Types Of Manufacturing Robots

Advantages of Types Of Manufacturing Robots:

1,Improve production efficiency: Build robots, such as "Everlast Welders Tig," that can perform repetitive tasks with great speed and accuracy when needed. This can not only greatly improve production efficiency, but also reduce the manufacturing cycle of products and speed up the workflow on the production line.

2,Improve product quality: Robots, such as those used for welding with "Stainless Steel Welding Wire," can replace human operators at every stage of the manufacturing process, reducing possible human errors and thus improving product quality and consistency. At the same time, the robot can also operate at a higher level of precision, making more complex and sophisticated parts and assemblies.

3,Improve work safety: Build robots that can perform dangerous or significant health risk tasks, such as high temperature, high pressure or the handling of toxic and dangerous chemicals. For example, using the "Best Tig Welder For Beginners" robot can provide a safer working environment for employees. Robots can reduce the risk of workers working in hazardous environments, thereby reducing workplace accidents and injuries.

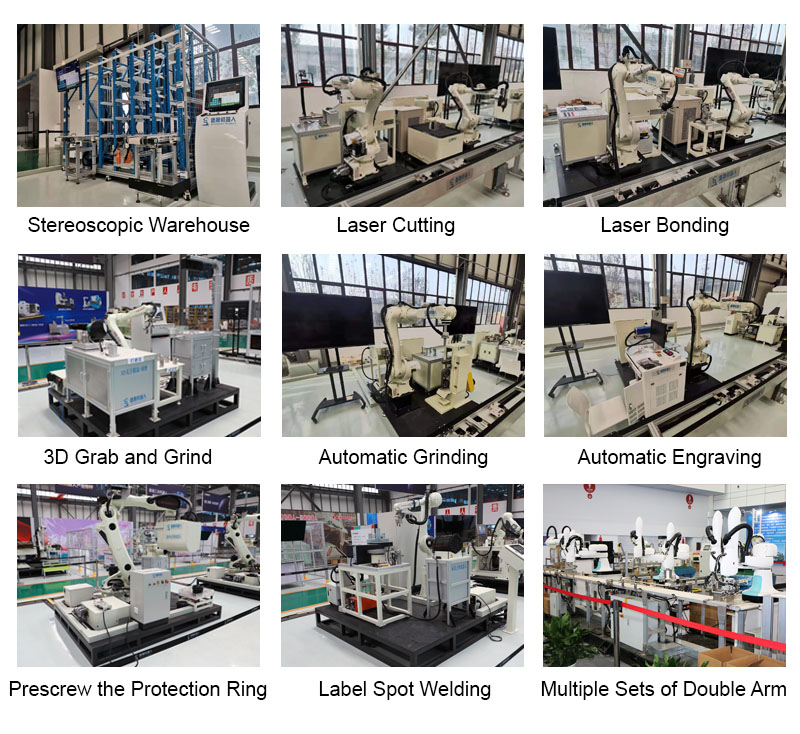

Types Of Manufacturing Robots:

