Robots In Food Production

Robots In Food Production:

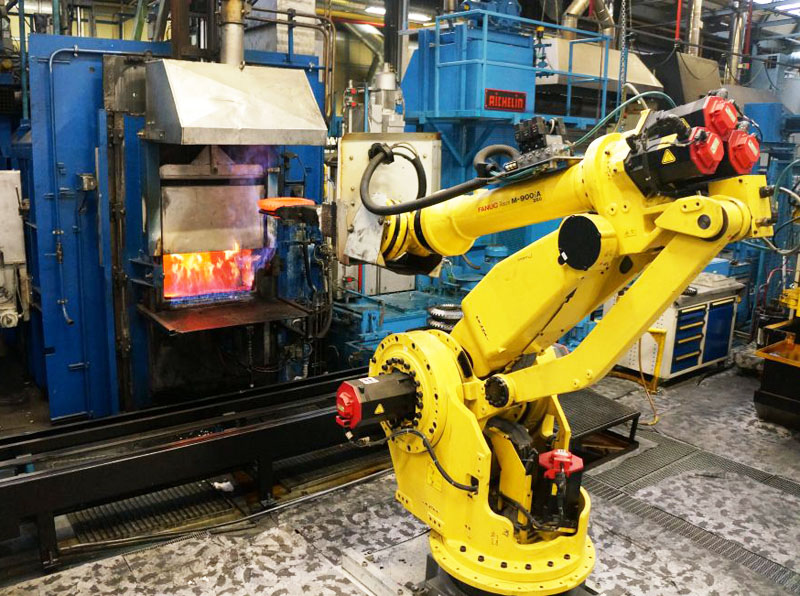

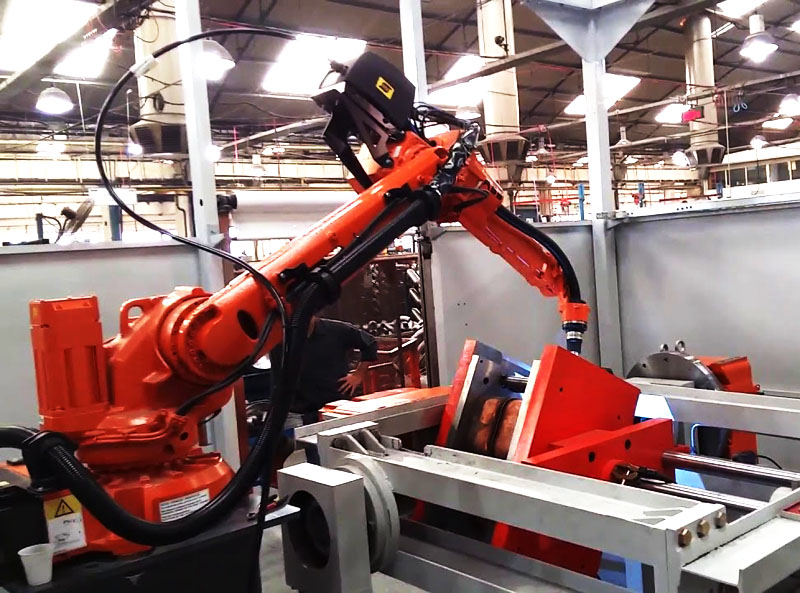

The advantages of Robots in Food Production are numerous. Firstly, robots can work 24/7 without the need for breaks or rest, leading to increased productivity and efficiency. Secondly, robots can perform repetitive tasks with utmost precision, ensuring consistent quality in food production. Additionally, robots reduce the risk of contamination and improve food safety by minimizing human contact with the food. Moreover, robots can handle heavy loads and work in hazardous environments, reducing the risk of injuries for human workers. Overall, Robots in Food Production offer a faster, safer, and more reliable method of food processing.

Robots In Food Production:

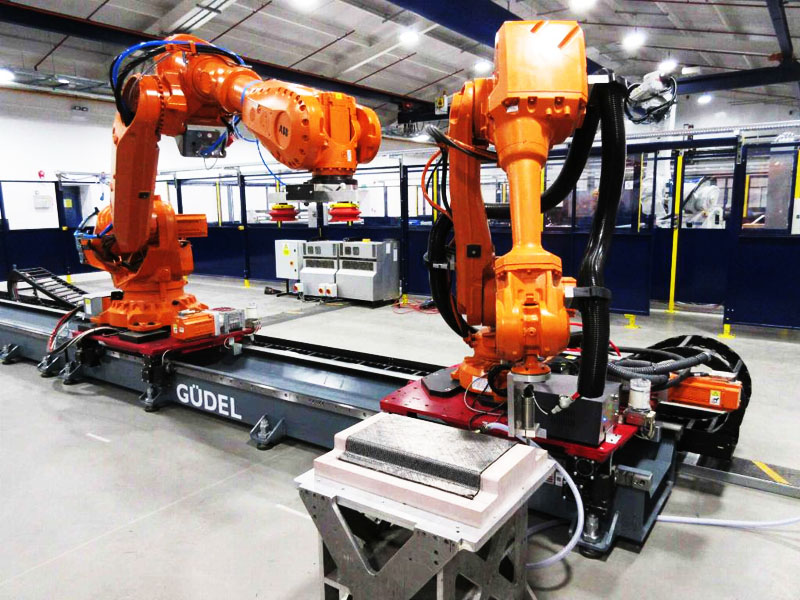

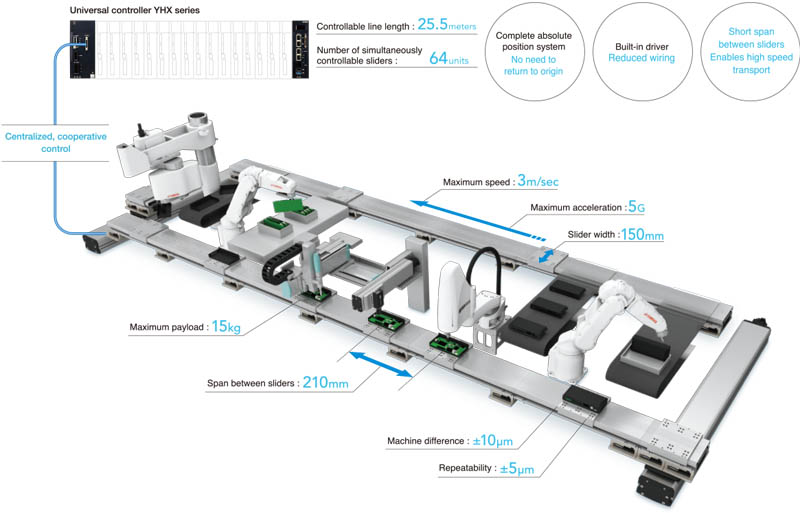

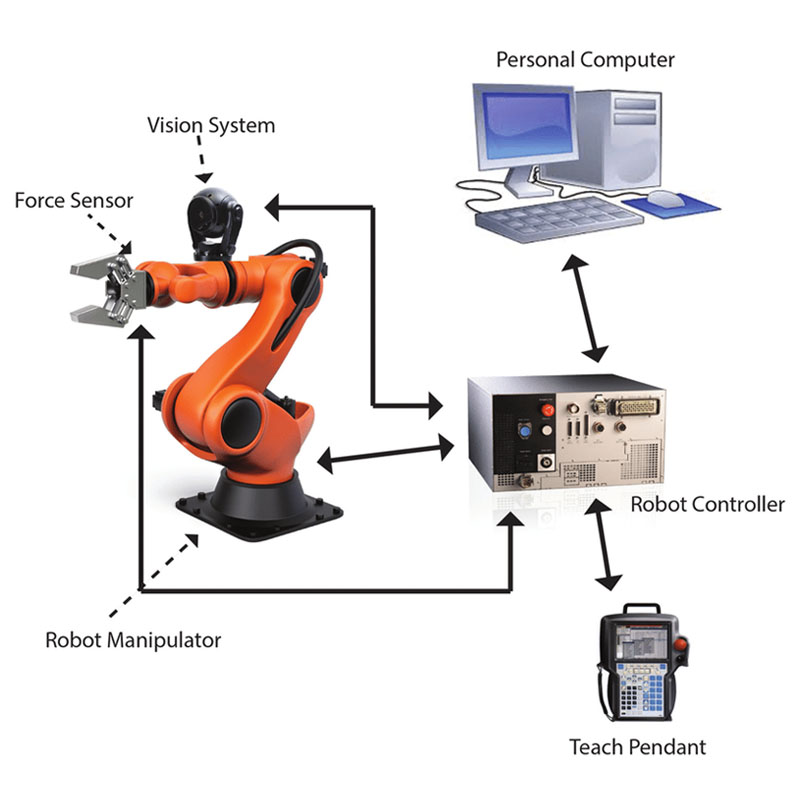

The Japanese robotics industry has always been at the forefront of technological innovation, and one area where they have excelled is in food production. With the introduction of robots in food production, companies have been able to streamline their processes and improve efficiency. One such example is the low-cost industrial robot, Kuka Kr 270. This robot has revolutionized the industry with its advanced features and affordable price point. Its precision and versatility have made it a popular choice for many food production companies. The combination of Japanese ingenuity and robotic technology has truly transformed the way we produce food.