The First Industrial Robot

Advantages of The First Industrial Robot:

1,Efficiency and Productivity: The first industrial robot revolutionized manufacturing processes by significantly increasing efficiency and productivity. It replaced manual labor in repetitive and labor-intensive tasks, enabling faster production cycles and higher output levels. With their consistent performance and ability to work non-stop, industrial robots revolutionized the manufacturing industry.

2,Precision and Quality: The first industrial robot brought unmatched precision and accuracy to manufacturing operations. It allowed for precise movements, optimal control, and consistent results in tasks such as welding, assembly, and material manipulation. This level of precision improved overall product quality, reduced defects, and increased customer satisfaction.

3,Safety and Risk Reduction: The first industrial robot introduced a new level of safety to manufacturing environments. By taking on dangerous tasks, it minimized the risk of accidents and injuries to human workers. They were designed with advanced sensors and safety protocols to ensure safe operation, further enhancing workplace safety.

The First Industrial Robot:

The first industrial robot revolutionized manufacturing with its introduction of automation. Today, this technology extends beyond manufacturing and has found applications in various sectors. One such example is packaging process automation, where industrial robots streamline packaging operations, ensuring efficiency and accuracy. Industrial control engineering plays a vital role in optimizing the performance of these robots by integrating advanced control systems. Additionally, dairy automation solutions employ robotic technology to enhance dairy production processes, ensuring quality, productivity, and cost-effectiveness. The convergence of the first industrial robot, packaging process automation, industrial control engineering, and dairy automation solutions has transformed industries by enabling streamlined operations and improved output.

PARAMETERS:

SPECIFICATIONS FOR robot PALLETIZER | ||||

Robot arm | Japanese Brand Robot | Fanuc | Kawasaki | |

German Brand Robot | KUKA | |||

Switzerland Brand | ||||

Main Performance | Speed Capacity | 8s per cycle | Adjust according to products and arrangement | |

Weight | About 8000kg | |||

Applicable Product | Cartons, cases,bags, | Containers,bottles,cans,buckets etc | ||

Power and Air | Compressed Air | 7bar | ||

Electric Power | 17-25 Kw | |||

Voltage | 380v | 3 Phases | ||

PLC | Siemens | |||

Frequency Converter | Danfoss | |||

Photoelectric Sensor | SICK | |||

Servo Motor | Panasonic | |||

Pneumatic Component | SMC | |||

Low-voltage Apparatus | Schneider | |||

Touch Screen | Schneider/Siemens | |||

Driving Motor | SEW | |||

DIMENSIONAL DRAWINGS:

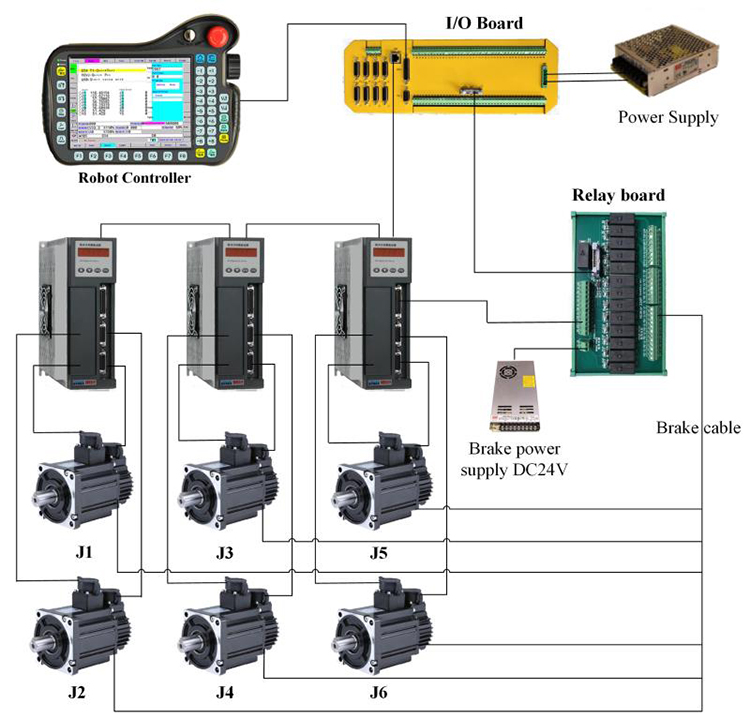

ROBOT CONTROLSYSTEM:

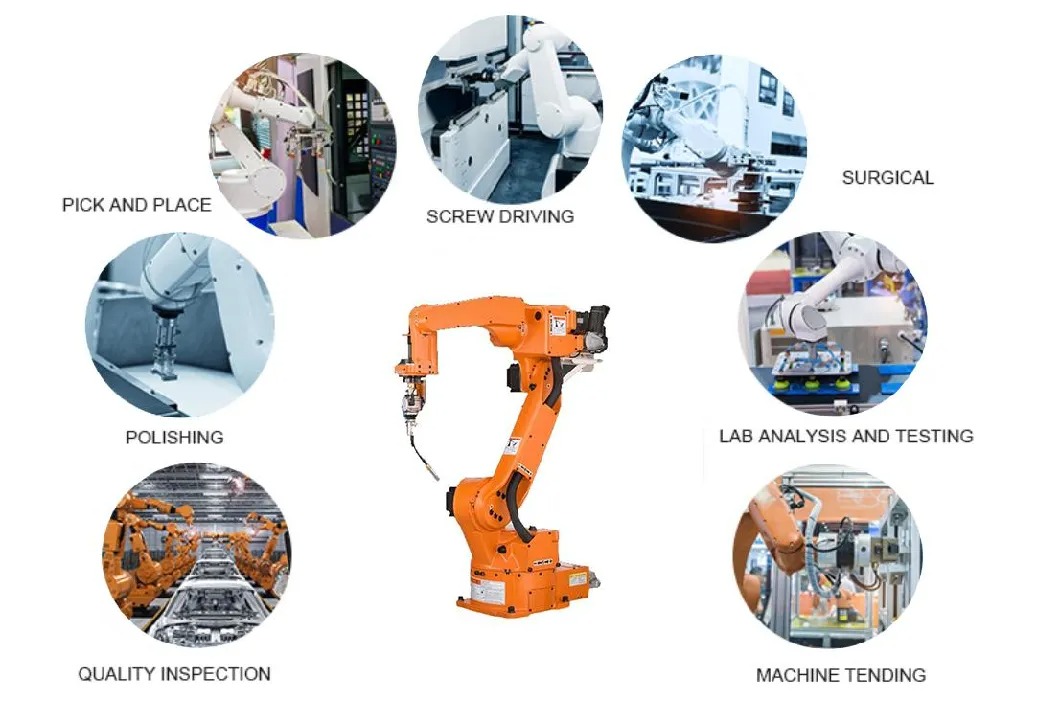

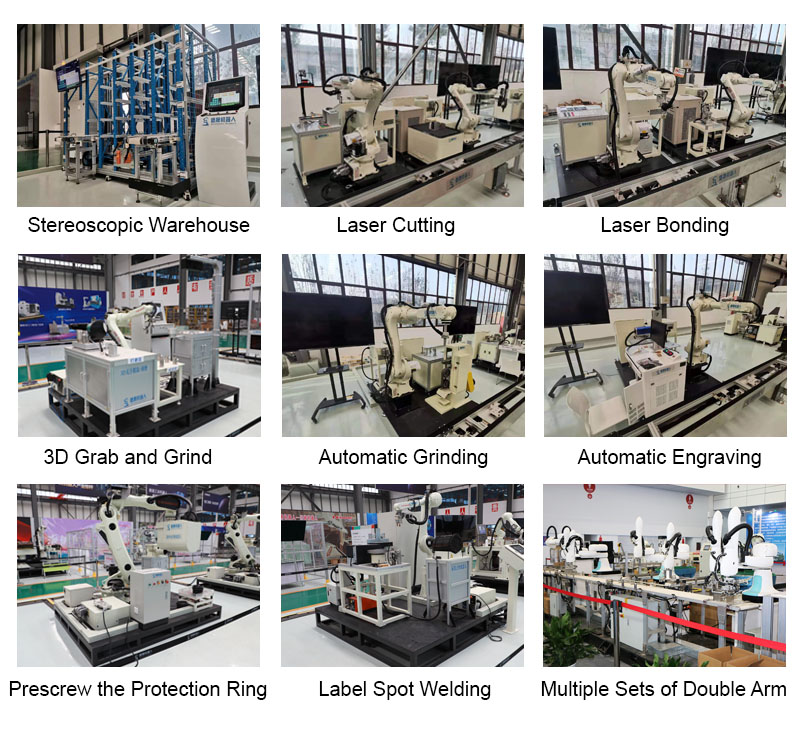

APPLICATIONS:

FEATURES:

1,Programmable Precision: The first industrial robot offered programmable precision, allowing for highly accurate and repeatable movements. This precision enabled robots to perform tasks with a level of accuracy that surpassed human capabilities, ensuring consistent results in manufacturing operations.

2,Versatility and Flexibility: The first industrial robot showcased versatility and flexibility in its applications. They could be programmed and reprogrammed to perform various tasks, making them adaptable to different manufacturing processes. This versatility allowed for cost-effective automation in a wide range of industries.

3,Increased Efficiency and Productivity: The first industrial robot significantly improved efficiency and productivity in manufacturing. With their ability to work tirelessly and with consistent precision, robots could perform tasks at a faster pace than humans. By automating repetitive and laborious tasks, industrial robots reduced production time, increased output, and improved overall operational efficiency.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: