Shipbuilding Robotics Solution

Shipbuilding Robotics Solution:

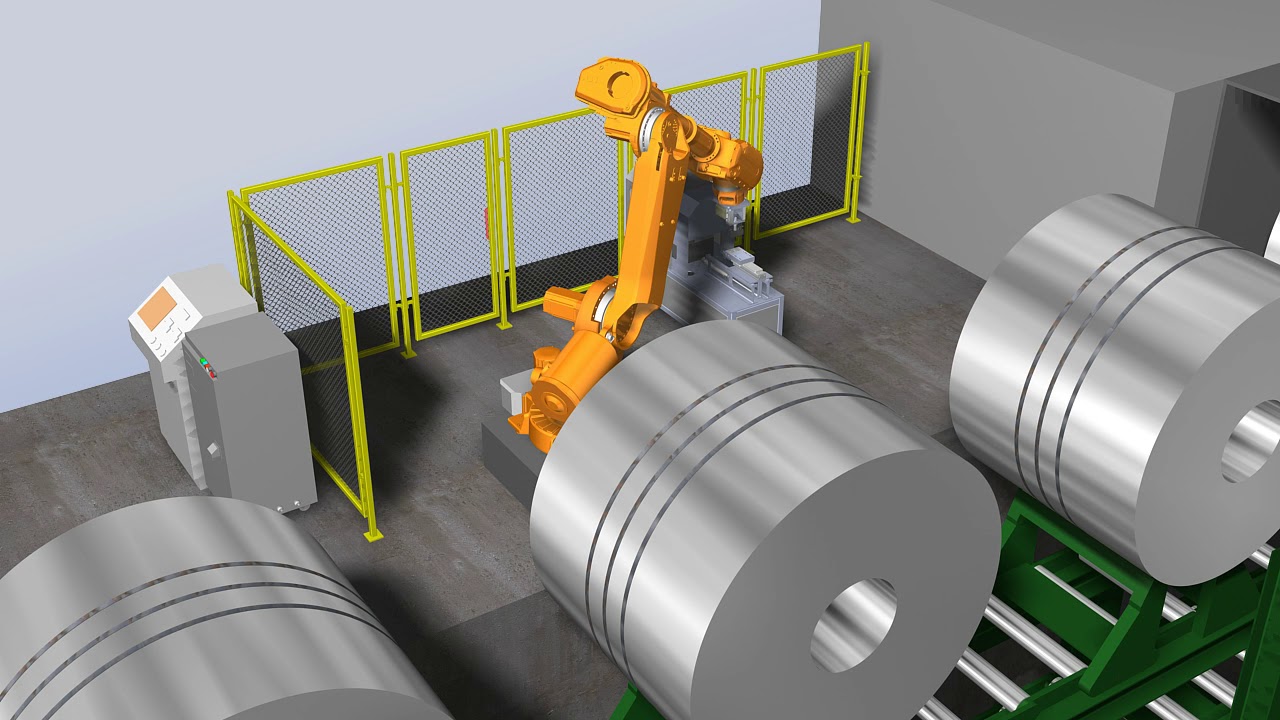

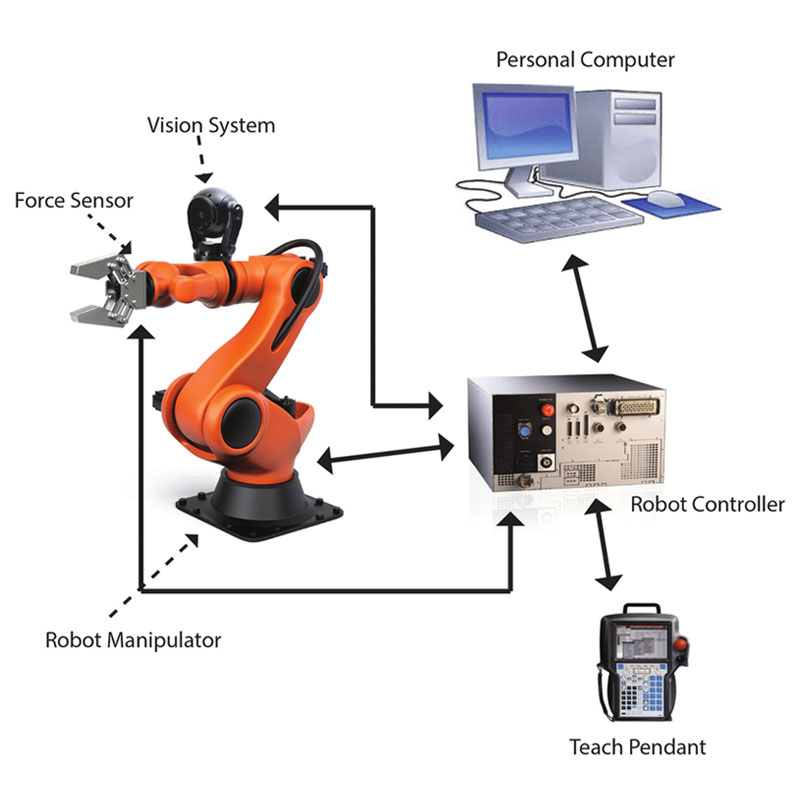

Shipbuilding robotics solutions offer several advantages in the shipbuilding industry. Firstly, they enhance productivity by automating various tasks, such as welding, painting, and material handling, reducing the reliance on manual labor. This leads to faster production cycles and increased output. Secondly, robotics solutions improve precision and quality in shipbuilding processes, resulting in higher levels of accuracy and consistency in welding and assembly tasks. Additionally, these solutions enhance worker safety by taking on hazardous or physically demanding tasks. Overall, shipbuilding robotics solutions contribute to improved efficiency, quality, and safety in the shipbuilding industry.

Shipbuilding Robotics Solution:

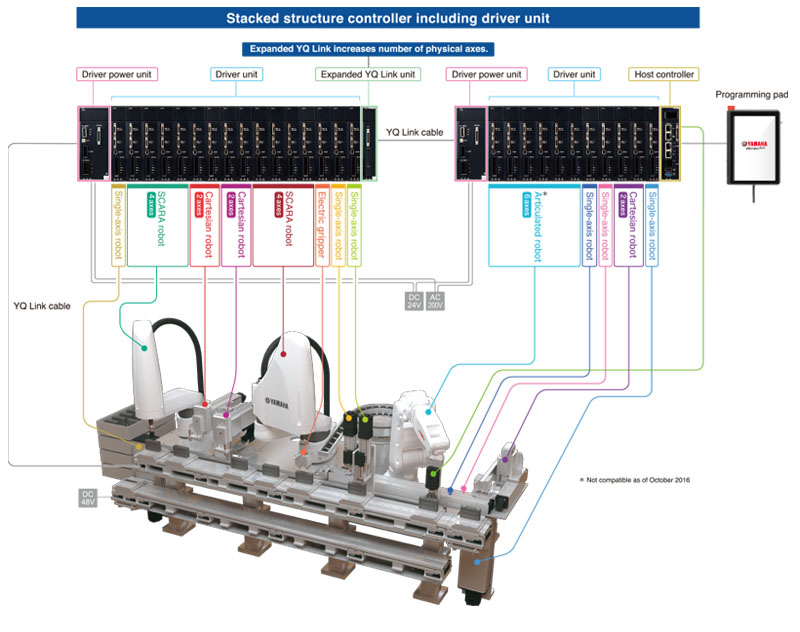

Shipbuilding robotics solutions have improved the efficiency of shipbuilding processes dramatically. Scara robots, Kuka robots, and ROS Industrial Kuka robots are all examples of robotic solutions that can be used in shipbuilding. These solutions provide a range of automated functions, such as welding, cutting, and painting, that help reduce the amount of time and labor required to complete a project. Additionally, these robots can be programmed to perform complex tasks, such as robotic welding, which increases their efficiency and accuracy. The Kuka LBR IIWA robot is an example of a robot specifically designed for shipbuilding and is capable of performing a variety of tasks, such as welding, cutting, and painting. This robot is equipped with a robotic arm and laser cutting capabilities that make it an invaluable asset to any shipbuilding project.

Robotics solutions for shipbuilding have revolutionized the industry, allowing projects to be completed faster and more efficiently than ever before. By utilizing these solutions, shipbuilders are able to reduce costs and increase the quality of their projects. As technology continues to develop, it is likely that the use of robotics in shipbuilding will only continue to increase.