The First Industrial Robot

Advantages of The First Industrial Robot:

1,Automation Efficiency: The First Industrial Robot significantly improved automation efficiency in manufacturing processes. It can perform repetitive tasks with high speed and accuracy, reducing human errors and increasing production output. This increased efficiency leads to improved productivity and cost savings for companies.

2,Worker Safety: The First Industrial Robot was designed with safety features to protect human workers. It is equipped with sensors and safety mechanisms to prevent accidents and ensure a safe working environment. This not only reduces the risk of injury but also enhances worker morale and job satisfaction.

3,Versatility and Adaptability: The First Industrial Robot is highly versatile and can be easily reprogrammed to perform different tasks. Its flexibility allows manufacturers to quickly adapt to changing production demands and introduce new products. This adaptability saves time and resources by eliminating the need for additional specialized machines.

The First Industrial Robot:

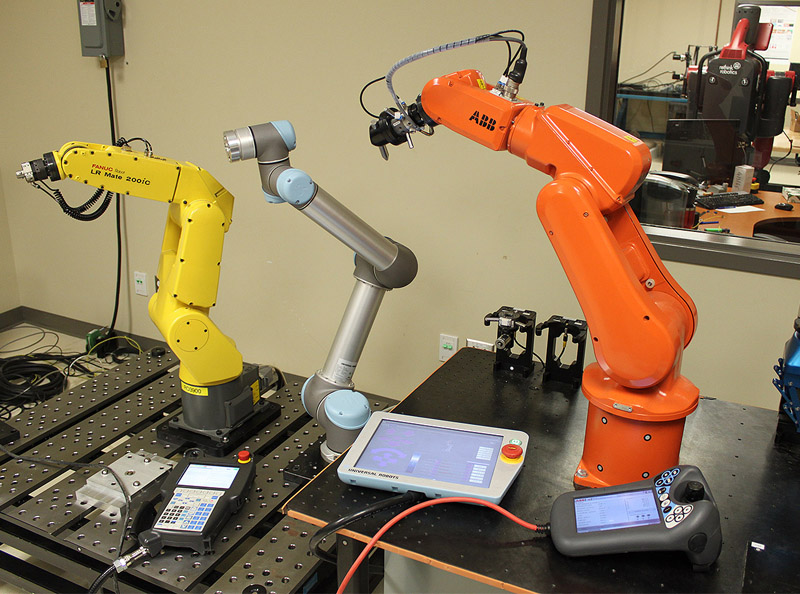

The First Industrial Robot marked a significant milestone in the history of automation. It laid the foundation for the development of subsequent industrial robots, such as the ANSI RIA R15.06 standards-compliant robots like the Dobot M1 Robot.

The First Industrial Robot introduced the concept of utilizing programmable machines to perform repetitive tasks in manufacturing. This revolutionary idea paved the way for more advanced and sophisticated robots that adhere to safety standards, such as the ANSI RIA R15.06. These standards ensure that robots are designed and operated in a way that prioritizes worker safety and mitigates potential hazards.

One such robot that adheres to these standards is the Dobot M1 Robot. It not only embodies the principles of the First Industrial Robot but also incorporates modern technologies and innovations to provide accurate and reliable performance. With its precise control and flexibility, the Dobot M1 Robot is well-suited for a wide range of industrial applications.

Overall, the First Industrial Robot kickstarted the era of automation in manufacturing, leading to the development and implementation of safer and more advanced robots like the ANSI RIA R15.06-compliant Dobot M1 Robot. These robots conform to RIA Robot Standards, ensuring both efficiency and worker safety in industrial environments.

PARAMETERS:

Model | DS-R6-08 | DS-R6-10 | DS-R6-20 | DS-R6-50 | DS-R6-165 | |

DOF | 6 | |||||

Driving Mode | AC Servo Driving | |||||

Effective Load | 8KG | 10KG | 20KG | 50KG | 165KG | |

RepeatAccuracy | ±0.05mm | |||||

Working radius | 1400mm | 1589mm | 1595mm | 1950mm | 2483mm | |

Weight | 180KG | 180KG | 290KG | 600KG | 1300KG | |

Motion | J1 | ±170 | ±170 | ±170 | ±180 | ±180 |

J2 | ±120~-85 | ±120~-80 | ±132~-95 | ±130~-90 | ±80~60 | |

J3 | ±85~-165 | ±85~-165 | ±73~-163 | ±75~-210 | ±80~-190 | |

J4 | ±180 | ±180 | ±180 | ±360 | ±360 | |

J5 | ±135 | ±135 | ±133 | ±115 | ±115 | |

J6 | ±360 | ±360 | ±360 | ±360 | ±360 | |

Max Speed(°/s) | J1 | 130 | 130 | 147 | 158 | 100 |

J2 | 130 | 130 | 100 | 149 | 90 | |

J3 | 130 | 130 | 135 | 130 | 104 | |

J4 | 270 | 270 | 300 | 215 | 144 | |

J5 | 170 | 170 | 198 | 251 | 160 | |

J6 | 455 | 455 | 194 | 365 | 215 | |

Power | 4KVA | 4KVA | 6KVA | 14KVA | 31KVA | |

Voltage | 380V or 220V | |||||

Frequency | 50Hz or 60Hz | |||||

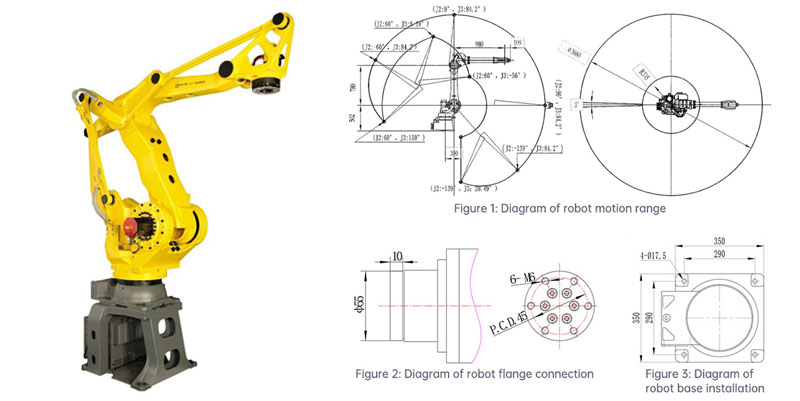

DIMENSIONAL DRAWINGS:

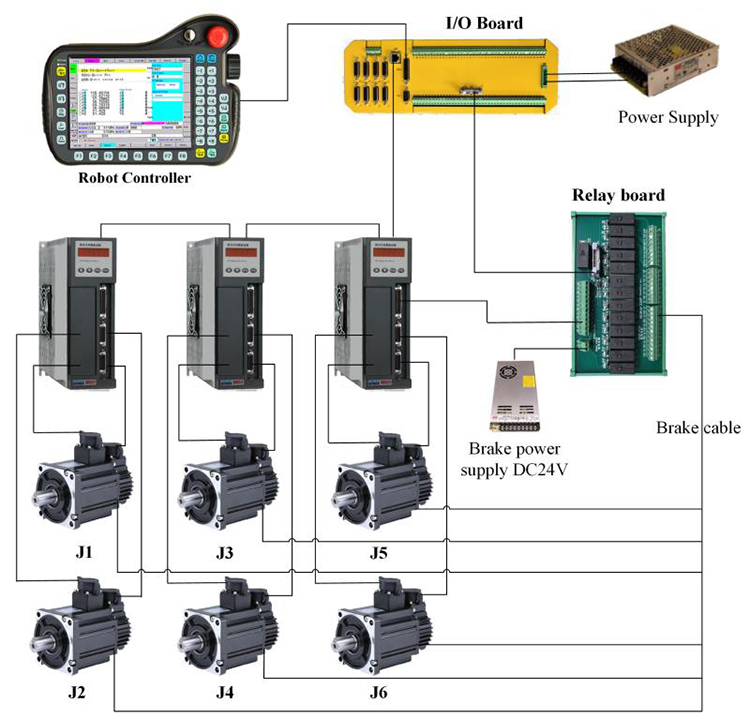

ROBOT CONTROLSYSTEM:

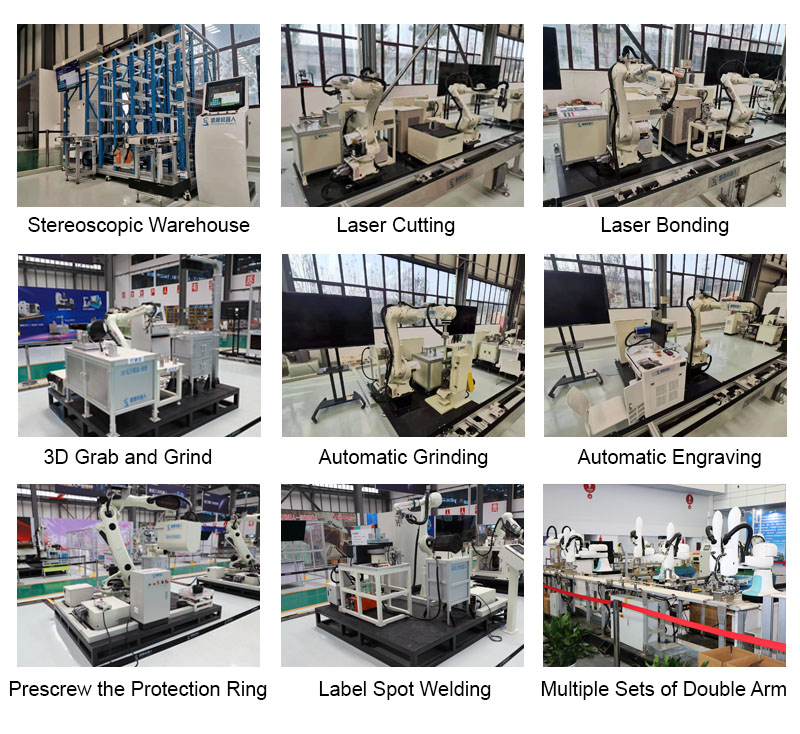

APPLICATIONS:

1,Manufacturing and Assembly: The First Industrial Robot revolutionized manufacturing and assembly processes. It enabled precise and repetitive tasks to be automated, such as welding, painting, and component assembly. This improved production efficiency, reduced errors, and increased product quality.

2,Material Handling: Material handling tasks were simplified with the introduction of the First Industrial Robot. It could lift, transport, and place heavy and bulky materials with precision and accuracy. This significantly reduced manual labor requirements and minimized the risk of injuries.

3,Hazardous Environments: The First Industrial Robot proved invaluable in hazardous environments where humans faced risks. It could be used in environments with high temperatures, toxic substances, or unstable conditions, preventing human exposure to dangerous elements. This enhanced workplace safety and mitigated potential health hazards.

FEATURES:

1,Programmability: The First Industrial Robot was programmable, allowing manufacturers to customize its actions and operations. This flexibility enabled it to perform a wide range of tasks, from simple repetitive actions to complex, multi-step processes. The ability to program the robot made it adaptable to changing production requirements, improving overall efficiency and productivity.

2,Automation: The First Industrial Robot introduced the concept of automation to manufacturing. By automating repetitive and often mundane tasks, it reduced the need for human labor, increasing efficiency and precision. This automation allowed manufacturers to streamline their processes, optimize production time, and reduce costs.

3,Physical Dexterity: The First Industrial Robot was designed to have physical dexterity, with multiple degrees of freedom and the ability to manipulate objects with precision. It could perform tasks that required delicate handling or precise movements, such as assembly or material handling. This dexterity made the robot a valuable addition to manufacturing processes, improving accuracy and consistency.

OUR SERVICE:

PACKAGE AND SHIPPING:

CERTIFICATIONS:

COOPERRATION PARTNER:

EXHIBITION:

MORE PRODUCTS:

CONTACT US: