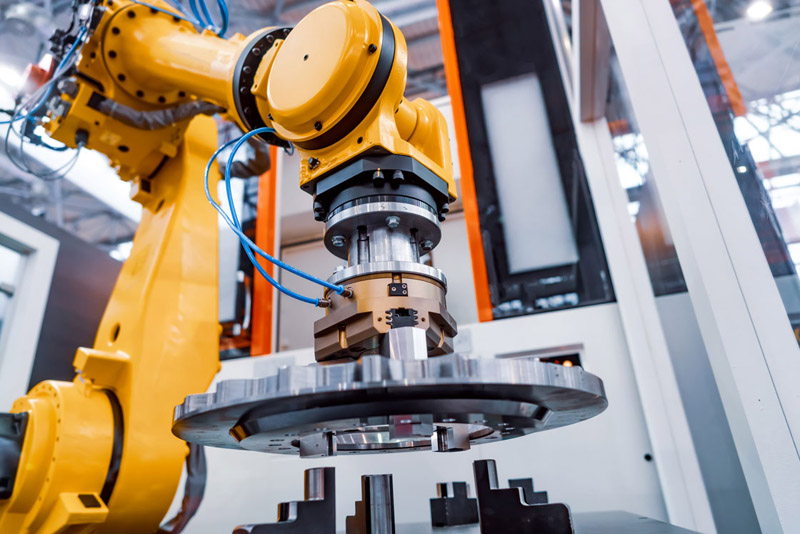

6 Axis Articulated Robot

Advantages of 6 Axis Articulated Robot:

1,Flexible and Agile Movement: The 6 Axis Articulated Robot offers excellent flexibility and agility in its movements. With its six degrees of freedom, it can maneuver and reach objects in complex and confined spaces. This flexibility enables it to perform a wide range of tasks with ease and precision.

2,Enhanced Productivity and Efficiency: The 6 Axis Articulated Robot significantly improves productivity and efficiency in industrial operations. Its ability to handle multiple tools and perform various tasks reduces the need for multiple machines or manual labor. This leads to streamlined processes, reduced cycle times, and increased throughput.

3,Versatile Applications: The 6 Axis Articulated Robot finds applications in various industries such as manufacturing, automotive, and electronics. It can perform tasks such as welding, assembly, material handling, and inspection with high accuracy and repeatability. Its versatility allows for quick adaptation to different production requirements, making it a valuable asset for diverse operations.

6 Axis Articulated Robot:

The industrial robotics landscape is evolving rapidly with technologies like the 6 Axis Articulated Robot, Mir Mobile Industrial Robots, Ur20 Universal Robots, and Robotics as a Service companies.

The 6 Axis Articulated Robot offers exceptional flexibility and agility in its movements, making it suitable for a wide range of applications. Its versatile six degrees of freedom enable precise and intricate tasks, enhancing productivity and efficiency in manufacturing processes.

Mir Mobile Industrial Robots specialize in autonomous mobile robots, optimizing logistics and warehousing operations. These robots intelligently navigate complex environments, streamlining material transportation and improving operational efficiency.

Ur20 Universal Robots provide collaborative robotic solutions that are safe and easy to program. With their lightweight design and human-robot collaboration features, they offer flexible automation options for various manufacturing tasks, enhancing productivity and worker safety.

In response to increasing demand, Robotics as a Service companies have emerged. These companies offer robot rental, maintenance, and support services, making automation accessible and cost-effective for businesses without large upfront investments.

The combination of the 6 Axis Articulated Robot, Mir Mobile Industrial Robots, Ur20 Universal Robots, and Robotics as a Service companies is revolutionizing industrial automation. It leads to enhanced productivity, improved operational efficiency, and greater flexibility in adapting to changing manufacturing needs.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

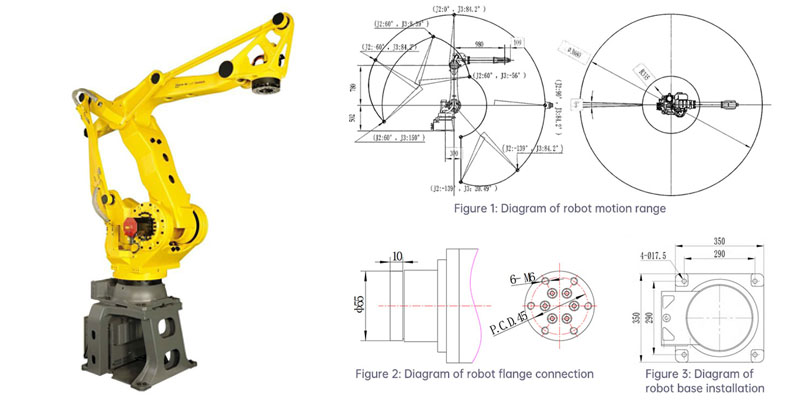

DIMENSIONAL DRAWINGS:

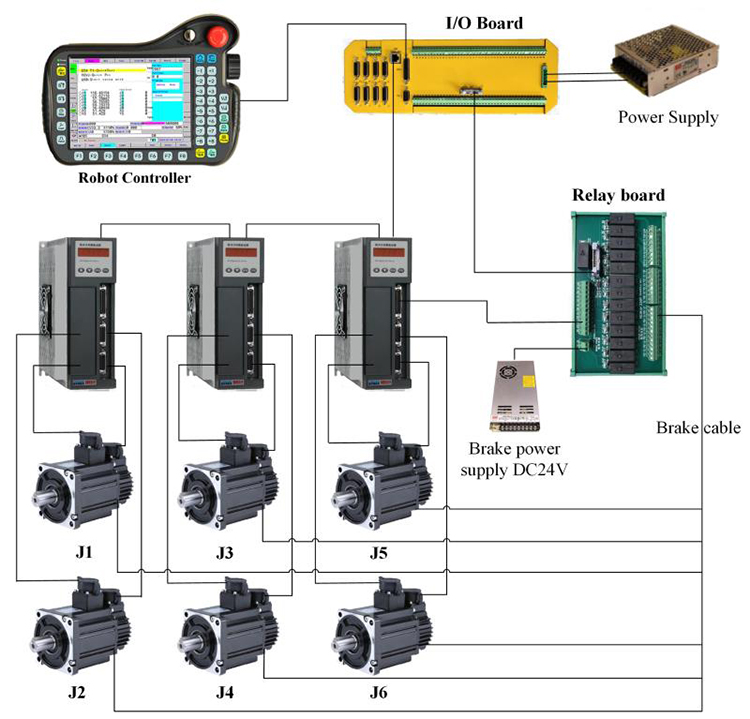

ROBOT CONTROLSYSTEM:

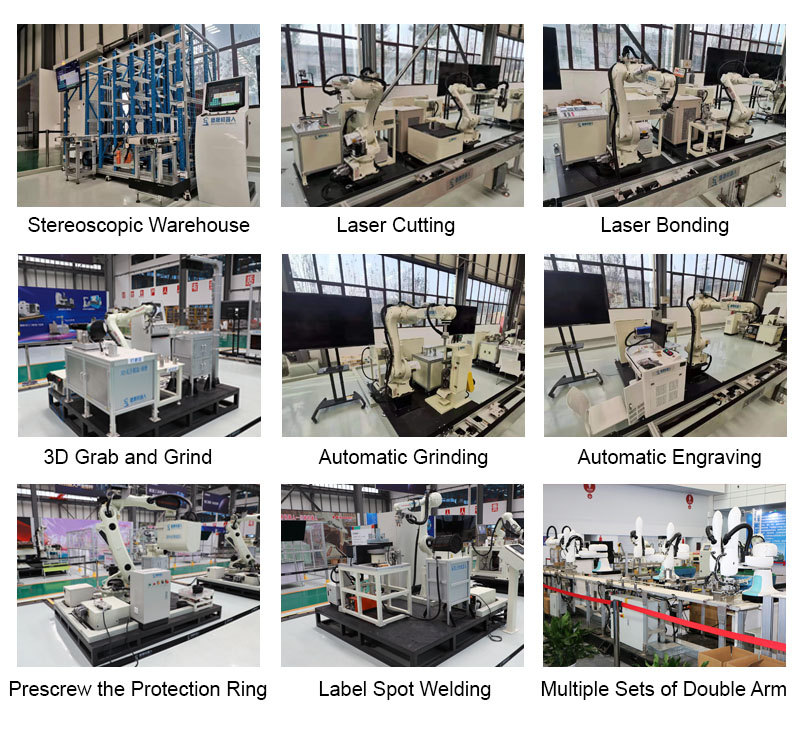

APPLICATIONS:

1,Welding and Cutting: The 6 Axis Articulated Robot is extensively used in welding and cutting applications. Its flexible arm, combined with advanced sensors and precision control, allows for precise and consistent welding operations. It can handle complex weld geometries and work with a variety of materials, making it suitable for industries such as automotive, aerospace, and metal fabrication.

2,Material Handling and Assembly: The 6 Axis Articulated Robot is well-suited for material handling and assembly tasks. It can efficiently lift, move, and position objects with precision, enhancing productivity on assembly lines. Its ability to handle various shapes and sizes, coupled with its speed and agility, makes it ideal for industries such as electronics, consumer goods, and logistics.

3,Inspection and Quality Control: Leveraging its accuracy and range of motion, the 6 Axis Articulated Robot is employed in inspection and quality control applications. It can perform precise measurements, check for defects, and ensure compliance with standards. This is valuable in industries where precision and quality assurance are critical, including automotive, electronics, and pharmaceuticals.

FEATURES:

1,Flexibility: The 6 axis articulated robot is designed with six degrees of freedom, allowing it to move and position itself in various orientations and reach a wide range of work areas. This flexibility enables it to perform complex tasks such as assembly, welding, and material handling efficiently.

2,High precision: The robot is equipped with precision motors and sensors that allow for accurate and repeatable movements. This level of precision is essential when dealing with delicate components or performing tasks that require tight tolerances.

3,Improved productivity: The 6 axis articulated robot can perform multiple tasks simultaneously, reducing the need for multiple robots or manual labor. This not only increases productivity but also improves overall efficiency in the production process. Additionally, the robot can work at a consistent pace without fatigue, leading to higher output and reduced cycle times.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: