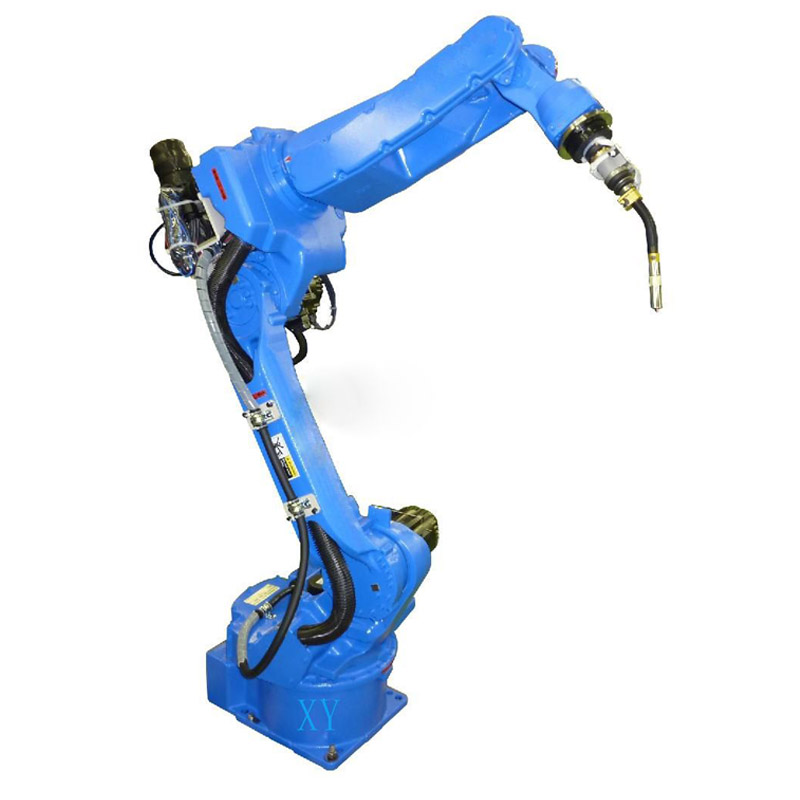

Tig Welding Robot

Tig Welding Robot

The advantages of Tig Welding Robot include improved precision and accuracy in welding, increased productivity and efficiency, enhanced safety for workers, and the ability to work in hazardous or hard-to-reach areas. The robot's consistent and stable arc ensures high-quality welds, reducing the need for rework. It can also perform complex welding tasks with ease, leading to faster production times. Additionally, the robot's automation reduces the risk of human error and minimizes the exposure of workers to harmful fumes and radiation. Overall, Tig Welding Robot offers numerous benefits for industries seeking to optimize their welding processes.

Tig Welding Robot

Tig Welding Robot, Robotic Laser Welding, Daihen Welding Machine, and Robotic Welding in the Automotive Industry are all advanced technologies that have revolutionized welding processes.

Tig Welding Robot is a robotic system that uses Tungsten Inert Gas (TIG) welding technique. It offers high precision and accuracy, making it ideal for welding applications in the automotive industry. This robot can perform complex welds with ease, ensuring consistent quality and reducing human error.

Robotic Laser Welding is another cutting-edge technology used in the automotive industry. It utilizes laser beams to weld metal parts together. This technique provides excellent control and speed, resulting in strong and durable welds. Robotic Laser Welding is widely used in automotive manufacturing due to its efficiency and versatility.

Daihen Welding Machine is a brand known for its high-quality welding equipment. Their machines are widely used in the automotive industry for their reliability and performance. Daihen Welding Machines offer various welding processes, including TIG, MIG, and spot welding, catering to different automotive welding needs.

Robotic Welding in the automotive industry has significantly improved productivity and efficiency. With the use of robots, welding processes can be automated, reducing labor costs and increasing production output. These robots can handle heavy and repetitive tasks with ease, ensuring consistent quality and reducing the risk of accidents.

In conclusion, the integration of Tig Welding Robot, Robotic Laser Welding, Daihen Welding Machine, and Robotic Welding in the Automotive Industry has transformed the welding processes. These advanced technologies have improved precision, speed, and efficiency, making them crucial in the automotive manufacturing sector.