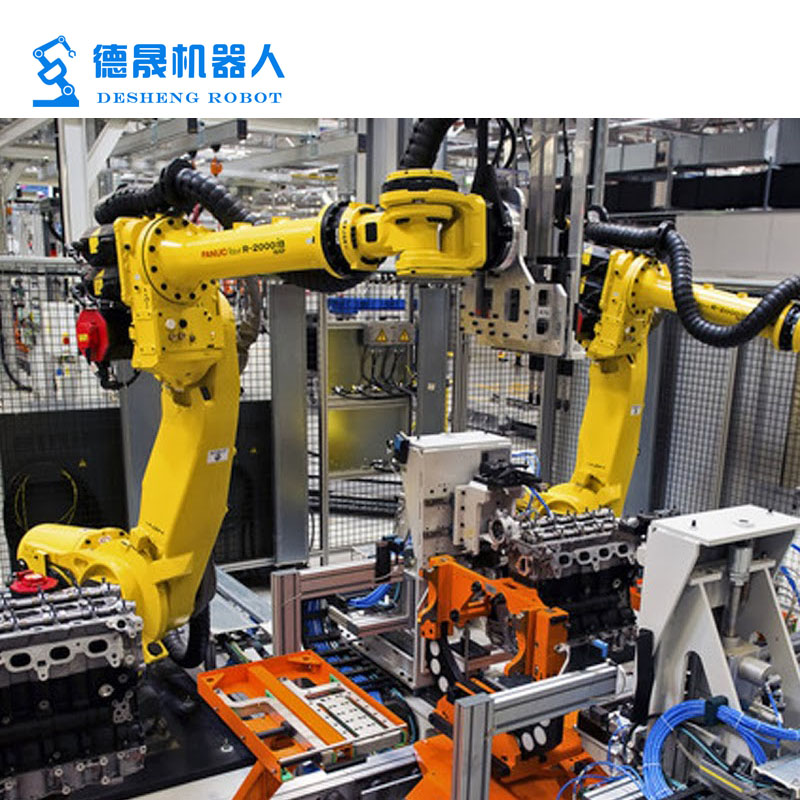

Nowadays, manufacturing robots have become a popular choice for many manufacturing companies to improve production efficiency. Common types of manufacturing robots include Everlast Welders Tig robots and Stainless Steel Welding Wire robots. These robots can perform repetitive tasks during the manufacturing process to improve productivity and greatly reduce human errors, thus improving product quality. Furthermore, robots can operate at a higher level of precision, making more complex and sophisticated parts and assemblies. Most importantly, robots can replace human workers to perform dangerous or high-risk tasks, such as handling toxic chemicals, providing a safer working environment for employees. If you're looking for the best Tig Welder For Beginners, you can choose to use the best Tig Welder For Beginners robot, which can improve productivity and work safety at the same time. Therefore, by using these types of manufacturing robots, manufacturing companies can improve productivity, improve product quality, and provide a safer working environment.

PARAMETERS:

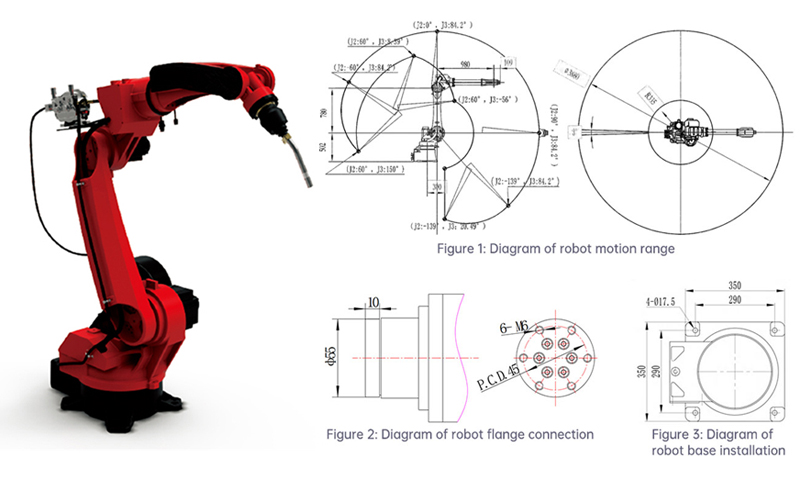

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

DIMENSIONAL DRAWINGS:

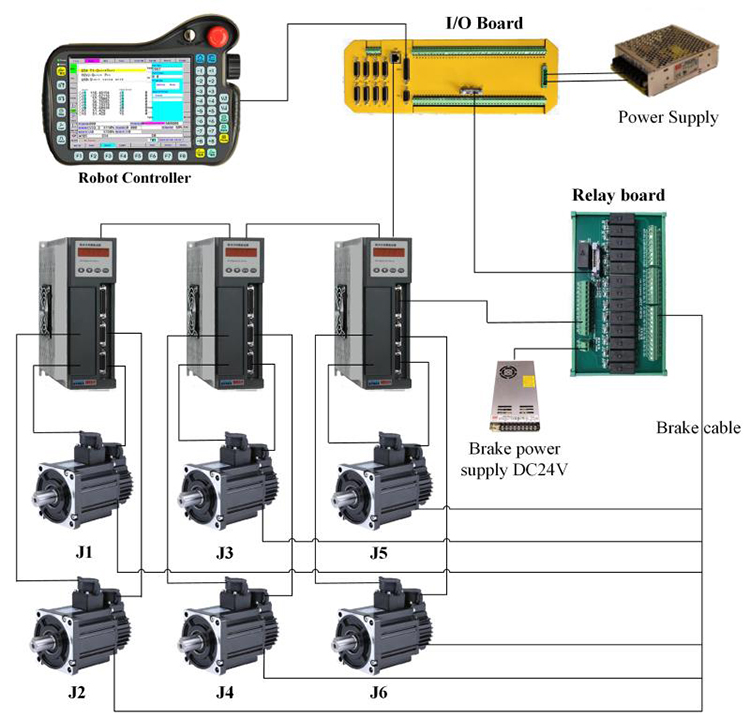

ROBOT CONTROLSYSTEM:

ADVANTAGE:

1,Loose Saving

May be operated 24 hours, effec-tively keep hard art work prices. in additionthe use of organization manipulator operation mode, computerized meeting line to store the internet page, sothat the entire plant planning greater compact.

2,Immoderate Production Wellknown Standard Overall Performance

Manipulator manufacturing of a producttime is everyday in the identical manufacturing cycle, the output is regular product yield is excessive, immoderate manufacturing benefits.

3,Excessive Stability

Production operation, excessive precision,immoderate stability,can assure man or woman-nel,in preference to manual risky operations.

FEATRUES:

1,Assist as hundreds as 12 axis manage, realizes the manipulate of outdoor axes (traveling axes and positioner).

2,Structural optimization set of guidelines suitable for the frame control of numerous styles of shape.

3,Open shape for synchronization of worldwide era and extension of skills.

4,Software program software software application talents facilitate not unusual enjoy control. technique capabilities make programming easy.

5,Modular putting of capabilities appropriate for severa applications. safety module ensures comfortable production of the robots.

6,Suitable for more than one increments; absolute servo. advanced computer bus connection guarantees reliability and practicability.

APPLICATIONS:

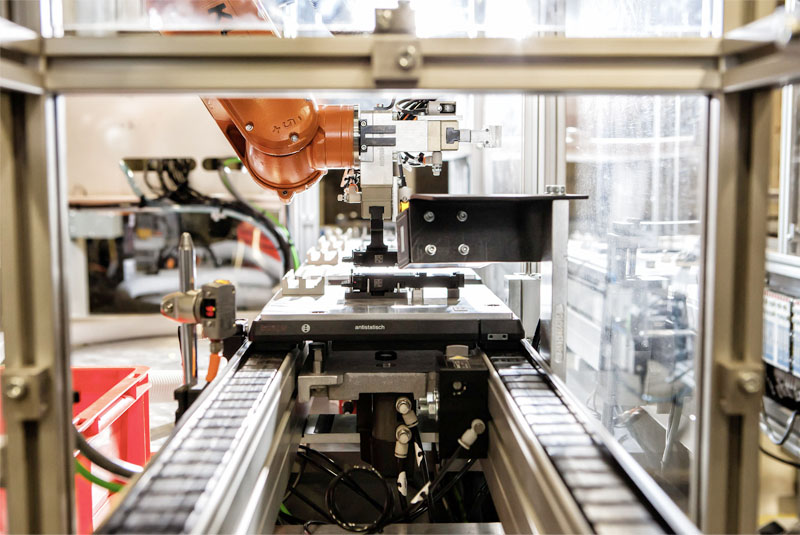

1, Production line, and automobile factors manufacturing. the pocket e-book region requires coordination a number of the positioner and welding robotic to advantage computerized welding, with seamless movement that meets the welding track, speed, and gun feature necessities.

2, The welding robot production reduces manpower fees and improves normal performance through connecting workpiece conveying traces to form a manufacturing line.

3, Car factors manufacturing drastically benefits from welding robots, mainly within the car chassis welding device, wherein welding robot modified in advance operations, enhancing each welding splendid and operation time.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: