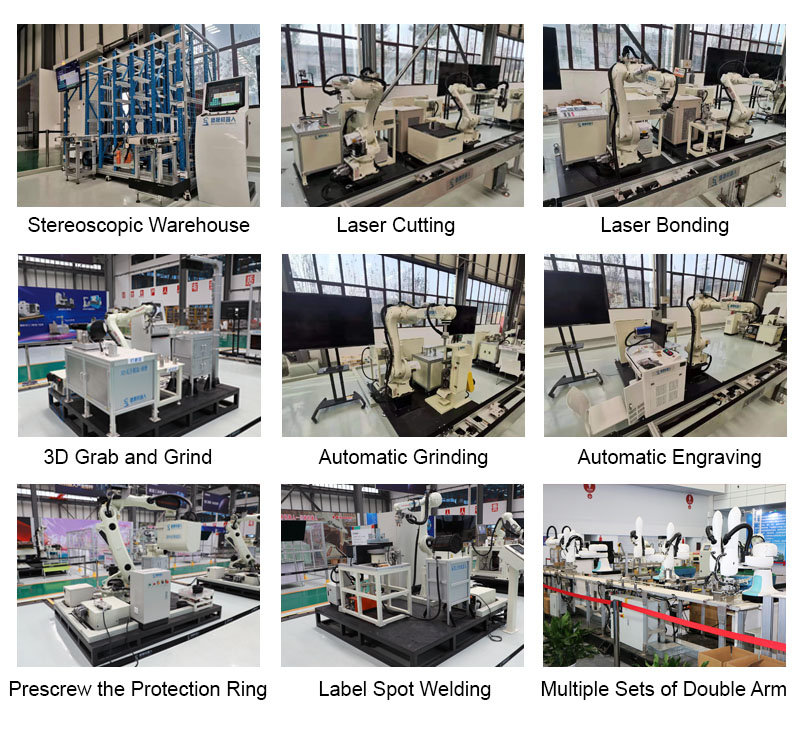

APPLICATIONS:

FEATURES:

1,Flexibility: Industrial robots are highly adaptable and can be programmed to perform various tasks efficiently. They can be easily reprogrammed or reconfigured to accommodate changing production needs, making them versatile assets in dynamic manufacturing environments.

2,Precision and Accuracy: With advanced sensors and control systems, industrial robots offer exceptional precision and accuracy in executing tasks. They can repeat movements with consistent precision, ensuring consistent quality and reducing errors in manufacturing processes.

3,Strength and Endurance: Industrial robots are designed to withstand demanding workloads. They have the strength to handle heavy loads, perform repetitive tasks with high endurance, and operate continuously without fatigue. This attribute enables them to maximize productivity and handle tasks that may be challenging or hazardous for human workers.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: