Robots For Mining

Robots For Mining:

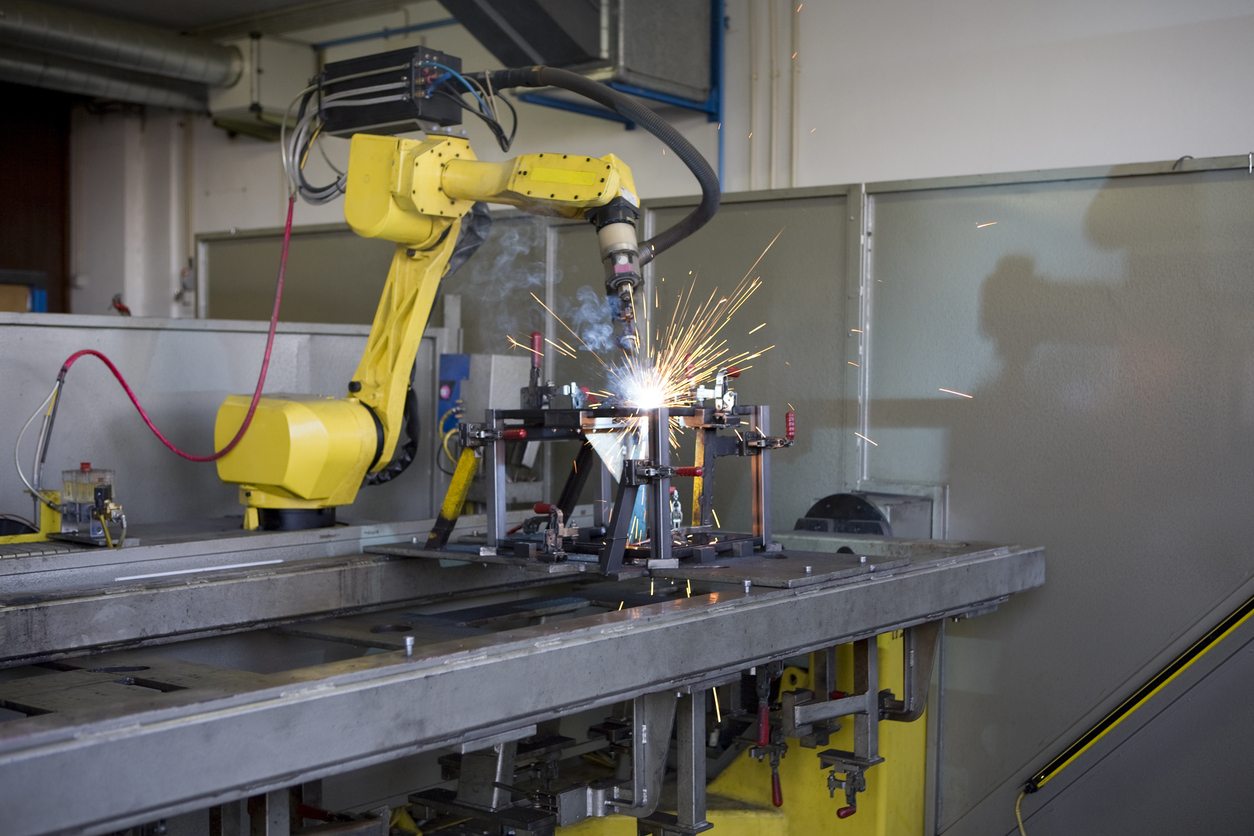

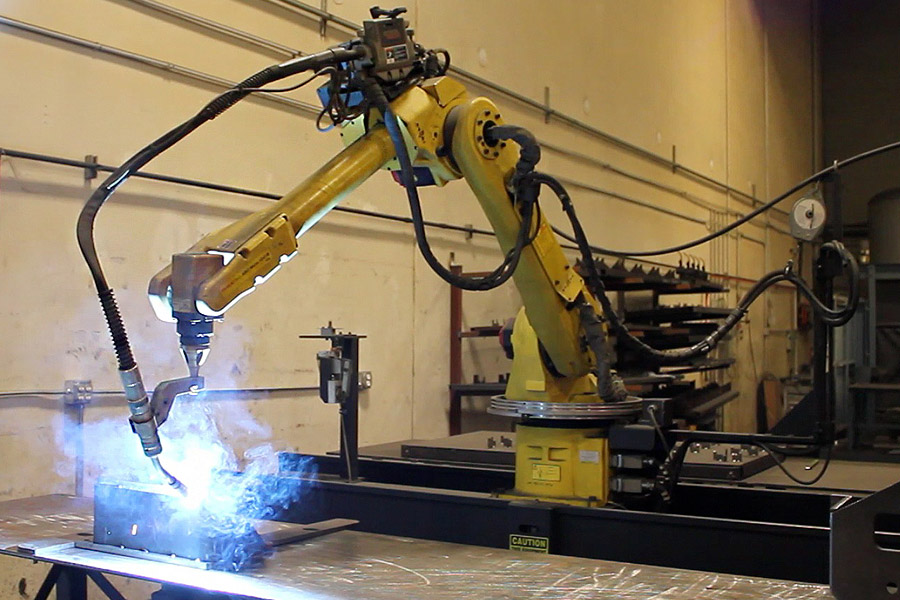

Robots for mining offer numerous advantages in the mining industry. First and foremost, these robots enhance safety by eliminating the need for human workers to carry out hazardous tasks in dangerous environments. They can be remotely operated or work autonomously, reducing the risk of injuries and fatalities.

Additionally, mining robots improve efficiency and productivity. They can work continuously without the limitations of human fatigue, resulting in optimized operations and increased output. These robots can perform tasks with great precision, such as drilling, excavation, and transportation, leading to higher accuracy and reduced material waste.

Moreover, robots are equipped with advanced sensing and imaging technologies that allow them to gather real-time data and perform data analytics. This enables better decision-making, enhanced resource management, and improved operational planning.

Robots for mining also contribute to environmental sustainability. By minimizing extraction errors and reducing the environmental impact of mining activities, they promote responsible and eco-friendly practices. Additionally, these robots can access hazardous or hard-to-reach areas without causing further disturbance to the surrounding ecosystems.

In summary, the advantages of robots for mining include improved safety, enhanced efficiency and productivity, advanced data capabilities, and environmental sustainability. These robots offer a promising future for the mining industry, revolutionizing the way mining operations are conducted.

Robots For Mining:

Robots for Mining, Robotics in the Garment Industry, Tech Robotics Automation, and Industrial Robot Suppliers are all prominent players in the field of industrial automation.

Robots for Mining specialize in developing robots for the mining industry that enhance safety, efficiency, and productivity. By automating hazardous tasks, they reduce the risk to human workers and optimize mining operations.

In the garment industry, Robotics in the Garment Industry has revolutionized production processes. These robots streamline tasks such as fabric cutting, sewing, and quality control. They ensure precision, speed, and consistency, ultimately improving productivity and reducing costs.

Tech Robotics Automation has emerged as a leader in providing advanced automation solutions across various industries. Their robots are equipped with cutting-edge technologies such as artificial intelligence and machine learning, enabling them to adapt to dynamic environments and perform complex tasks.

Industrial Robot Suppliers encompass a range of top manufacturers in the field, including names like Fanuc, ABB, KUKA, Yaskawa, and Universal Robots. These suppliers offer a diverse array of industrial robots tailored to different industries and applications, driving efficiency, innovation, and productivity in manufacturing processes.

In conclusion, Robots for Mining, Robotics in the Garment Industry, Tech Robotics Automation, and Industrial Robot Suppliers are key players shaping the future of industrial automation. Through their innovative solutions and technologies, they are revolutionizing various sectors and optimizing operations on a global scale.