New Robotics Technology 2021

Advantages of New Robotics Technology 2021:

1,Increased Productivity: Industrial robots significantly improve productivity by automating repetitive tasks and performing them at a faster rate than human workers. With their high-speed movements and precise operations, they can complete manufacturing processes quickly and consistently, leading to enhanced production output and efficiency.

2,Improved Quality and Accuracy: Industrial robots offer superior accuracy and precision in tasks like assembly, welding, and machining. With their repeatable movements and advanced sensors, they can consistently deliver high-quality products, reduce errors, and improve overall product consistency. This results in fewer defects and rework, leading to higher customer satisfaction.

3,Enhanced Worker Safety: Industrial robots are designed to work in hazardous or physically demanding environments, reducing the exposure of human workers to potentially dangerous conditions. By automating tasks that pose risks to human operators, such as heavy lifting or working with hazardous materials, robots help protect workers' safety and health, creating safer work environments.

New Robotics Technology 2021:

New Robotics Technology 2021: articulated robot arm, Cartesian Robot Arm, Unimate First Robot

In the ever-evolving field of robotics, exciting advancements continue to emerge in 2021. Three notable developments are the Articulated Robot arm, Cartesian Robot Arm, and the Unimate – the first robot.

The articulated robot arm is a cutting-edge technology that replicates the movements of a human arm. With multiple joints and segments, it offers enhanced flexibility and dexterity in performing various tasks. This advancement has revolutionized industries such as manufacturing, healthcare, and even space exploration.

Another significant innovation is the Cartesian robot arm. This type of robot arm operates along a three-dimensional coordinate system, providing precise and accurate movements. Its versatility makes it suitable for applications ranging from assembly lines and pick-and-place operations to 3D printing and CNC machining.

Lastly, we have the Unimate – the first-ever industrial robot. Developed by George Devol and Joseph Engelberger in the 1960s, the Unimate revolutionized the manufacturing industry. It could perform tasks previously done by humans, such as welding and material handling. This breakthrough laid the foundation for the modern robotic industry we know today.

In conclusion, the field of robotics has witnessed remarkable advancements in 2021. The articulated robot arm, Cartesian robot arm, and Unimate – the first robot – have all contributed to pushing the boundaries of automation. As technology continues to evolve, we can only anticipate even more exciting developments in the future.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

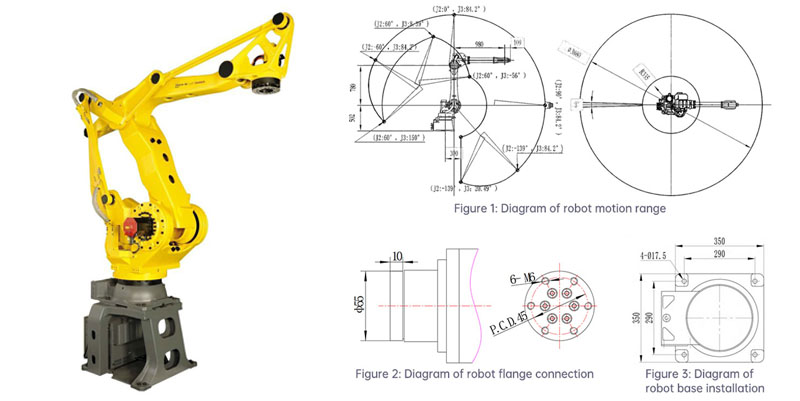

DIMENSIONAL DRAWINGS:

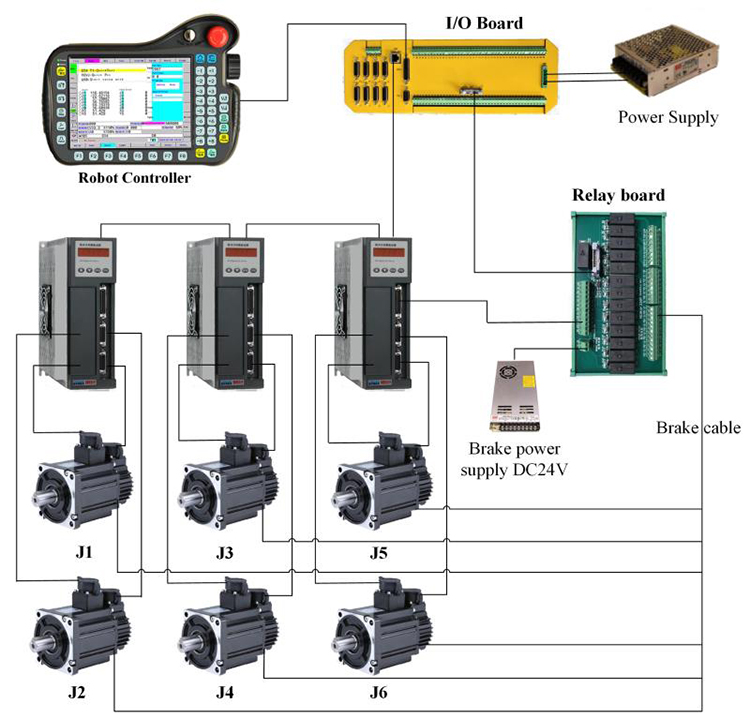

ROBOT CONTROLSYSTEM:

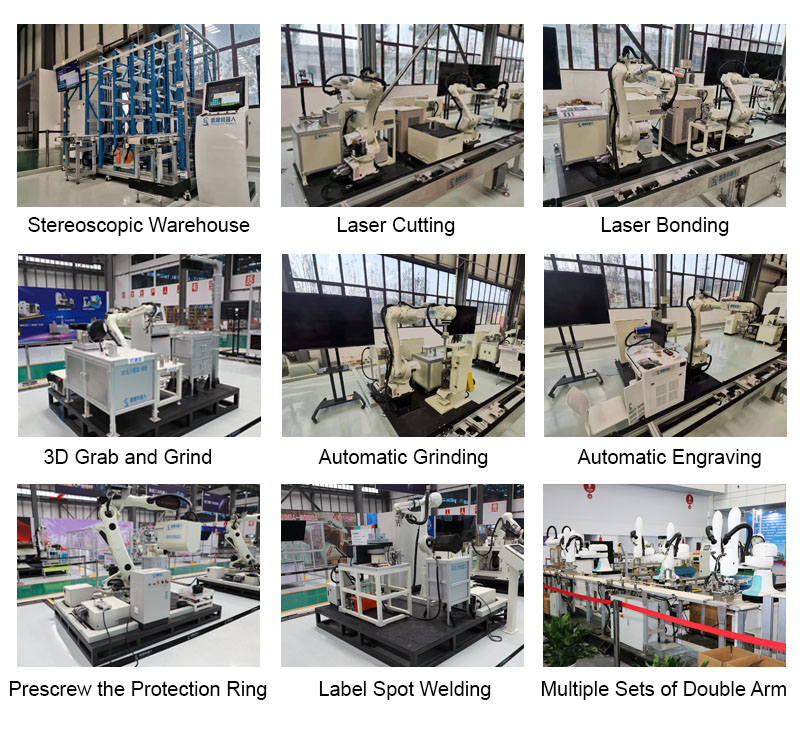

APPLICATIONS:

1,Manufacturing Industry: New robotics technology has transformed the manufacturing industry by automating various stages of the production process. Robots equipped with advanced sensors and algorithms can perform tasks such as assembly, packaging, and quality control with high precision and efficiency. This not only reduces costs and improves productivity but also enhances the safety of workers by automating hazardous or repetitive tasks.

2,Healthcare Sector: Robotics technology has found diverse applications in the healthcare sector. Surgical robots, for instance, have revolutionized minimally invasive surgeries by offering greater precision and control to surgeons. Rehabilitation robots aid in physical therapy and assist patients in regaining mobility. Additionally, robots are used for medication dispensing, patient monitoring, and even in telemedicine, enabling remote diagnosis and treatment.

3,Agriculture and Farming: With the growing demand for sustainable and efficient farming practices, robotics technology is making significant inroads in the agricultural sector. Robots equipped with cameras, AI algorithms, and robotic arms can autonomously perform tasks such as seeding, planting, and harvesting crops. Autonomous drones and precision agriculture robots assist in crop monitoring, pest control, and irrigation management. This technology not only improves productivity but also reduces resource wastage and environmental impact.

FEATURES:

1,Versatility: New robotics technology boasts a high degree of versatility, allowing it to be applied across various industries and tasks. These robots are designed to handle a wide range of operations, from complex assembly and precise movements to heavy lifting and detailed tasks. Their adaptability makes them suitable for diverse applications, enabling automation in areas that were previously considered challenging or impossible.

2,Advanced Sensors and Perception: Robotics technology incorporates advanced sensors and perception systems that enable the robots to interact with their environment effectively. Technologies such as computer vision, LiDAR, and force sensors allow robots to perceive and interpret their surroundings accurately. This enables them to navigate obstacles, handle delicate objects, and collaborate safely with humans. These advanced sensing capabilities contribute to increased safety, precision, and efficiency.

3,Integration of Artificial Intelligence (AI): New robotics technology integrates AI algorithms and machine learning, enabling robots to learn from experience, adapt to changing conditions, and make intelligent decisions. AI-powered robots can analyze large volumes of data, recognize patterns, and optimize their performance accordingly. This not only improves productivity but also facilitates human-robot collaboration, as robots can understand and respond to human commands or gestures. This integration of AI in robotics technology empowers robots with autonomous decision-making abilities, enhancing their overall efficiency and effectiveness.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: