Robotics In Automotive Manufacturing Solution

Robotics In Automotive Manufacturing Solution:

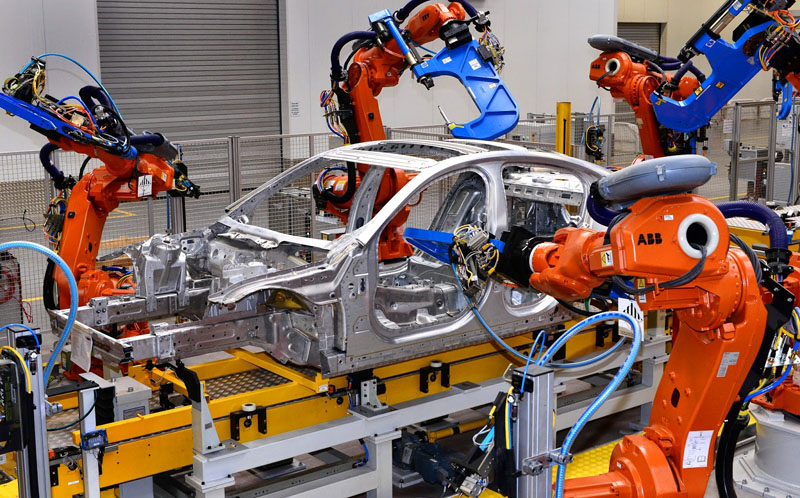

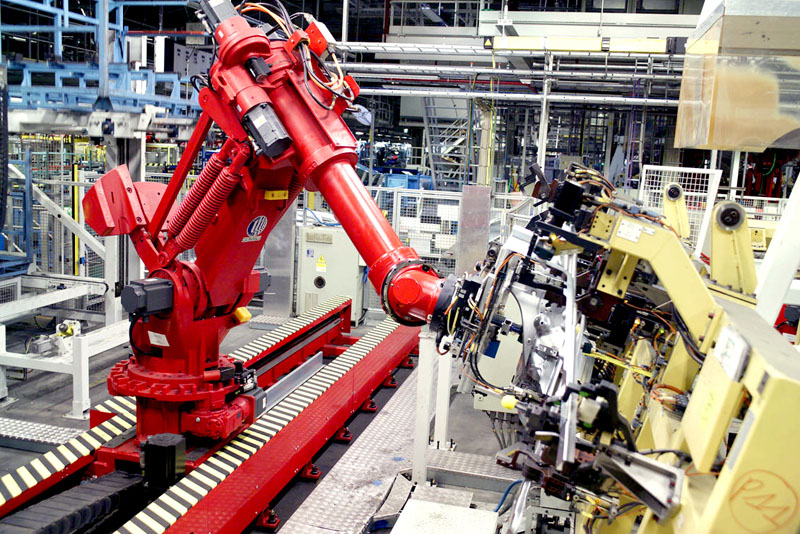

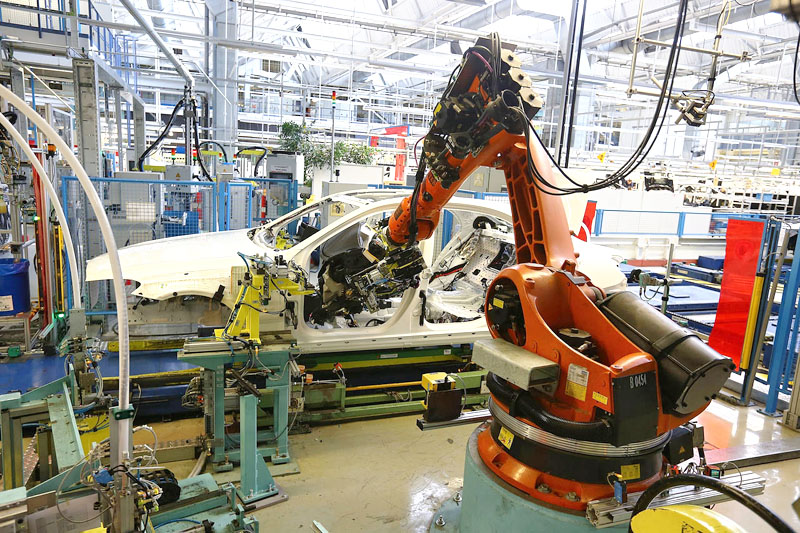

1,Increased productivity: Robotics in automotive manufacturing can significantly increase productivity by automating repetitive tasks and working at a consistent pace without breaks or fatigue. This leads to higher production rates and shorter cycle times.

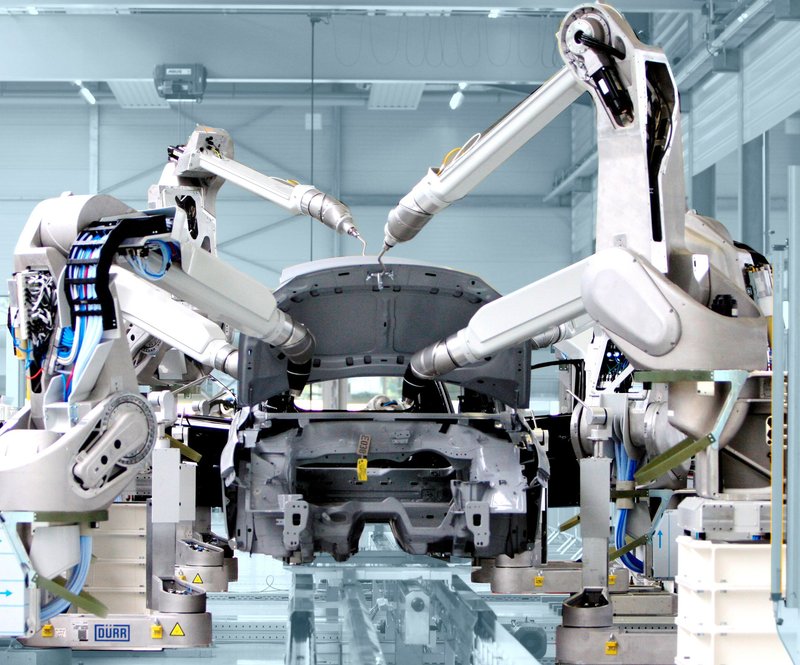

2,Improved accuracy and quality: Robots can perform tasks with precision and accuracy, resulting in higher quality products. They can consistently repeat movements and measurements, reducing errors and inconsistencies in the manufacturing process.

3,Enhanced safety: By automating hazardous or physically demanding tasks, robotics in automotive manufacturing can improve worker safety. Robots can handle heavy materials or work in hazardous environments, reducing the risk of accidents or injuries for human workers. This creates a safer working environment overall.

Please Contact Us For Detailed Technical Parameters.

Robotics In Automotive Manufacturing Solution:

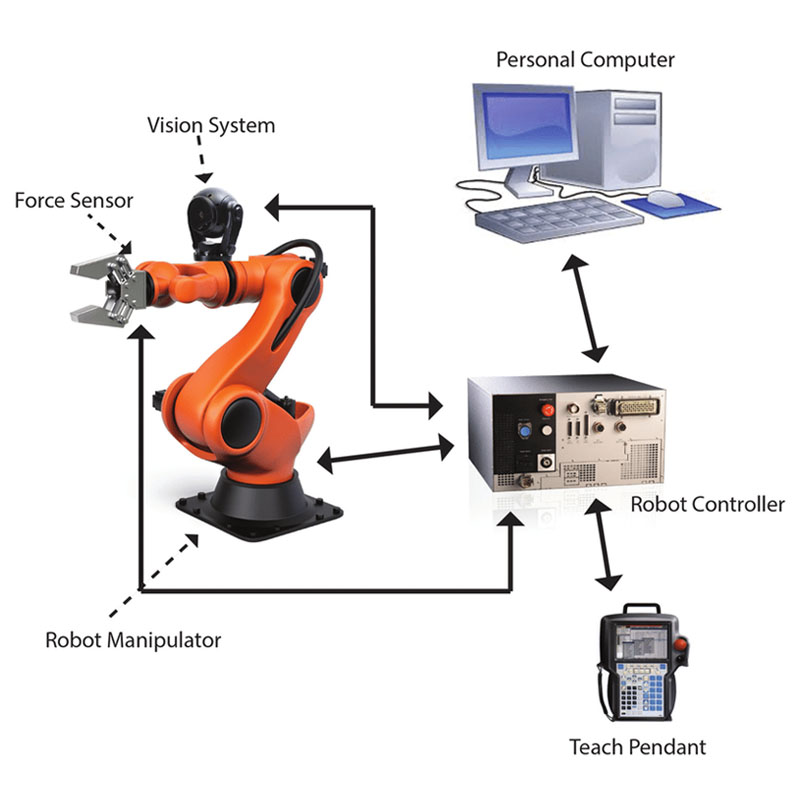

The automotive manufacturing industry has witnessed a significant transformation with the integration of robotics. Robotic arms have become an essential part of car manufacturing, revolutionizing the production process. With their precise movements and capabilities, robotic arms contribute to increased productivity, higher quality, and improved safety. These advanced machines perform tasks such as welding, assembly, and painting with unparalleled accuracy and efficiency. China, being a prominent player in the automotive industry, has embraced robot technology in car manufacturing. As technology continues to advance, the role of robotic arms in the automotive industry will continue to expand, shaping the future of car manufacturing worldwide.