Pt Industrial Robotic Automation Solution

Advantages of Pt Industrial Robotic Automation Solution:

1,Increased Productivity: Industrial robotic automation improves productivity by streamlining processes and eliminating manual labor. Robots can work at a faster pace with high precision, reducing cycle times and improving overall efficiency. This leads to increased production outputs and higher throughput.

2,Improved Quality: Robotic automation ensures consistent and accurate performance, leading to improved product quality. Robots can perform tasks with precision, reducing the chances of human error and variability. This results in products that meet or exceed quality standards, minimizing defects and rework.

3,Enhanced Worker Safety: By automating repetitive and hazardous tasks, industrial robotic automation improves worker safety. Robots are designed to handle dangerous and physically demanding tasks, reducing the risk of injuries and accidents. This creates a safer working environment and allows human workers to focus on more complex and value-added activities.

Please Contact Us For Detailed Technical Parameters.

Pt Industrial Robotic Automation Solution:

Pt Industrial Robotic Automation Solution in our company can save 92% on the cost of a manned patrol.Please Contact Us For Detailed Technical Parameters.

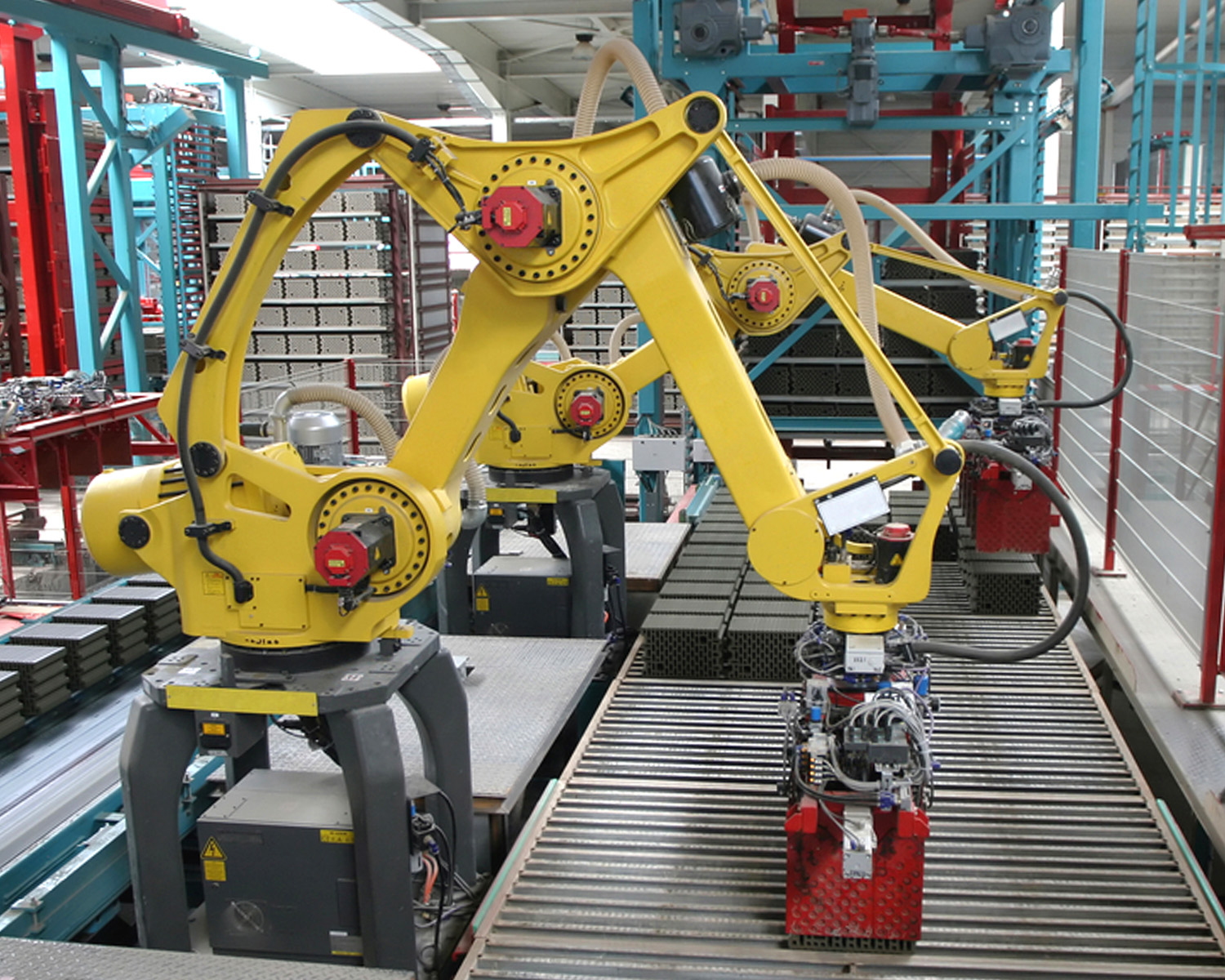

Pt Industrial Robotic Automation, also known as process technology industrial Robotic Automation, plays a significant role in various industries, including logistics. The integration of robotics in logistics brings numerous benefits, with active control automation being a key component of this transformation. Companies like ABB have been instrumental in driving this change.

Pt Industrial Robotic Automation in logistics improves efficiency by automating repetitive tasks such as sorting, packing, and palletizing. This reduces manual labor and accelerates the movement of goods through the supply chain. The active control automation allows for precise and synchronized movements, ensuring optimal performance and minimizing errors.

Companies like ABB Robotics & Discrete Automation have been at the forefront of developing advanced robotic solutions for logistics. Their robots are equipped with sophisticated technologies such as vision systems, allowing for accurate identification and handling of products. These robots not only streamline operations but also contribute to improved customer service and satisfaction.

In conclusion, the integration of Pt Industrial Robotic Automation, robotics in logistics, active control automation, and the expertise of companies like ABB Robotics & Discrete Automation revolutionize the logistics industry. This combination brings increased efficiency, accuracy, and customer satisfaction, ultimately driving overall business success.

PARAMETERS:

SPECIFICATIONS FOR ROBOT PALLETIZER | ||||

Robot arm | Japanese Brand Robot | Fanuc | Kawasaki | |

German Brand Robot | KUKA | |||

Switzerland Brand | ABB | |||

Main Performance | Speed Capacity | 8s per cycle | Adjust according to products and arrangement | |

Weight | About 8000kg | |||

Applicable Product | Cartons, cases,bags, | Containers,bottles,cans,buckets etc | ||

Power and Air | Compressed Air | 7bar | ||

Electric Power | 17-25 Kw | |||

Voltage | 380v | 3 Phases | ||

PLC | Siemens | |||

Frequency Converter | Danfoss | |||

Photoelectric Sensor | SICK | |||

Servo Motor | Panasonic | |||

Pneumatic Component | SMC | |||

Low-voltage Apparatus | Schneider | |||

Touch Screen | Schneider/Siemens | |||

Driving Motor | SEW | |||

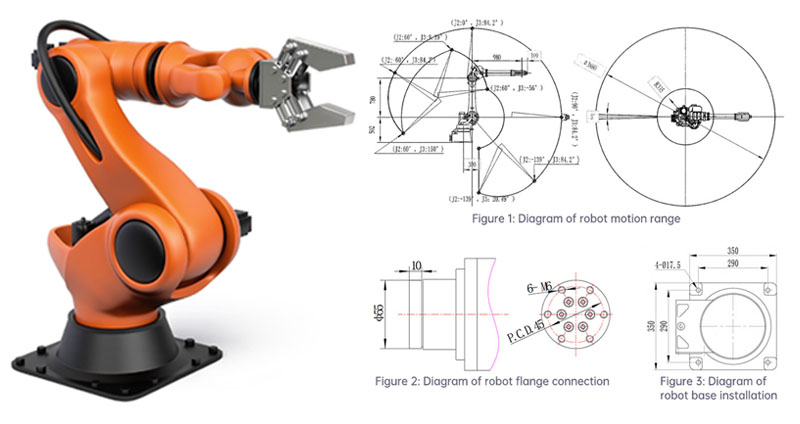

DIMENSIONAL DRAWINGS:

ROBOT CONTROLSYSTEM:

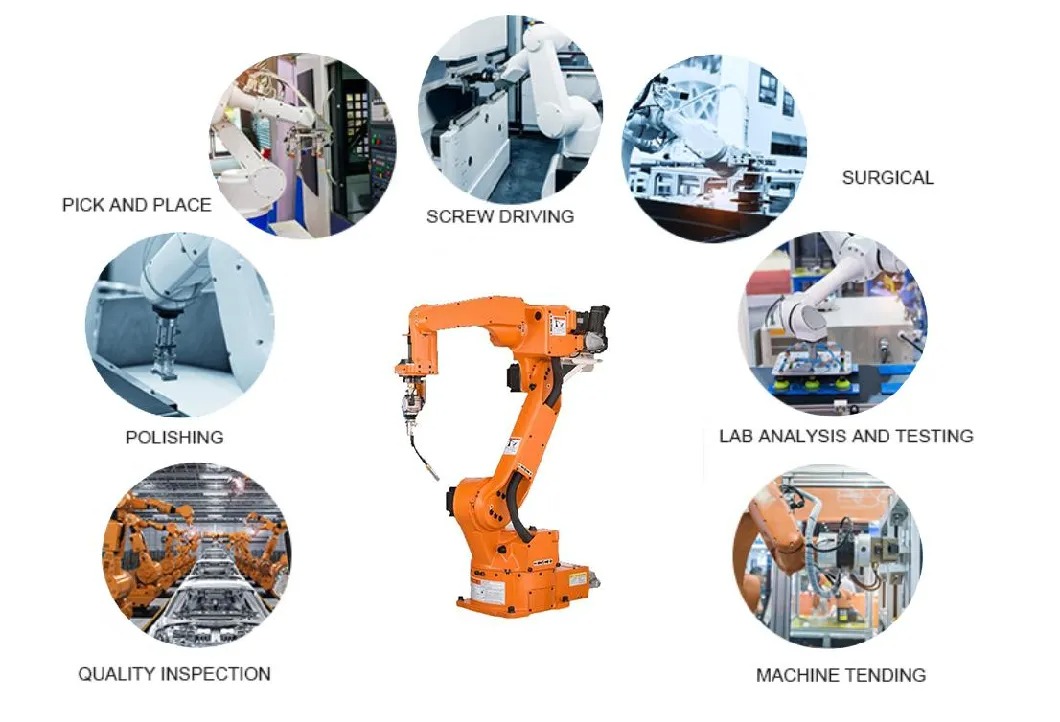

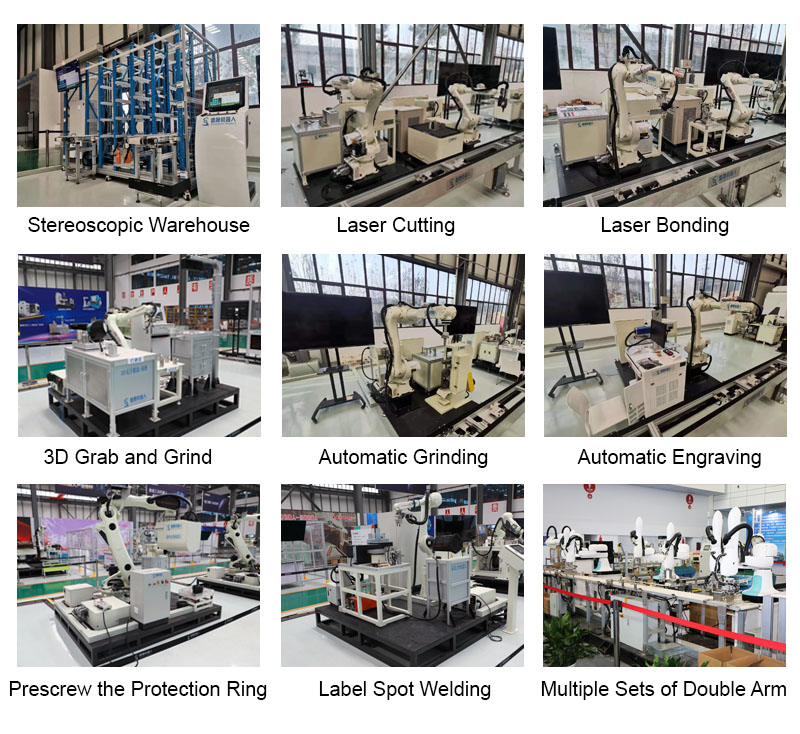

APPLICATIONS:

FEATURES:

1,Customization and Flexibility: Pt Industrial Robotic Automation offers the ability to customize robotic systems according to specific industry requirements. This customization allows for the flexibility to adapt to various manufacturing processes and handle diverse tasks. The ability to program robots to perform different functions and tasks enhances overall operational efficiency.

2,Integration with Existing Systems: Pt Industrial Robotic Automation is designed to seamlessly integrate with existing manufacturing systems. This allows for a smooth transition from traditional manufacturing to automated processes. This integration ensures that the robotic automation systems work in coordination with other equipment, maximizing productivity and reducing downtime.

3,Advanced Control and Monitoring Capabilities: Pt Industrial Robotic Automation includes advanced control and monitoring systems. These systems enable real-time tracking and analysis of the production process, allowing for immediate adjustments and optimizations. The ability to monitor performance metrics, detect issues, and make proactive improvements enhances overall productivity and quality.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

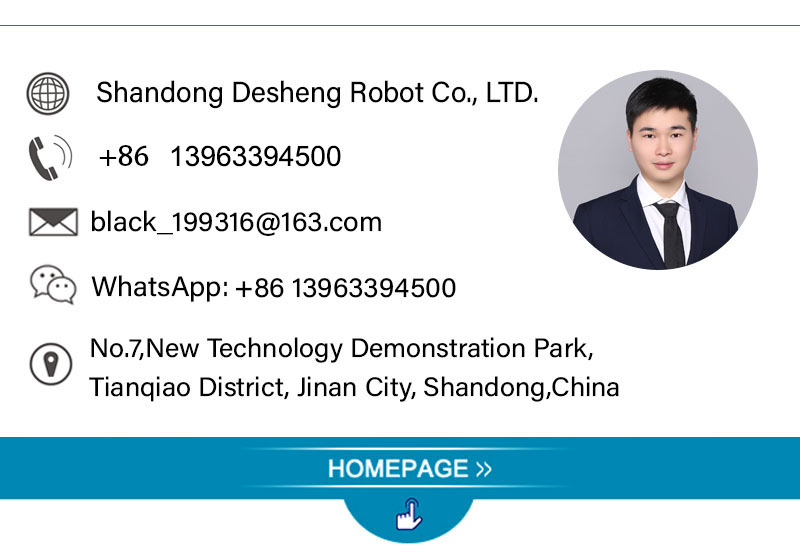

CONTACT US: