Mini Industrial Robot

Advantages of Mini Industrial Robot:

1,Compact Size: One of the advantages of a mini industrial robot is its compact size. These robots are smaller in comparison to traditional industrial robots, making them more versatile and suitable for use in tight spaces or confined environments. Their compact design allows them to be easily integrated into existing production lines or work cells without requiring significant modifications.

2,Flexibility: Mini industrial robots offer a high degree of flexibility in terms of their application possibilities. They can be used for a wide range of tasks such as assembly, pick and place, machine tending, and quality control. Their compact size and lightweight design enable them to maneuver and operate in various positions and orientations, enhancing their versatility in different manufacturing processes.

3,Cost-Effectiveness: Mini industrial robots often offer a more cost-effective solution compared to larger industrial robots. Their smaller size and simpler design generally translate into lower acquisition costs. Additionally, they often require less infrastructure and maintenance compared to larger robots, resulting in reduced operating expenses. This makes mini industrial robots an attractive option for small to medium-sized businesses or manufacturers with budget constraints.

Mini Industrial Robot:

Mini Industrial Robots have gained significant popularity in recent years, with numerous robotics and automation companies developing innovative solutions. One such example is the use of Cylindrical Coordinate Robots, which provide increased flexibility for tasks requiring a circular or cylindrical working area. Additionally, advancements in technology, such as 3D Printed 5 Axis Robot Arms, have made it possible to create compact and customizable robotic systems. These advancements in mini industrial robots highlight the continuous efforts of robotics and automation companies in improving efficiency and expanding the capabilities of industrial automation.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

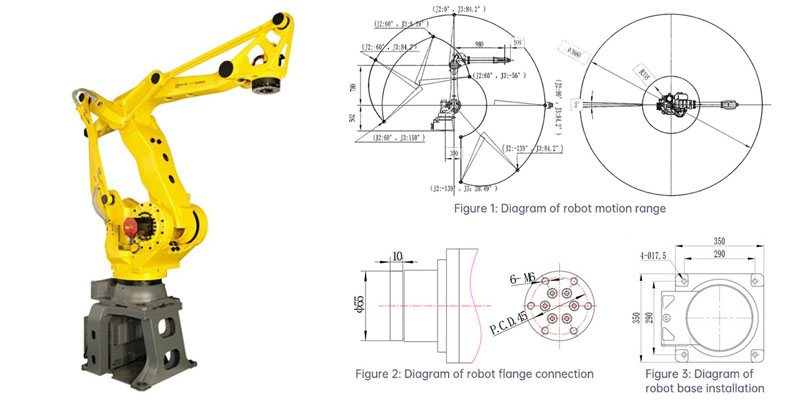

DIMENSIONAL DRAWINGS:

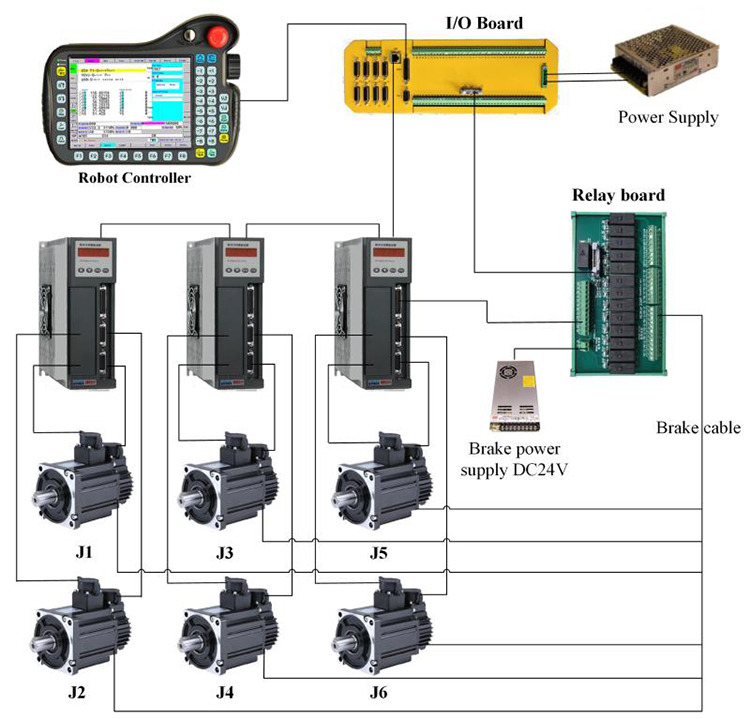

ROBOT CONTROLSYSTEM:

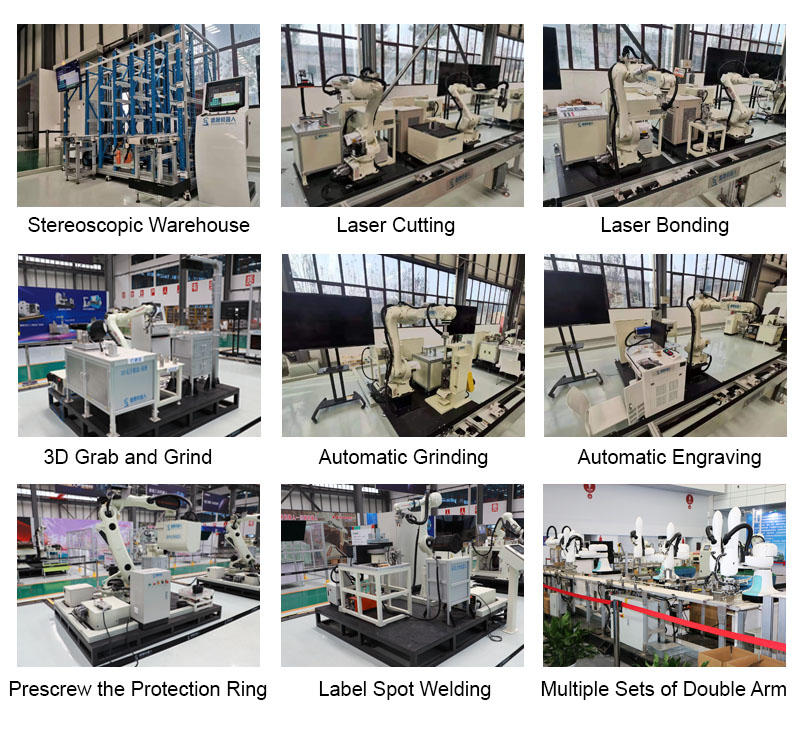

APPLICATIONS:

1,Electronics Assembly: Mini industrial robots are commonly used in electronics assembly applications. Their compact size and high precision make them ideal for handling small electronic components and precisely placing them onto circuit boards. These robots can perform tasks such as soldering, wire bonding, and surface mount technology, ensuring efficient and accurate assembly processes.

2,Packaging and Palletizing: Mini industrial robots are also widely applied in packaging and palletizing tasks. Their small size allows for easy integration into packaging lines, where they can efficiently pick up products, place them into containers, and arrange them onto pallets. These robots offer increased speed and accuracy in packaging operations, optimizing the overall production process.

3,Inspection and Quality Control: Mini industrial robots are valuable for inspection and quality control processes. Equipped with vision systems and sensors, they can analyze products for defects, measure dimensions, and conduct quality checks. These robots ensure consistent and reliable inspection results, leading to improved product quality and reduced waste in manufacturing.

FEATURES:

1,Small Size and Space Efficiency: The key characteristic of a mini industrial robot is its small size. These robots are designed to be compact, making them suitable for use in limited spaces or crowded environments. Their smaller footprint allows for easy integration into existing production lines or work cells, maximizing space efficiency in industrial settings.

2,High Flexibility and Versatility: Despite their small size, mini industrial robots offer a high degree of flexibility and versatility in application. They can be programmed to perform a wide range of tasks, such as assembly, pick and place, machine tending, and inspection. Their flexible design allows them to adapt to different industrial processes and handle various materials or components.

3,Ease of Use and Cost-Effectiveness: Mini industrial robots are known for their user-friendly interface and ease of use. They often come with intuitive programming software and can be quickly set up or reprogrammed for different applications. Additionally, due to their smaller size and simpler construction, these robots tend to be more cost-effective compared to larger industrial robots. They offer a cost-efficient automation solution for small to medium-sized businesses or manufacturers with limited budgets.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: