Robotics In Garment Manufacturing

Robotics In Garment Manufacturing:

Robotics in garment manufacturing is becoming increasingly popular due to its advantages. Firstly, robots can operate with greater speed and accuracy than humans. This allows for higher production rates with fewer errors, resulting in increased efficiency and reduced costs. Secondly, robots are able to complete tasks that are too hazardous for humans. This includes tasks that involve hazardous materials, extreme temperatures, and repetitive motions. Thirdly, robots can be programmed to perform complex tasks that require a high degree of precision. This reduces the need for manual labor and increases the accuracy of the finished product. Finally, robots use less energy than humans, reducing energy costs and carbon emissions. All of these advantages make robotics in garment manufacturing an attractive option for businesses.

Robotics In Garment Manufacturing:

Robotics has been increasingly used in various industries as technology advances, with garment manufacturing, Alstom inspection, and medical engineering being some of the sectors that have seen the most advances.

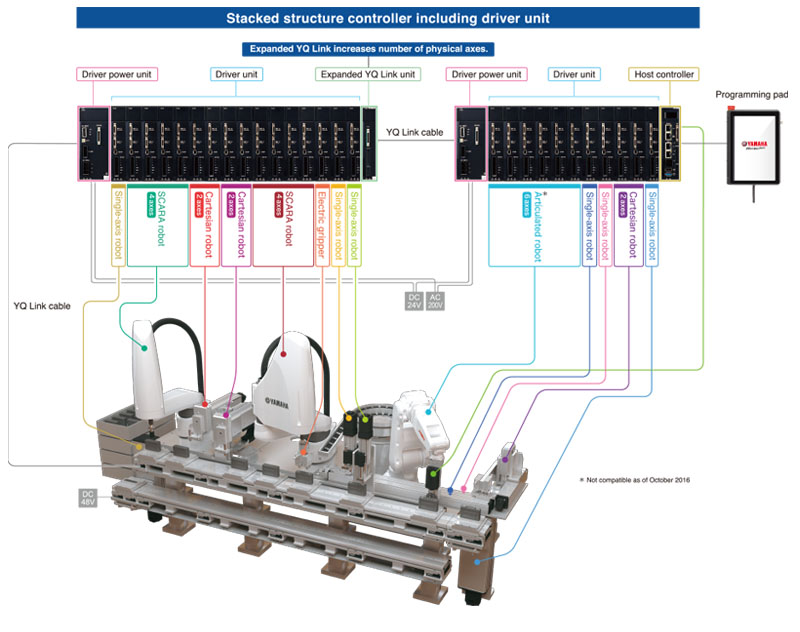

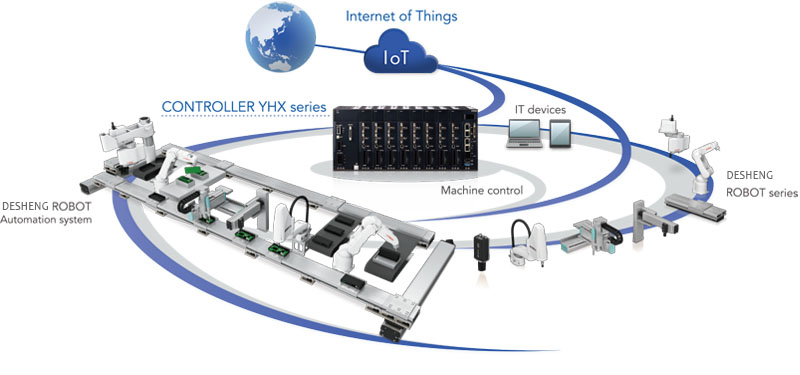

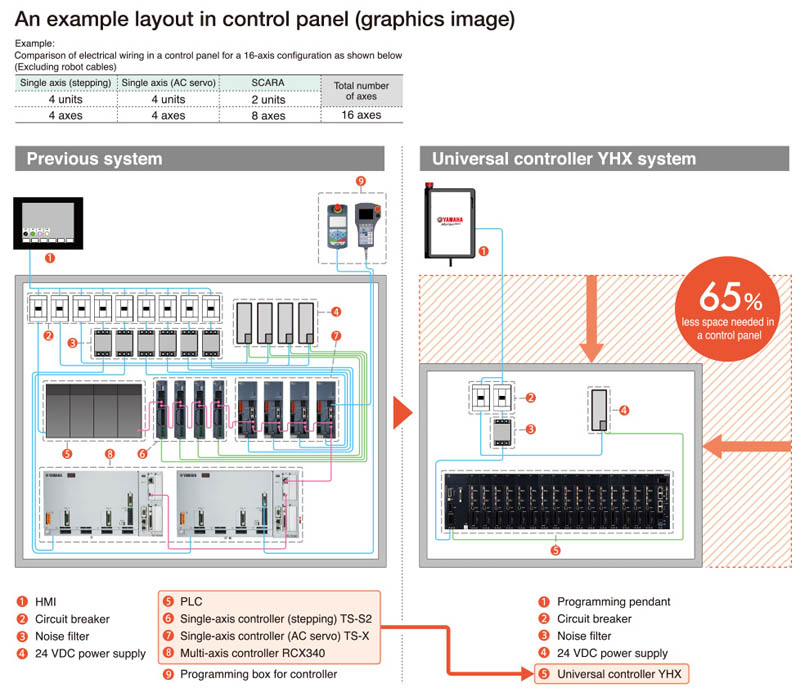

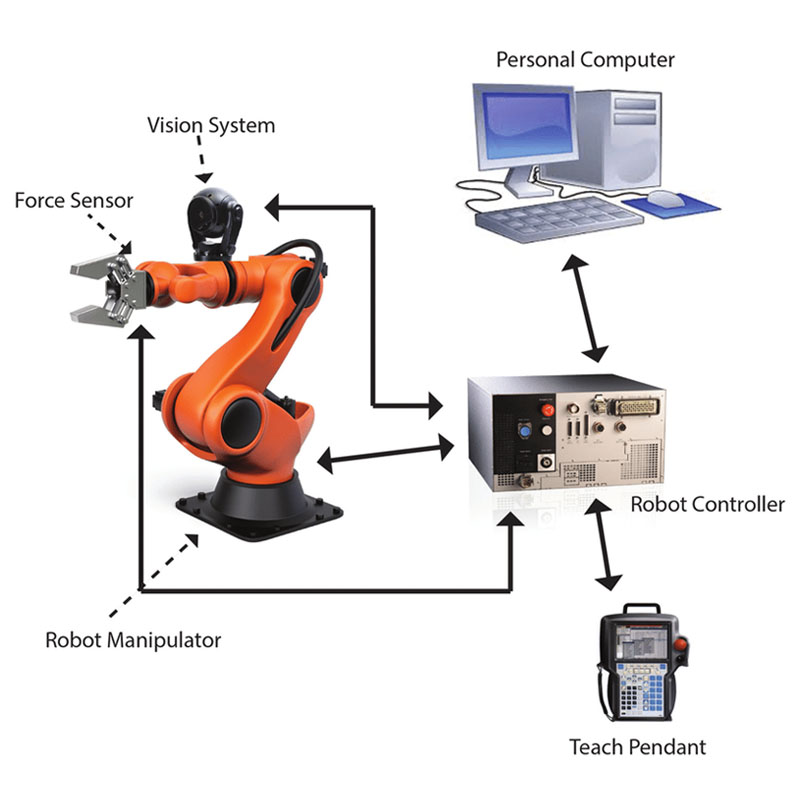

Robotics in garment manufacturing is used to automate the production of garments. By using robots, the industry can produce garments with greater accuracy and speed than manual labor. The robots can also be programmed to handle complex tasks, such as creating intricate patterns and stitching.

Alstom inspection robotics is used to inspect railroad networks, bridges, and other infrastructure. The robots can detect flaws and defects that would be difficult for humans to detect, and they can move quickly and safely around the infrastructure.

The UR5 robot cost is a fraction of what traditional robots cost, making it a cost-effective solution for many industries. The robot is easy to program and can be used to automate a variety of tasks.

Medical robotics engineering is used to create robots that can assist in the diagnosis and treatment of medical conditions. The robots can be used to perform delicate and complex surgeries, as well as to monitor patients and provide them with personalized care.

Overall, robotics has been instrumental in revolutionizing various industries, from garment manufacturing to medical engineering. As technology continues to advance, robotics will continue to be a major player in the future of automation.